Basic Info.

Model NO.

HC-1030

Loading Method

Dynamic Load

Display

Needle

Control

Computer Control

Weight

1000-2000Kg

Power Source

AC220V

Oil Cylinder Position

Under

Transport Package

Wooden Packaging

Specification

(L)2mx(W)1.5mx(H)2.20m

Trademark

Hicensyq

Origin

China

HS Code

9024800000

Production Capacity

3000pieces/Year

Product Description

Product Overview:

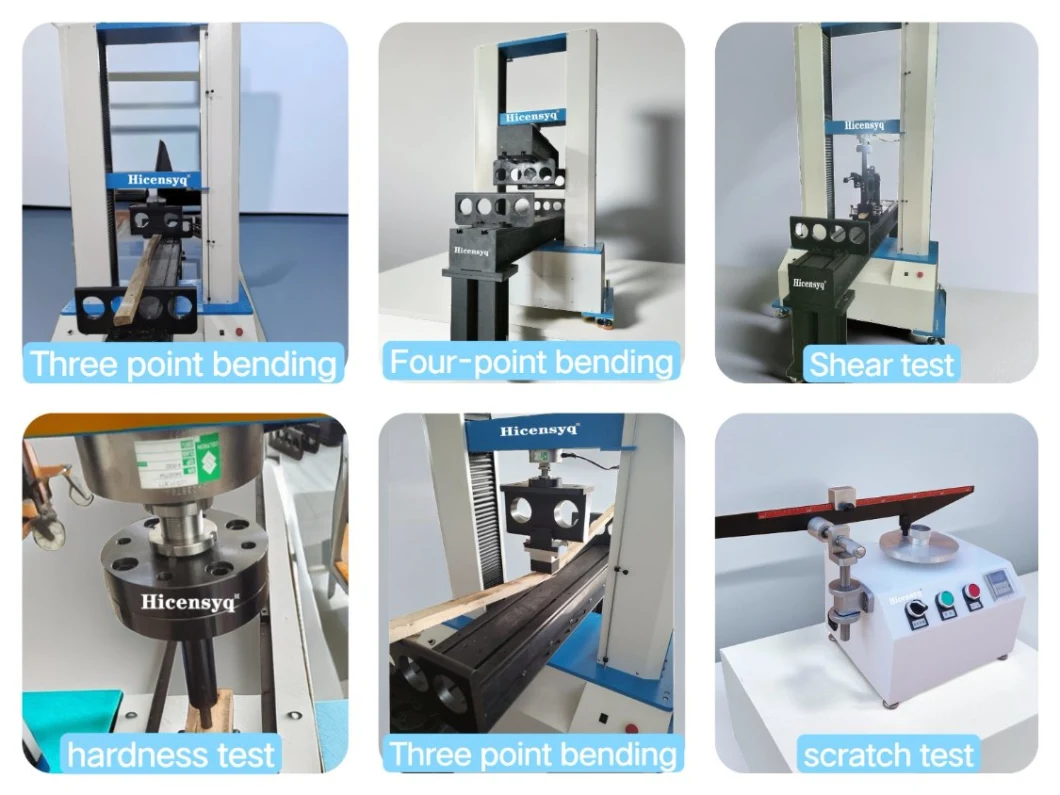

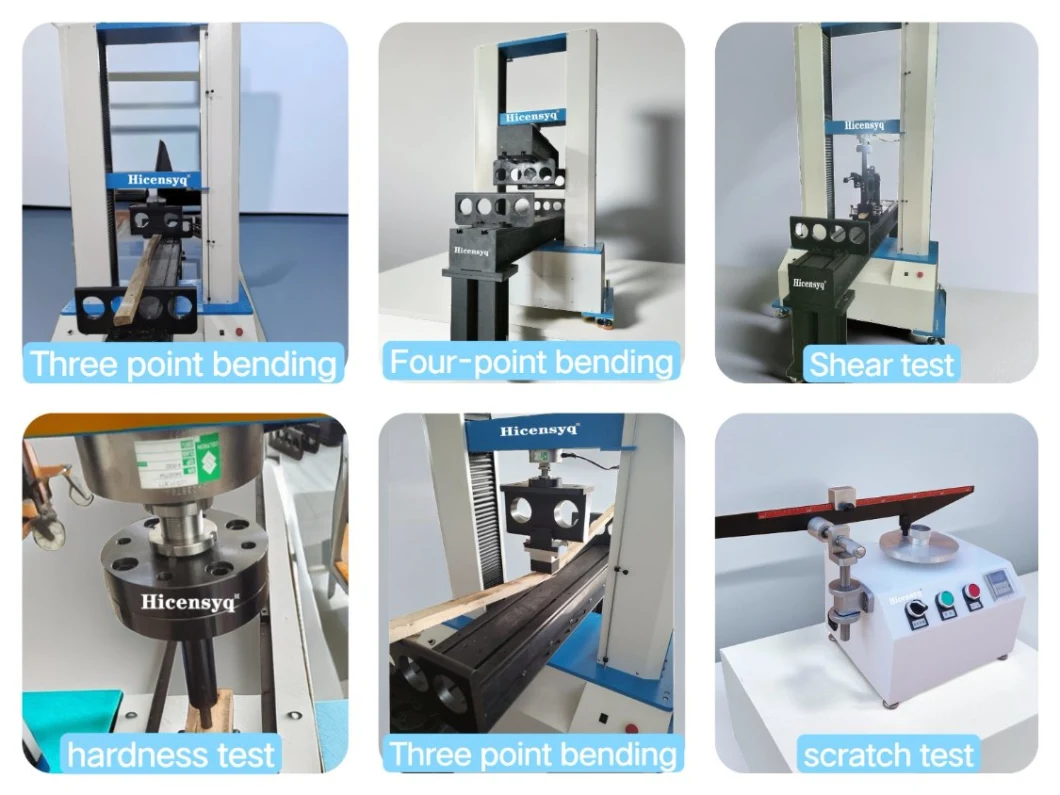

This tester is a test bench used to test samples. Take plates of corresponding sizes and different test fixtures to test the compressive strength, bending strength and hardness, peel strength, and tensile strength of the samples. The test results can be used to evaluate the quality of the samples. Test performance.

The sample performance tester system is suitable for determining the relevant mechanical properties and physical parameters of various materials under conditions such as tension, compression, bending, shearing, tearing, peeling, and puncture. It can do tension, compression, three-point bending, four-point bending, shearing, tearing, peeling and various dynamic and static cycle tests.

Device Description:

>Multiple test types: The tester can measure stress, strain, elongation, tear strength, peel strength, shear strength, yield point, modulus of elasticity, etc. Can memorize 50 sets of test data.

>Set the test speed, direction and stop mode. Once set up, testing is just a push of a button away. It can be set to return automatically after the test is completed.

>Various ports: connect printers and export data directly. Or use the software on the UTM to control the UTM, display curves or data analysis.

>Precision transmission system: servo motor drive, double ball screw, timing belt, etc.

>Protection: upper and lower limit protection, emergency stop, overload protection, over-travel protection.

