- Overview

- Detailed Photos

- Product Description

- Processing and Manufacturing

- Reference Products Photos

- Our Clients

Basic Info.

Model NO.

FMC-3058

Controlling Mode

CNC

Automatic Grade

Automatic

Power Source

Mechanical Drive

Precision

High Precision

Certification

GS, CE, ISO 9001

Condition

New

L/UL System

1500mm*3000mm

CNC Turret Punch Machine

Hpe-3058-40la2

CNC System

Siemens(840d)

Software

Israel Cnckad

Tool Stations

40

Max. Processing Sheet Size

1500*5000mm

Optional 01

Tool Lift Assist Device

Optional 02

Oil Mist Protection Device

Transport Package

Steel Pallet with Waterproof Cloth

Specification

30 Tons

Trademark

BHTIE

Origin

China

HS Code

8462991000

Production Capacity

30 Sets / Month

Product Description

|  |

|  |

| |

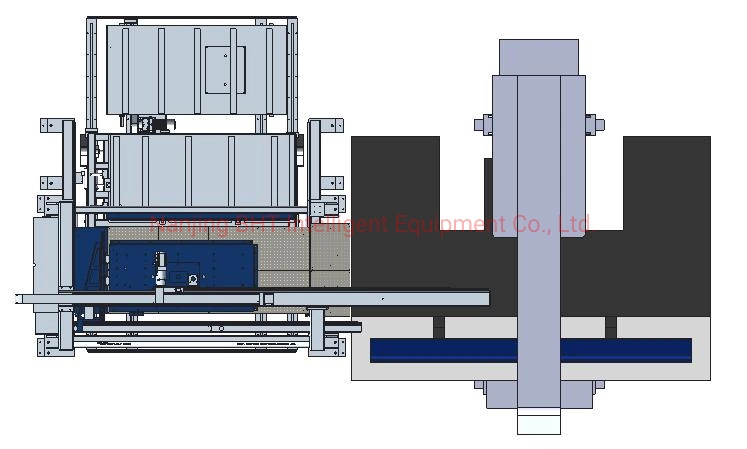

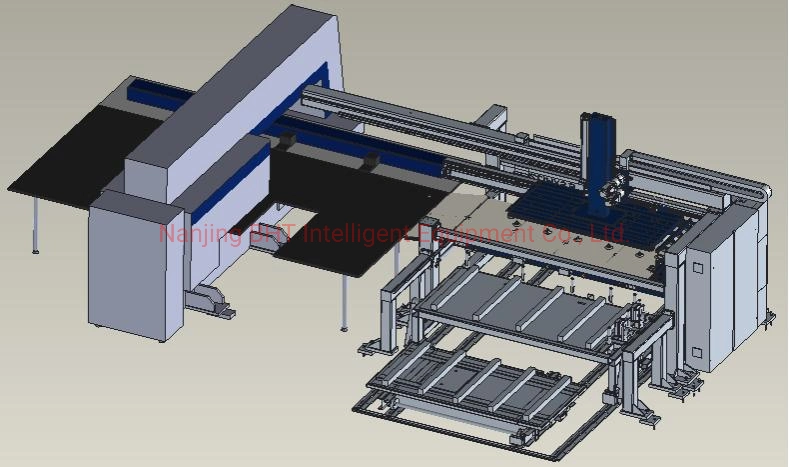

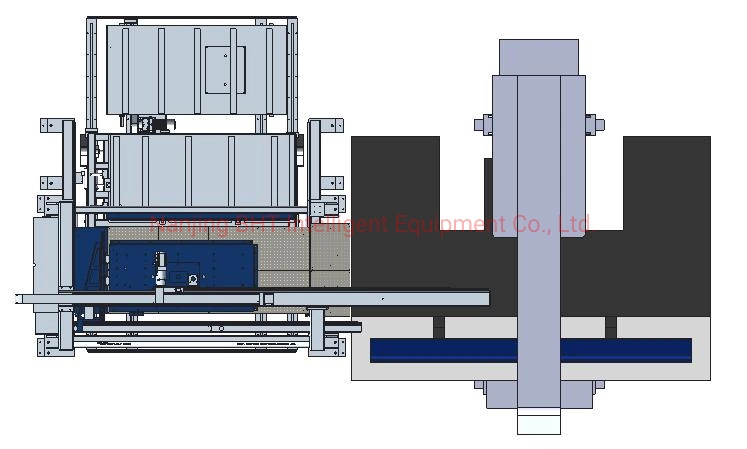

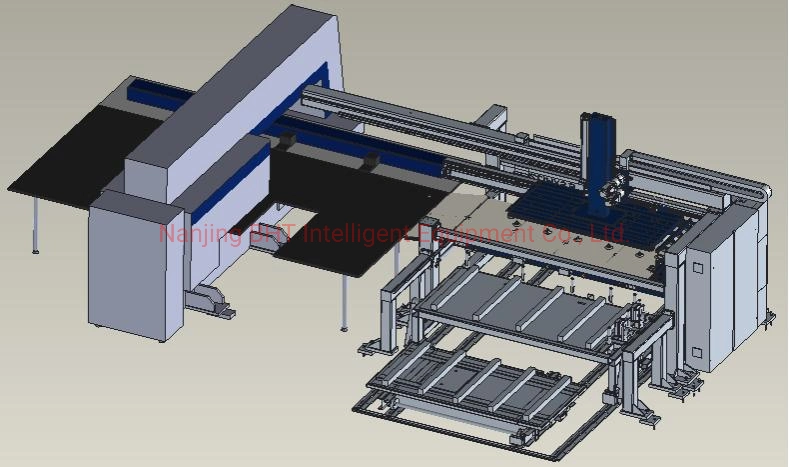

1. Summarize

The auto punching production line includes the auto loading&loading deice and turret punc.The auto loading/unloading devices locate at one sides of the turret punch.his L/UL system is to do the job of loading & unloading instead of manual work.

2.Main devices

| NO. | Description | Model | Q'ty | Note |

| | Auto L/UL device | F.SXH1530A | 1 | |

| | Turret punch | HPE-3058 | 1 |

3.System structure and technical features

3.1 Turret punch

- Sheet locating and punching

- New servo CNC turret punch,with faster speed,higher efficiency,lower noise

- CNC controller of SIEMENS 840D

- "O" type machine frame with higher rigidity

- Thick turret with better guidance,precision and longer using life

- Lower tooling easy replacement

- High speed transmission

- Auto moving clamp(Option)

| NO. | DESCRIPTION | PARAMETER | VALUE | |

| 1 | Punching pressure | 300 | KN(T) | |

| 2 | Driving type | Servo | ||

| 3 | Machine frame | "O" type | ||

| 4 | Maximum processing size | X axis | 5000(including one repositioning) | mm |

