Basic Info.

Working Size

1500X3000mm ;2000X4000 mm

Work Table

Saw Tooth Work Table

Position Speed

2000 mm/Min

Locating Precisioon

<0.01 mm

Transmit System

Dual Rack & Pinion Type

Laser Beam Quality

<0.373mrad

Power Supply

AC 380V/50Hz or Depend User′s Requirement

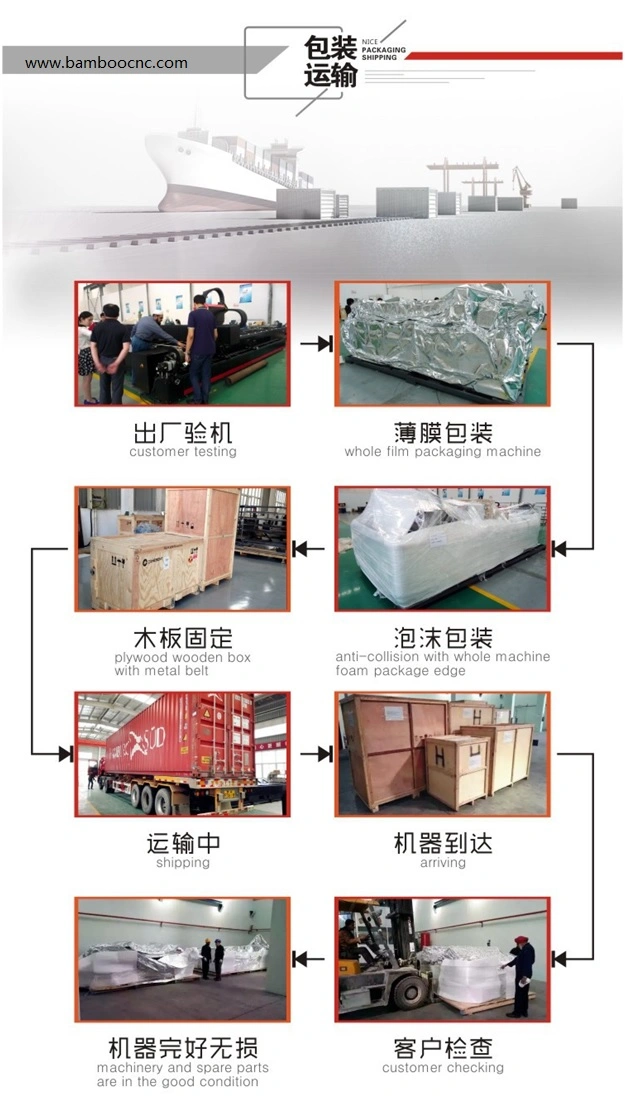

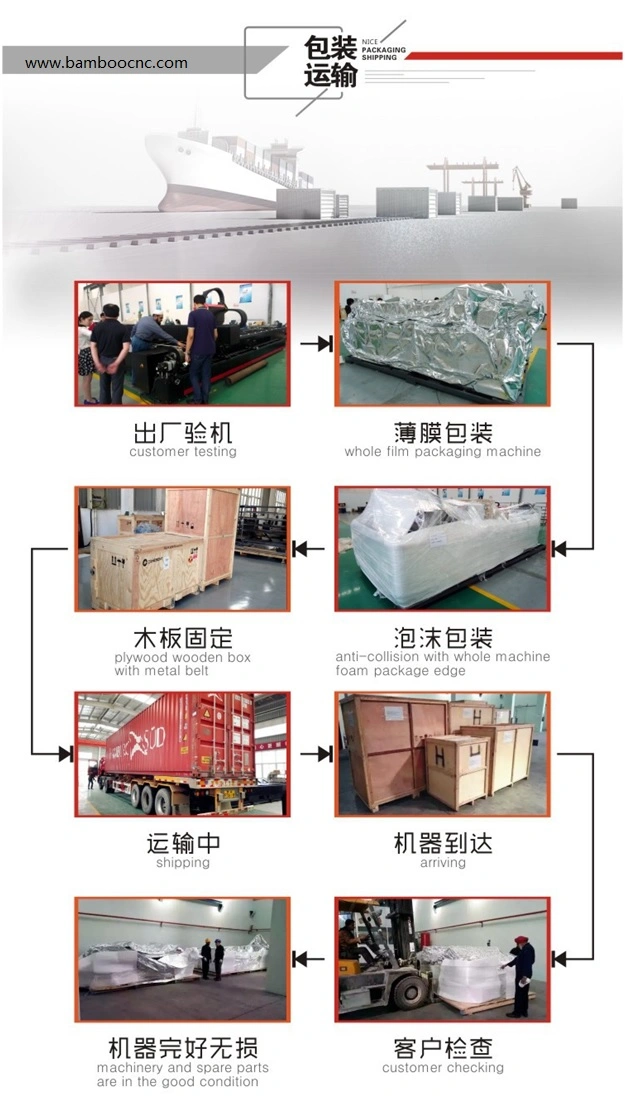

Transport Package

Wooden Packing

Specification

1500X3000

Trademark

BAMBEOCNC

Origin

China

HS Code

84623990

Production Capacity

30sets/Per Month

Product Description

Single fiber laser cutting machine

Main Features:

1. Low maintenance --- it's transmited by Fiber cable, no need reflecting mirrors, no need to adjust the light route;

Bamboocnc's Fiber Laser cutting is among the largest application for lasers in material processing.

Fiber laser technology allows for small beam diameter therefore decreasing kerf width, decreasing heat penetration and increasing throughput.

Also, the power consumption of Fiber laser is very low, no need maintenance,

it's suits for batch production, high requirements with cutting quality and cutting speed.

Compared with other laser source.

Fiber laser technology allows for small beam diameter therefore decreasing kerf width, decreasing heat penetration and increasing throughput.

Also, the power consumption of Fiber laser is very low, no need maintenance,

it's suits for batch production, high requirements with cutting quality and cutting speed.

Compared with other laser source.

Main Features:

1. Low maintenance --- it's transmited by Fiber cable, no need reflecting mirrors, no need to adjust the light route;