Standard:

BS EN ISO 13934-1,13934-2,13937-2,13937-3,13937-4,13935-1,13935-2,BS 3320,4303.ASTM D 434,558,2256,2261,2731,3936, 4533,4964,5034,5035,5735.ISO 2062,5082,9073.4,10321,13919.

Technical Parameter:

Fixture part

If you have new requirements, please contact the technical section,Senior engineer to provide you with the most authoritative product testing scheme

Hot Products

This tester is a test bench used to test samples. Take plates of corresponding sizes and different test fixtures to test the compressive strength, bending strength and hardness, peel strength, and tensile strength of the samples. The test results can be used to evaluate the quality of the samples. Test performance.

The sample performance tester system is suitable for determining the relevant mechanical properties and physical parameters of various materials under conditions such as tension, compression, bending, shearing, tearing, peeling, and puncture. It can do tension, compression, three-point bending, four-point bending, shearing, tearing, peeling and various dynamic and static cycle tests.

Device Description:

>Multiple test types: The tester can measure stress, strain, elongation, tear strength, peel strength, shear strength, yield point, modulus of elasticity, etc. Can memorize 50 sets of test data.

>Set the test speed, direction and stop mode. Once set up, testing is just a push of a button away. It can be set to return automatically after the test is completed.

>Various ports: connect printers and export data directly. Or use the software on the UTM to control the UTM, display curves or data analysis.

>Precision transmission system: servo motor drive, double ball screw, timing belt, etc.

>Protection: upper and lower limit protection, emergency stop, overload protection, over-travel protection.