| Y axis | 1500 | mm | ||

| 5 | Maximum processing thickness | MS | 6.35 | mm |

| SS | 4 | mm | ||

| 6 | Maximum diameter with one punch | Φ88.9 | mm | |

| 7 | Punching rate | 1500 | cpm | |

| 8 | Clamp numbers | 3 | ||

| 9 | Repositioning cylinder | 2 | ||

| 10 | Turret | 40(2D) | ||

| 11 | Control axis | 5(X,Y,Z,T,C) | ||

| 12 | Turret and tooling type | Thick turret and long tooling | ||

| 13 | Standard worktable structure | Brush | ||

| 14 | Maximum moving speed of sheets | 102 | m/min | |

| 15 | Rotating speed of turret | 30 | rpm | |

| 16 | Rotating speed of tooling | 60 | rpm | |

| 17 | Punching precision | ±0.1 | mm | |

| 18 | Punching head locating precision | ±0.01 | mm | |

| 19 | Maximum supporting weight | 150 | Kg | |

| 20 | Standby power | 0.9 | Kw | |

| 21 | Average power consumption | 50 | Kw | |

| 22 | Gas pressure | 0.6 | Mpa | |

| 23 | Gas consumption | 150 | CL/ min | |

| 24 | Clamp dead area detection | YES | ||

| 25 | Clamp loosing alert device | YES | ||

| 26 | Sheet deforming detective device | YES | ||

| 27 | Dimensions | L | 5330 | mm |

| W | 5000 | mm | ||

| H | 2250 | mm | ||

| 28 | Machine weight | 16000 | kg | |

3.1.2 Main part list

| NO. | PARAMETER | BRAND |

| 1 | Controller | SIEMENS,Germany |

| 2 | Servo motor and drive | SIEMENS,Germany |

| 3 | Servo system | |

| 4 | Punching head drive | LUST,Germany |

| 5 | Timming belt and chain | TSUBAKI,Japan |

| 6 | Coupling | |

| 7 | Bearing,bearing block | NSK,Japan |

| 8 | Linear guide | THK,Japan |

| 9 | Ball screw | |

| 10 | Air resource parts | SMC,Japan \AIRTAC,TaiWan |

| 11 | Standard parts | MISUMI,Japan |

| 12 | Breaker and contactor | SIEMENS,Germany |

| 13 | Switch | Schneider,France |

| 14 | Limit switch | Contrinex,Switzerland |

| 15 | Limit switch(clamp dead zone detection) | BAULLUF,Germany |

3.1.3 This machine is made within below standards

1,GB17120-1997

2,Q/321088JW7-2012

3.2 One side loading & unloading system

- Realize the loading and unloading for whole sheet

- The semi-manufactures unloaded to be auto packed

- Auto running in 24 hours

- With edge pulling and double sheet detection function

| Maximum sheet size | 1500 mm×3000 mm |

| Minimum sheet size | 400 mm×800mm |

| Maximun sheet thickness | 4 mm |

| Minimum sheet thickness | 0.8 mm |

| Maximum stacking height | 220 mm(Containing wooden pallets) |

| Maximum stacking weight | 3000kg |

| Sheet Material | SPCC,SPHC,SGCC,SECC,SUS,AL |

| Machine total length | 8200 |

| Total width | 6100 |

| Total height | 2900 |

| Total weight | Around 7000kg |

| Cycle working time for L/UL | 20s |

3.2.1 Auto loading device

This device is to pick the sheet on the loading platform to the turret punch for processing,with below features:

1)The lifting device with air cylinder,which is to balance the weight of machine frame and sheet

2)Rack and pinion driving structure,compact structure and stable driving

3)New type edge pulling device

4)Auto stretching sucker device,can lift up the idle suckers to avoid scratching with brush worktable

3.2.2 Unloading device

Unloading device is to pick out the finished workpieces,and locate on the movable .Compact clamping structure with two sets of air cylinder.One set to controller the clamp up and down,one set is the clamp air cylinder which can clamp the sheet and pull the sheet out to the movable worktable

3.2.3 Frame and movable worktable

The features of frame and movable worktable as below:

1)Modular type structure,convenient for production and can be overall delivered

2)Easy movable worktable,driving by magnetic coupling rodless cylinder,small and lightweight with cheap cost;

3.2.4 Loading & unloading platform

1)New type interactive loading & unloading device,can work simultaneously,to realize the loading and unloading at one side.

2)Easy rail structure for stable running

|

|

|

|

|

| CNC Press Brake Machines | CNC Guillotine Shear Machines |

|  |

| CNC Fiber Laser Cutting Machine | CNC Turret Punch Machine |

|  |

| Auto Production Line | |

|  |

| BHT have exported the products to 65 countries (Germany, Sweden, Hungary, Italy, Netherlands, Spain, Portugal, Czech Republic, Lithuania, Serbia, Greece, Malta, Austria, Kosovo, Turkey, Ukraine, Albania, Estonia, Belarus, Bulgaria, Bosnia, Croatia, Romania,USA, Brazil, Argentina, Mexico, Bolivia, Colombia, Canada, Peru, Chile, Australia, New Zealand, Rwanda, Egypt, South Africa, Tanzania, Nigeria, Botswana, Mauritius, Russia, Vietnam, India, Iran, Singapore, Uzbekistan, Thailand, Sri Lanka, Bangladesh, Malaysia, Kazakhstan, Philippines, Bahrain, Pakistan, United Arab Emirates, Kuwait, Saudi Arabia, Sudan, Jordan, Oman, Qatar, Syria, Israel, Yemen) |

|