2.Low consumption---The power is more than 30% lower than the ordinary cutting machine.

3.Maintenance-free---For the fiber laser cutter, the reflect lens are no needed. It will help to save a lot of time when optical path is adjusted. The laser generator with longer lifetime which no need maintenance during usage.

4.Environment friendly--Laser cutting will not creates any gases for the special cutting technology for steel sheet.

5.Low power consumption--- Energy saving and environmental friendly, lowest power consumption as

the highest photoelectric conversion with Fiber source. Only 20%-30% consumption compared with other laser

cutting system.

6.Low gas consumption--- no need mixed gas for cutting, high pressure air can also cutting steel.

7. Maximum simultaneous positioning speed: 160m/min.

8 Precision: + - 0.05 mm.

9. Energy efficiency: greatly reduced power consumption.

10. Excellent cutting quality for fine thic kness and medium thickness sheet metals.

Details Images:

The main technical :

Applicable materials: 5.Low power consumption--- Energy saving and environmental friendly, lowest power consumption as

the highest photoelectric conversion with Fiber source. Only 20%-30% consumption compared with other laser

cutting system.

6.Low gas consumption--- no need mixed gas for cutting, high pressure air can also cutting steel.

7. Maximum simultaneous positioning speed: 160m/min.

8 Precision: + - 0.05 mm.

9. Energy efficiency: greatly reduced power consumption.

10. Excellent cutting quality for fine thic kness and medium thickness sheet metals.

Details Images:

The main technical :

