- Overview

- CONFIGURATION

Basic Info.

Model NO.

CKD-FCLD-500/1000/1500/2000

Structure Type

Full Sealing

Laser Classification

Solid Laser

Laser Technology

Laser Vapor Cutting

Shipping Time

20-25 Work Days After Payment for Standard Type

Payment Term

100% T/T in Advance

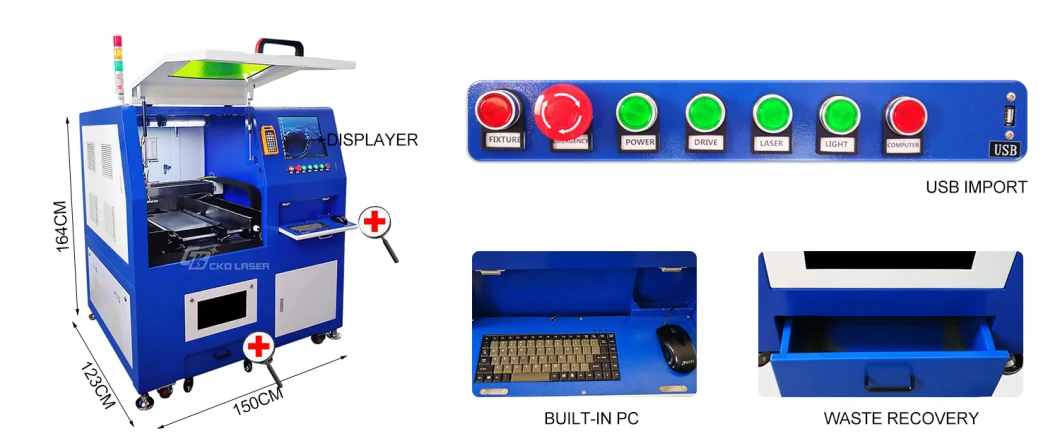

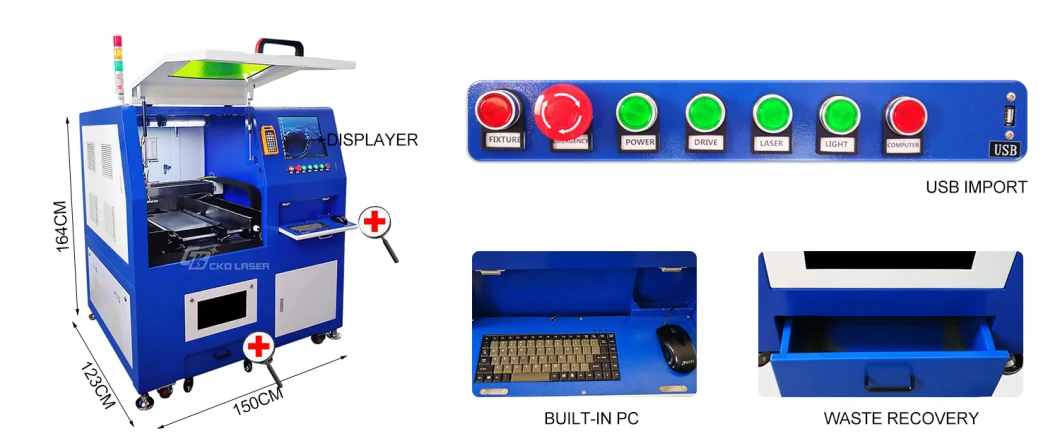

Machine Demension

1500*1230*1640mm

Laser Power

Optional: 1000/1500W

Gross Weight

1230-1250 Kg, Depends on Laser Power

Transport Package

Wooden Box

Specification

CE passed, Europe/ Asia/ America Standard

Trademark

CKD LASER

Origin

Shenzhen, China

HS Code

8461500090

Production Capacity

20 Sets/Month

Product Description

CKD-FCLD adopts top configuration and every part is the top-quality brands. It is mainly used for cutting sheet metal in high precision. CKD-FCLD series has 500W,1000W, 1500W and 2000W types, used for accurate smaller work piece producing.

APPLICABLE MATERIAL

stainless steel, carbon steel, alloy steel, aluminum, iron, copper, and other metal.

APPLICABLE INDUSTRIES

Glasses frames, metal crafts, decoration, mechanical parts, electrical instrumentation, and so on.

