Basic Info.

Model NO.

DIN

Surface Treatment

Tin Ticn Tiain Most P-Wear

OEM

Non-Standard Customization

Application1

Stamping Dies, Medical Equipment, Automobiles

Mould Life

200000-500000shots

Lead Time

3-20 Days

Surface Finish

9 -14 Uin Ra

Hardness

35HRC-85HRC

Heat-Treat Process

Vacuum Nitrided Hot Treatment Salt Bath Heat-Treat

Transport Package

Customized Bags and Boxes

Specification

0.1mm-50mm

Trademark

cungang

Origin

Zhejiang

Production Capacity

500000 Pieces Per Year

Product Description

| Product Name | punch pin die |

| Materials | 45#,S50C,CR12/CR12MOV,SKD11,DC53,SKH-9,SKH-51,SKH-55, ASP23, ASP30, ASP60, CD650, 2210, YG15, YG8, V30, KD20 etc |

| Standard | Standard Hardware/ Plastic Parts as per MISUMI, DME, HASCO, FIBRO, CUMSA, STRACK, DAYTON NON-Standard parts can be designed or made customized |

| Hardness | HRC58-60,HRC64-66,HRC88-90 |

| Tolerance | ±0.001mm |

| Heat treatment method | High frequency quenching, vacuum heat treatment, quenching and tempering treatment |

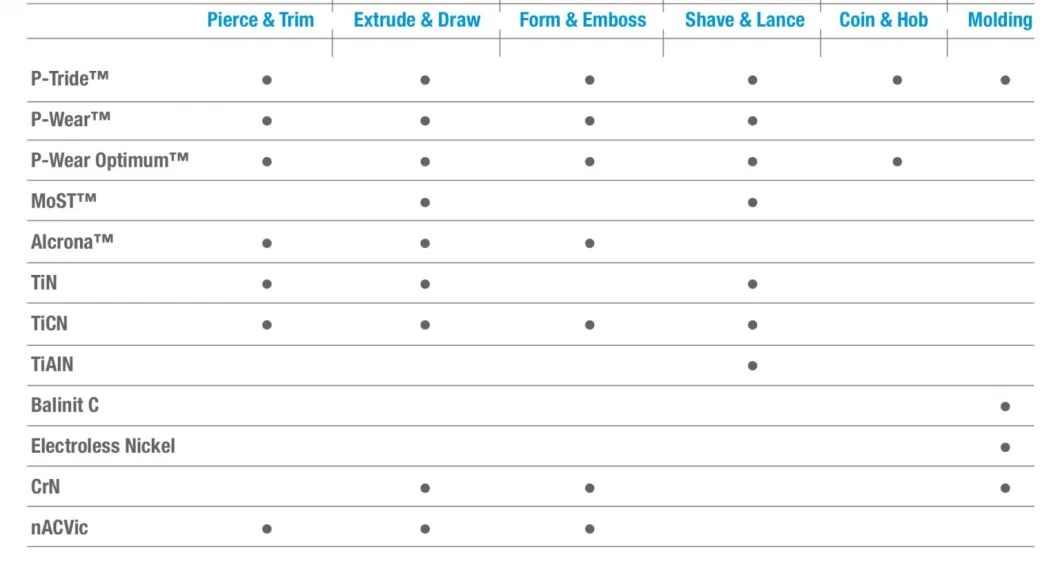

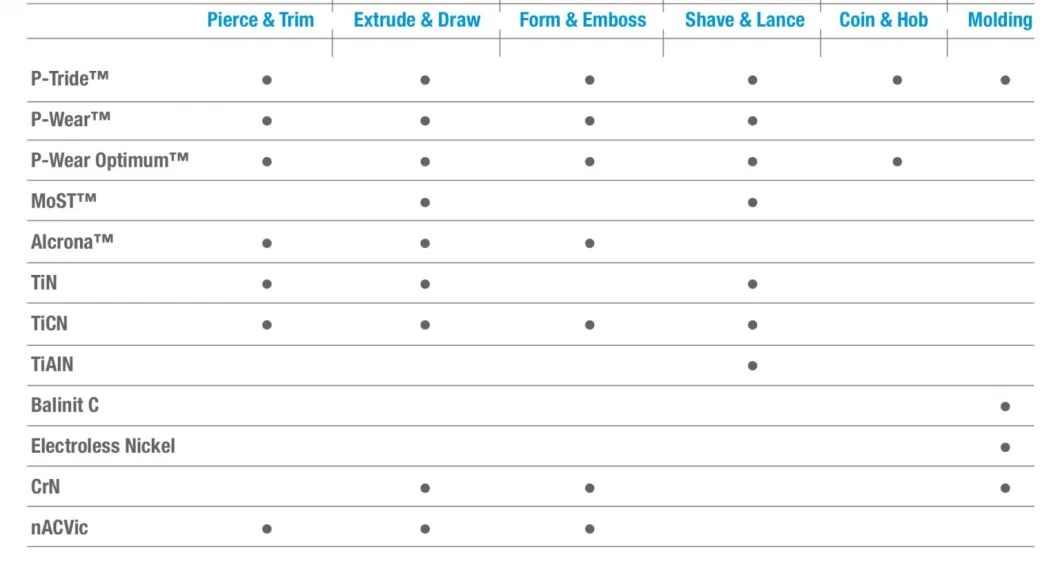

| Surface treatment method | Black-plated titanium | Yellow-plated titanium | Chrome-plated | Nickel-plated | P-Tride™ | P-Wear™ | P-Wear Extreme™ | MoST™ | Alcrona™ | TiN | TiCN | TiAIN Balinit C | Electroless Nickel | CrN |

| Lead Time | Sampling: 3-5 workdays,Normal making: 5-10 workdays,Complex design/making: 10-18 workdays |

Wear resistant surface treatments offer great benefit to stamping tools when applied appropriately. While there are many good surface treatments and processes to choose from, Physical Vapor Deposition (PVD) coatings are ideally suited and typically the best option to use on precision slip and press fit punch components.

Selecting the right surface treatment and substrate tool steel combination is critical for achieving optimum tool life. PVD coatings provide excellent abrasion and galling resistance while maintaining the integrity of many substrate tool steels. These coatings work best when applied to high speed tool steels such as M-2, PM-M4, and T-15. A few select cold work tool steel grades can also be PVD coated successfully as long as they maintain at least a 60 HRC when tempered at or above 1,000 degrees Fahrenheit.

It is important to note that the PVD process is a line of sight process, which may limit the ability to coat interior contours and features. For these applications, nitriding, which case-hardens all exposed surfaces, is recommended.

Selecting the right surface treatment and substrate tool steel combination is critical for achieving optimum tool life. PVD coatings provide excellent abrasion and galling resistance while maintaining the integrity of many substrate tool steels. These coatings work best when applied to high speed tool steels such as M-2, PM-M4, and T-15. A few select cold work tool steel grades can also be PVD coated successfully as long as they maintain at least a 60 HRC when tempered at or above 1,000 degrees Fahrenheit.

It is important to note that the PVD process is a line of sight process, which may limit the ability to coat interior contours and features. For these applications, nitriding, which case-hardens all exposed surfaces, is recommended.

Below is a list of standard surface treatments offered.

Additional coatings are available upon request.