Basic Info.

Power Source

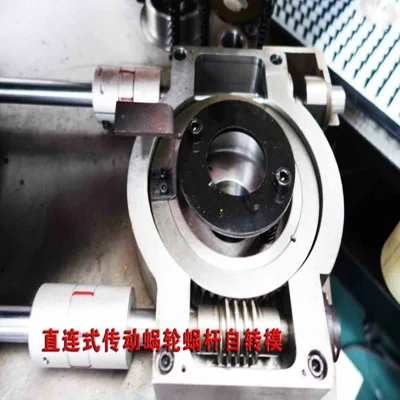

Mechanical Drive

Precision

High Precision

Certification

GS, CE, ISO 9001

Condition

New

Throat Depth

1250/1500/2000mm

Transport Package

Pallet

Specification

5000*5000*2100mm

Trademark

Richocean

Origin

Qingdao China

HS Code

8462411900

Production Capacity

100sets/Month

Product Description

JT30 series Mechanical CNC turret punch press

Main technical parameters:

Product features:

1.Machine body,welded parts and casted parts have been high-temperature,with internal stress relieved,and without deformation;the spacing of guide rails at Y-direction have been widened,realizing stable feeding.

2.Japanese technology of thin turret bushing is adopted,with light weight,stable running and good guiding performance.

3.Italian-brand pneumatic friction clutch and double-valve control system is adopted,with excess-tonnage cutout safety device.

4.Composite table face with universal-joint ball and brush is adopted,which can effectively protect the blank;Guide rails and lead screws are dust-proof designed,which can effectively protect the sliding blocks of guide rail and balls of screw nut,and prolong their service life.

5.With automatic repositioning function,and able to realize machining without blind zone.

6.Imported-brand servo-motor and electrical elements are adopted,with stable performance;Guide rails and lead screws are all imported from Taiwan.

7.Drawing with AutoCAD,and machining program can beautomatically generated,with automatic mold selection function.

8.The punching is designed in high and low speed,which can satisfy themachining demand of different materials,thickneses and processes.

9.Control cabinet and electrical cabinet are isolated,avoiding electromagnetic interference,and easy for operation.

Main technical parameters:

| No. | Name | Parameter | Unit | Note |

| 1 | Punch force | 300(30) | KN(T) | |

| 2 | Rack structure | O-shaped closed-type | mm | Electric frnace tempering |

| 3 | Max.processing size | X-axis 2500 Y-axix 1250 | mm | Secondary positioning Able to process 5000mm |

| 4 | Max.processing thickness | 4 | mm | |

| 5 | Max.punch diameter | φ88.9 | mm | Non-standard customization |

| 6 | Max hit speed | 280 | Times/minute | |

| 7 | Repositioning cylinder | 2 | Sets | |

| 8 | No.of control shafts | 3/4(X,Y,T,Z) | PCs | Rotary station(optional) |

| 9 | Mold type | Long guide 85 series international standard mold | ||

| 10 | Turret station distribution | A,B,C,D | Standard equipped | Non-standard customization |

| 11 | Mold processing life | 500 thousand | Times | |

| 12 | Max.feeding speed | X-axis 80/Y-axis 80 | m/min | |

| 13 | Table structure | Seamless brush/universal-jiot steel-ball table composite face | Stainless steel edged | |

| 14 | Max.turret speed | 40 | rpm | |

| 15 | Punching accuracy | 0. | mm | |

| 16 | Max.load weight | 150 | Kg | |

| 17 | Max.output piower | 15.5 | KW | |

| 18 | Air supply pressure | 0.55 | Mpa | |

| 19 | Power supply | 380±5% | V | |

| 20 | Outline dimension | Length X width X height 5000x5000x2100 | Mm |

Product features:

1.Machine body,welded parts and casted parts have been high-temperature,with internal stress relieved,and without deformation;the spacing of guide rails at Y-direction have been widened,realizing stable feeding.

2.Japanese technology of thin turret bushing is adopted,with light weight,stable running and good guiding performance.

3.Italian-brand pneumatic friction clutch and double-valve control system is adopted,with excess-tonnage cutout safety device.

4.Composite table face with universal-joint ball and brush is adopted,which can effectively protect the blank;Guide rails and lead screws are dust-proof designed,which can effectively protect the sliding blocks of guide rail and balls of screw nut,and prolong their service life.

5.With automatic repositioning function,and able to realize machining without blind zone.

6.Imported-brand servo-motor and electrical elements are adopted,with stable performance;Guide rails and lead screws are all imported from Taiwan.

7.Drawing with AutoCAD,and machining program can beautomatically generated,with automatic mold selection function.

8.The punching is designed in high and low speed,which can satisfy themachining demand of different materials,thickneses and processes.

9.Control cabinet and electrical cabinet are isolated,avoiding electromagnetic interference,and easy for operation.