| Laser power | 1500W |

| Laser Generator | Raycus |

| Laser generator working mode | Continuous/Modulation |

| Laser Cutting Head | Raytools compact USA Lasermech |

| Work size | 3000mm x 1500mm |

| X axle stroke | 3050mm |

| Yaxle stroke | 1530mm |

| Z axle stroke | 120mm |

| CNC control | PMAC/Industrial control computer with cutting software |

| Focus Lens | Worthing(WSX) |

| X,Y Axis Position accuracy | ±0.03mm |

| X,Y Axis Repeat position accuracy | ±0.02mm |

| X, Y Axis max linkage speed | 110m/min |

| Max Acceleration | 1G |

| Laser wavelength | 1070 mm -1080 nm |

| Cooling | Water cooling |

| Dimension | 4200x2100x1000 mm |

| Format supported | AI, PLT, DXF, etc |

| Machine weight | 4900KG |

| Lubrication | Automatic lubrication |

| Auxiliary Gas | 3 separate gas routes ( unique design) |

| Laser cutting nozzle | Dynamic focus following |

| Electronics and control | Controlling unit |

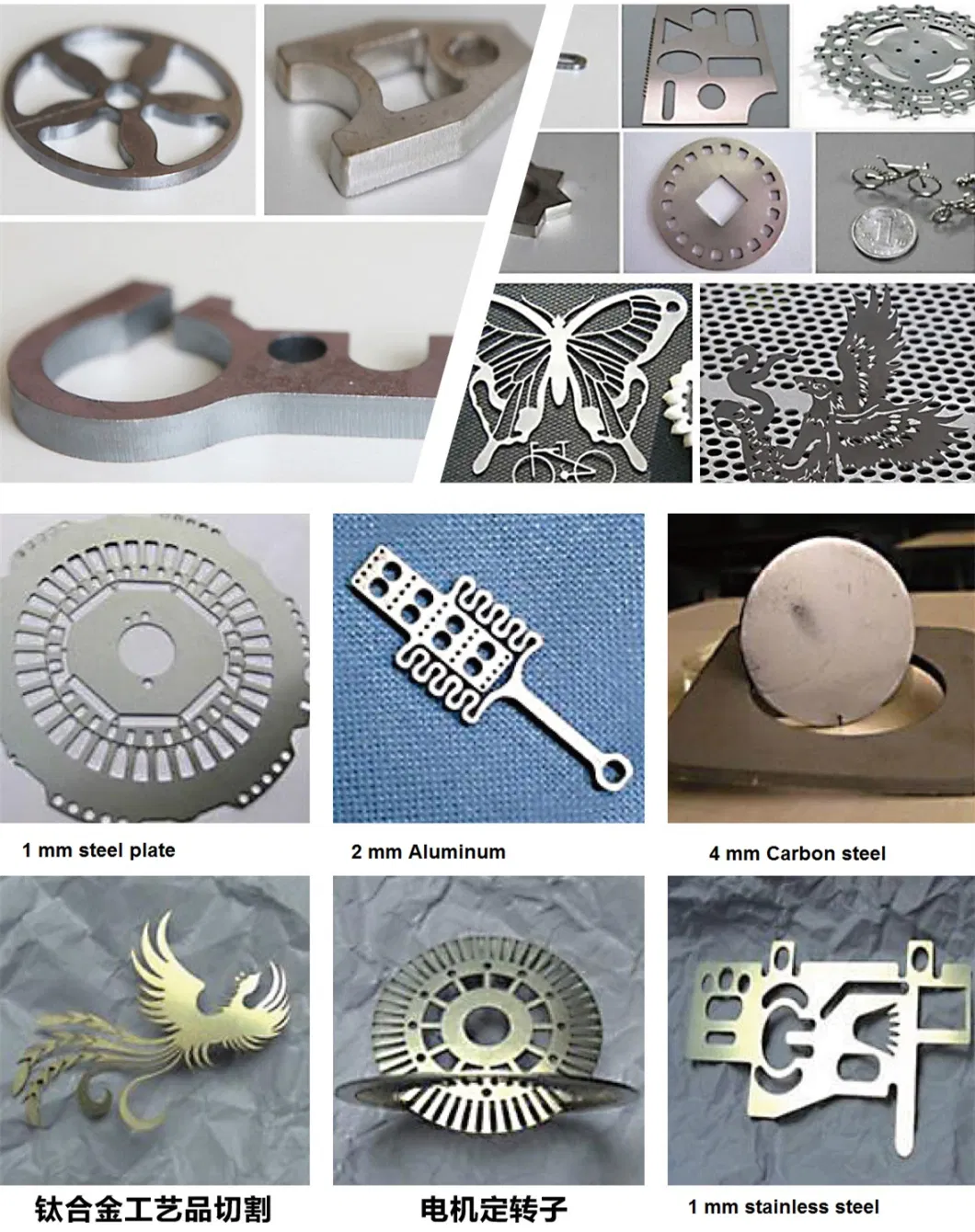

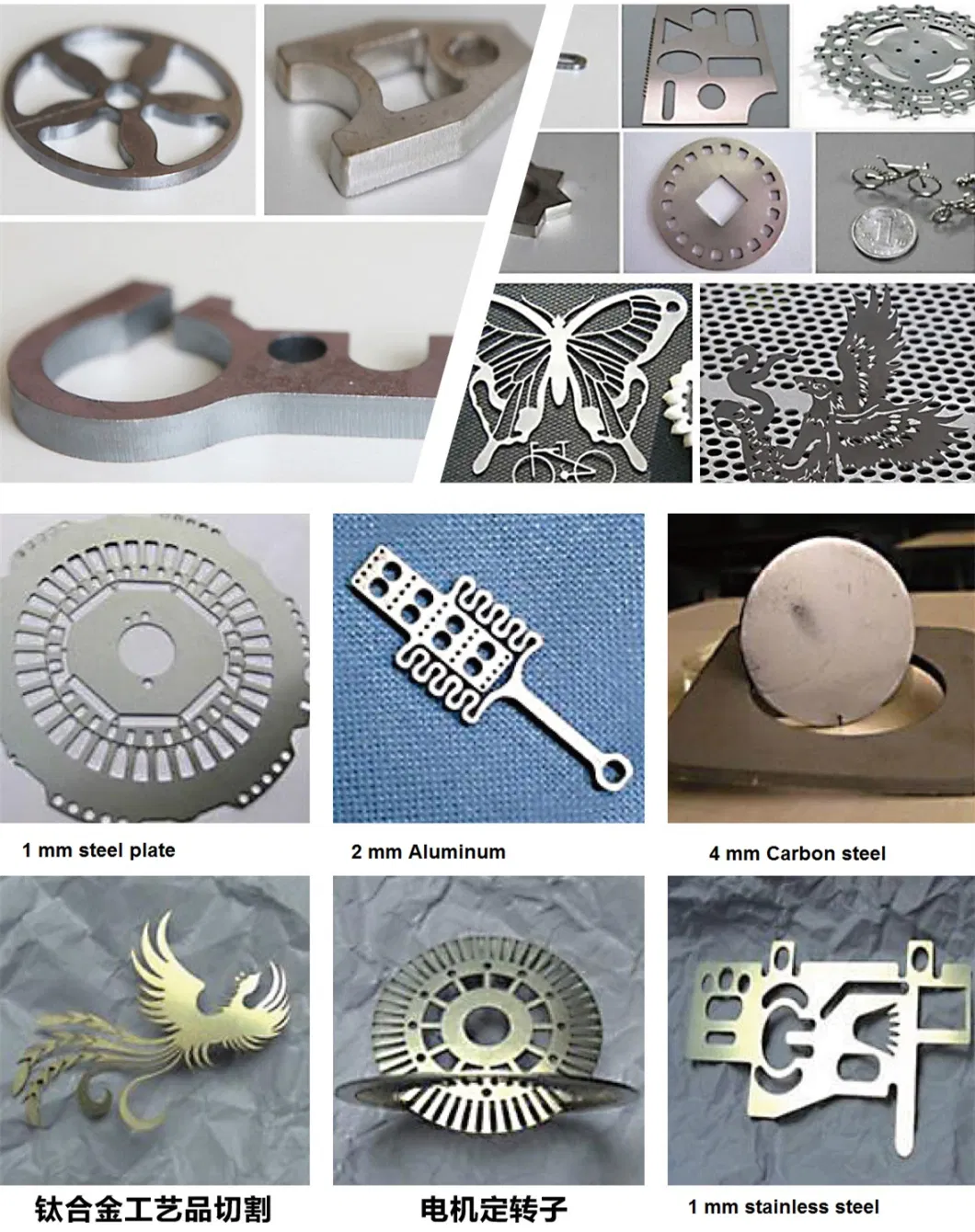

Applied in sheet metal processing, aviation, spaceflight, electronics, electrical appliances, subway parts, automobile, machinery, precision components, ships, metallurgical equipment, elevator, household appliances, gifts and crafts, tool processing, adornment, advertising, metal foreign processing various manufacturing processing industries.

Mainly used for cutting carbon steel, silicon steel, stainless steel, aluminum alloy, titanium alloy, galvanized steel sheet, pickling board, aluminum zinc plate, copper and many kinds of metal materials cutting and so on.

The cutting product :

The packing :Mainly used for cutting carbon steel, silicon steel, stainless steel, aluminum alloy, titanium alloy, galvanized steel sheet, pickling board, aluminum zinc plate, copper and many kinds of metal materials cutting and so on.

The cutting product :