- Overview

- Detailed Photos

- Product Parameters

- FAQ

Basic Info.

Packaging & Delivery

Product Description

Features:

The machine is of wide closure-type frame, which is solid, receiving tempering treatment. It has following features:

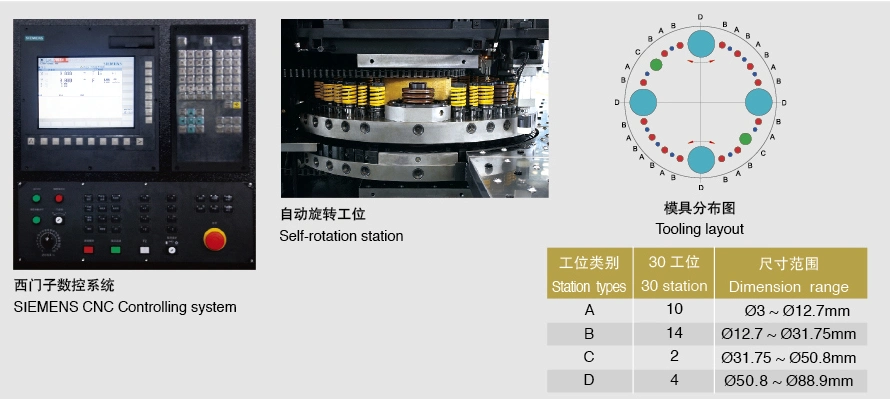

> Streamline body with side pin-positioning, sleeve structure and thick turret, accurate positioning, good guiding, high accuracy adjustable worm and gear mechanism, servo motor and quiet.

> Main transmission mechanism with cranked rod, powerful and convenient Japanese FANUC Oip CNC controller, long ballscrew and guideway with high speed, universal pneumatic and electrical parts, auto floating clamp and stainless worktable with steel ball and brush on it.

| Type | ETP-20/30 | |||||

| Nominal Force | kN | 200/300 | ||||

| Sheet Size( Include One Repositioning) | mm | 1250x2500 | 1250x4000 | 1250x5000 | 1500X4000 | 1500X5000 |

| slide stroke | mm | 32 | ||||

| Max. Plate Thickness | mm | 6.35 | ||||

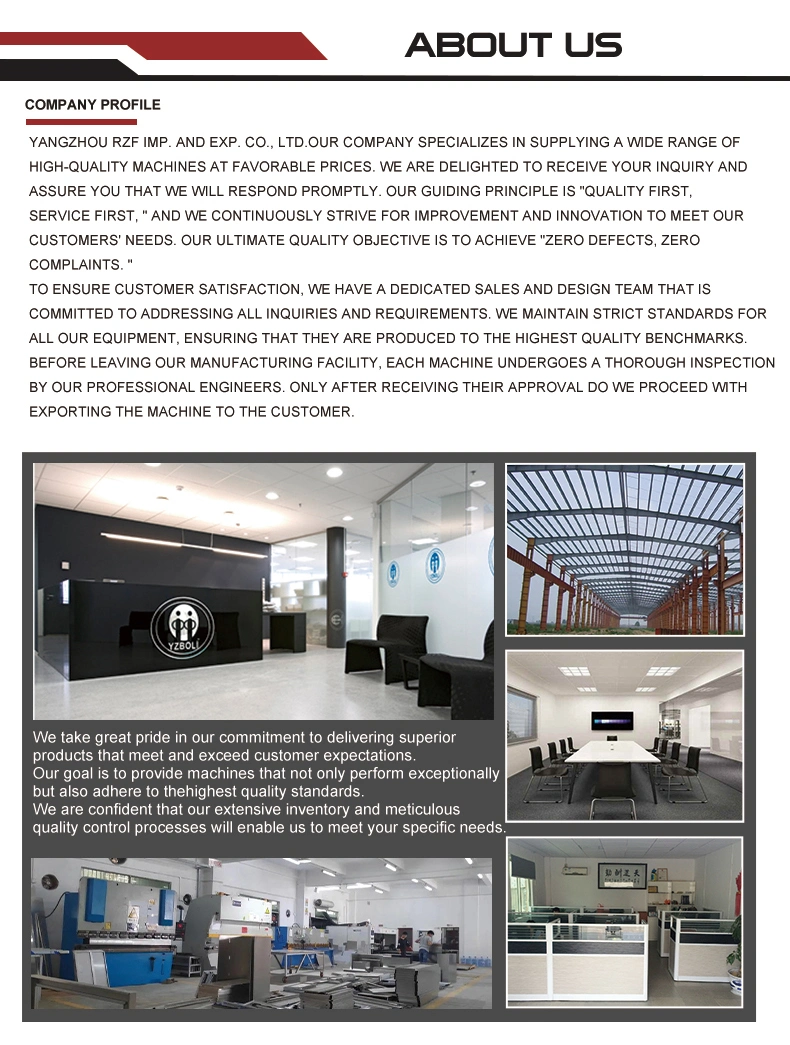

| Max. punching dia. | mm | Φ 88.9 | ||||

| station | qty | 30 | ||||

| punching Accuracy | mm | ±0.1 | ||||

| Punching Frequency | hpm | 600 | ||||

| Max. feeding speed | m/min | 106 | ||||

| frame structure | closed | |||||

| controlling axis | qty | 5 | ||||

| turret speed | r/min | 30 | ||||

| Max. punching dia. Of rotary station | mm | Φ 88.9 | ||||

| max. sheet weight | kg | 156 | 156 | 210 | 210 | 235 |

| air pressure | mpa | 0.55 | ||||

| Outline Dimension(LXWXH) | mm | 5200x2700x2100 | 5200x4200x2100 | 5200x5200x2100 | 5700x4200x2100 | 5700x5200x2100 |

Q1: What is the purpose of a CNC Mechanical Turret Punch?

A1: A CNC Mechanical Turret Punch is used for punching holes, shapes, and designs in sheet metal with high precision and speed.

Q2: What are the key features of a CNC Mechanical Turret Punch?

A2: The key features of a CNC Mechanical Turret Punch include CNC control, a rotating turret with multiple punch tools, high-speed punching capabilities, and advanced tooling options.

Q3: What are the advantages of using a CNC Mechanical Turret Punch?

A3: The advantages of using a CNC Mechanical Turret Punch include increased productivity, precise and consistent punching results, reduced material waste, and the ability to handle complex designs.

Q4: Can you provide some details about the punching process?

A4: The CNC Mechanical Turret Punch uses a combination of punching tools mounted on a rotating turret to pierce holes, create shapes, and form designs on sheet metal. The CNC control system ensures accurate positioning and punching.

Q5: How does a CNC Mechanical Turret Punch ensure accuracy?

A5: The CNC control system allows for precise programming of punching parameters, such as hole size, shape, and position, ensuring high accuracy in the punched parts.

Q6: What are the specific applications of a CNC Mechanical Turret Punch?

A6: A CNC Mechanical Turret Punch is widely used in industries such as automotive, electronics, construction, and manufacturing for applications like electrical enclosures, metal cabinets, panels, and signage.

Q7: What are the key details to consider when choosing a CNC Mechanical Turret Punch?

A7: Key details to consider include the maximum sheet size and thickness the machine can handle, the number and type of available punch tools, the CNC control system capabilities, and the machine's overall reliability.

Q8: How can a CNC Mechanical Turret Punch contribute to operational efficiency?

A8: A CNC Mechanical Turret Punch offers fast setup times, high punching speeds, and automation capabilities, resulting in increased productivity, reduced labor costs, and improved overall efficiency.