In the face of a wide range of processing materials, flexible processing of the shape, CKD-FCLD laser cutting machine can be better qualified for complex processing requirements, high speed, high precision, high quality to meet the automotive, aerospace, health care, plastics, electrical and electronics, textiles and other industry application needs.

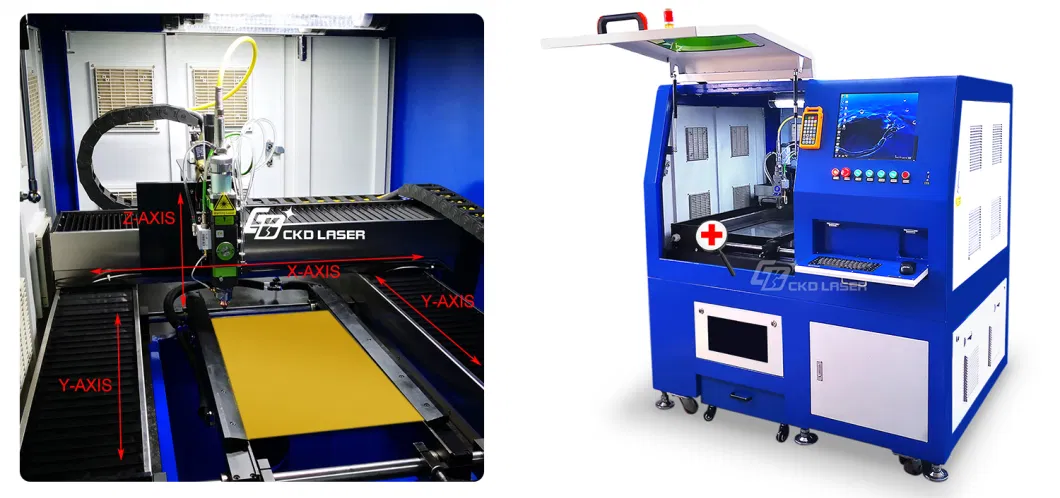

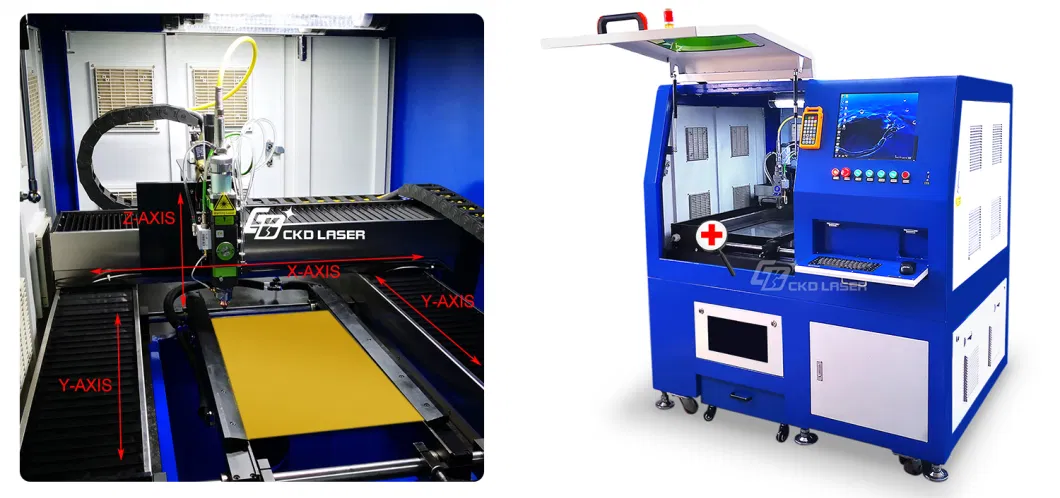

Cutting bed: X=400mm, Y=500mm, Z=50mm

CKD-FCLD is a built-in waste recycling device and built-in computer.

The built-in alarm device of CKD-FCLD effectively protects the safety of the and machine, all errors will be recorded in the computer for easy viewing and maintenance.