Standard:

BS EN ISO 13934-1,13934-2,13937-2,13937-3,13937-4,13935-1,13935-2,BS 3320,4303.ASTM D 434,558,2256,2261,2731,3936, 4533,4964,5034,5035,5735.ISO 2062,5082,9073.4,10321,13919.

Technical Parameter:

| Model | HC-1021D | HC-1021C3 | HC-1021 |

| Load capacity: | 100KN | 150KN | 200KN |

| Power resolution: | 1/10000 | ||

| Power accuracy: | below 0.5% | ||

| Displacement resolution: | 1/1000 | ||

| Displacement accuracy: | ≤1% | ||

| Speed range: | 0.01 ~ 200mm/min (special test speed can also be customized according to customer needs) | ||

| Walking space: | 1000mm (excluding fixtures, according to customer product requirements) | ||

| Test space: | 600mm | ||

| Main unit size: | (L)800x(W)1500x(H)2000mm | (L)800x(W)1500x(H)2200mm | (L)800x(W)1500x(H)2200mm |

| Host and fixture assembly size: | (L)2mx(W)1.5mx(H)2m | (L)2m*(W)1.5m*(H)2.2m | (L)2m*(W)1.5m*(H)2.2m |

| Host weight (approx): total weight: | 1350 kg | 1350 kg | 1350 kg |

| Power supply: | 220V 50/60Hz | ||

| PC interface: | RS232 | ||

| The instrument has a protection function to prevent the product from being cut off due to failure. | |||

Fixture part

HC-1021D1-1 Three-point bending fixture1

| Three-point bending fixture 1 | |

| Model | HC-1021D1-1 |

| size | 500mm W x 2000mm L |

| Upper pressure head diameter | 50.8mm |

HC-1021D1-2Three-point bending fixture 2

| Three-point bending fixture 2 | |

| Model | HC-1021D1-2 |

| Compression surface size | 100mmX76mm |

| hardness | 90 |

HC-1021D2 shear test fixture

| shear test fixture | |

| Model | HC-1021D2 |

| Thickness | 20-50mm |

| Width | 50mm |

| Length | 200--320mm |

| The material of the cutting edge needs heat treatment, and it must not be chamfered, and a lifting handle is added. | |

HC-1021D3 Hardness test flextural

| Hardness testing fixture | |

| Model | HC-1021D3 |

| Shaft diameter | 12.7mm |

| shape | round head |

| 1000lbf fixed pressure. | |

| Hardness test fixture, material through heat treatment. | |

HC-1021D4 Four point bending fixture

| Four point bending fixture | |

| Model | HC-1021D4 |

| Bottom Beam Length | 2m |

| Upper Beam Length | 1m |

| Pivot Width | 500mm |

| Heat treatment of four indenters | |

If you have new requirements, please contact the technical section,Senior engineer to provide you with the most authoritative product testing scheme

Hot Products

| Q1:Is your company a trading one or a factory? |

| A1:Our factory produces goods directly. We have focused on the development and manufacturing of physical and environmental testing equipments for 18 years,besides,we have export experience of six years. |

| Q2:What about the quality of services and products? |

| A2:Berore shipping and delivering the goods,each product must be tested and tested for 100% . |

| Products using training: we would provide a training video of each product in order to show you how to install and operate. |

| All products meet the standsrds of ISO, ASTM, AATCC, BS, EN, DIN, JIS, GB and other requirements. |

| Q3:How long is the delivery time? |

| A3:Usually about 15 to 25 days.If we have stock, we can arrange the shipment within 3 days. |

| Kindly note that our producing and delivery time depend on specific item and the number of it. |

| except for the special customization. |

| Q4:Distance transportation, the packaging is strong enough? |

| A4:Packing: the first layer uses bubble film ,and the second layer uses vacuum film.We take away the air so as to make a vacuum environment after packing,which can avoid the problem of rust on the rough sea,and the outer packing using standard wooden cases. |

| Q5: What is the mode of payment? |

| A5: Generally we use telegraphic transfer,inculding 50% deposit and 50% before shipment.Other payment methods can be negotiated. |

| Q7:How warranties and after-sales services? |

| A7:Our products have 18-month warranty. |

| Life-long free technical support, be video through email.Besides, we can help you to repair your problem controller , even it's not from our factory Produce. |

| What you need to do is to send us the controller. |

| Outside the warranty period, professional after-sales service team will provide the perfect technical support, and help customers to solve problems when using our products, deal with guest problems and complaints, and in a professional and timely. |