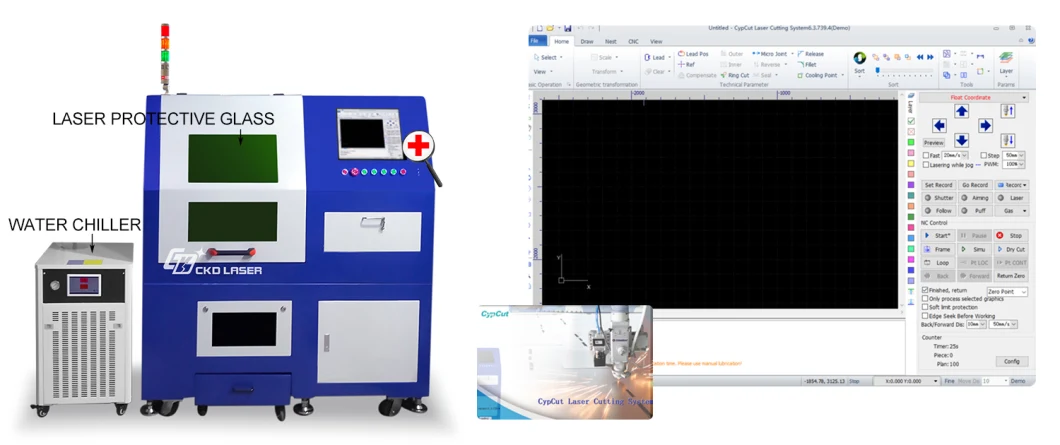

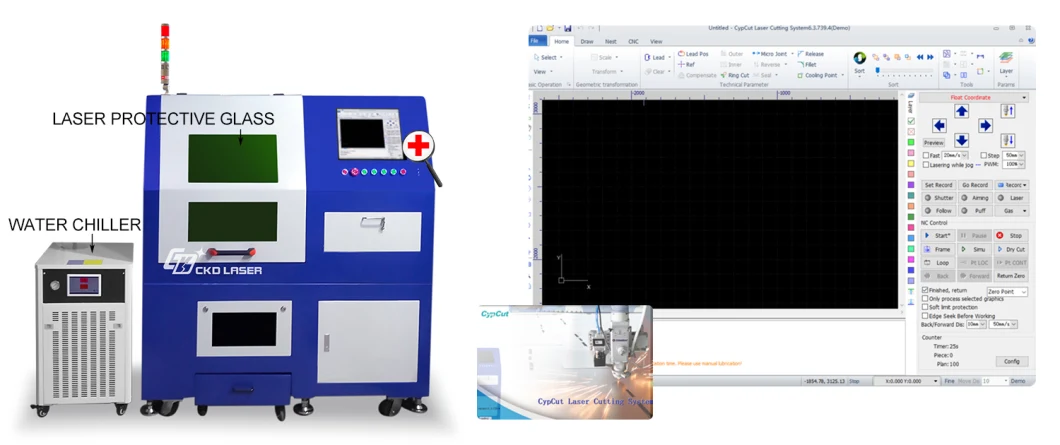

Use professional laser protective glass OD4+, thermostatic industrial water chiller, and powerful CypCut cutting software in kinds of languages.

CUTTING PARAMETER

Please choose laser power according to yout application , or consult us with yout company infomation

APPLICABLE MATERIAL

stainless steel, carbon steel, alloy steel, aluminum, iron, copper, and other metal.

APPLICABLE INDUSTRIES

Glasses frames, metal crafts, decoration, mechanical parts, electrical instrumentation, and so on.

In the face of a wide range of processing materials, flexible processing of the shape, CKD-FCLD laser cutting machine can be better qualified for complex processing requirements, high speed, high precision, high quality to meet the automotive, aerospace, health care, plastics, electrical and electronics, textiles and other industry application needs.

Cutting bed: X=400mm, Y=500mm, Z=50mm

CKD-FCLD is a built-in waste recycling device and built-in computer.

The built-in alarm device of CKD-FCLD effectively protects the safety of the and machine, all errors will be recorded in the computer for easy viewing and maintenance.

Use professional laser protective glass OD4+, thermostatic industrial water chiller, and powerful CypCut cutting software in kinds of languages.

| Parameter | Unit | Data |

| Laser wavelength | nm | 1070-1080 |

| Cutting area | mm | 500*400 |

| Z-axis path | mm | 50 |

| Machine tolerance | mm/m | ±0.05 |

| Repetitive tolerances | mm | 0.03 |

| X, Y-axis location accuracy | mm | ≤±0.01 |

| X, Y-axis repeat location accuracy | mm | ≤±0.01 |

| Max cutting speed | m/min | ≤30 |

| Requisite voltage | V | 220 |

| Maximum voltage tolerance | +6%/-10% |

CUTTING PARAMETER

| Type | Power | Material | Thickness (mm) | Cutting gas | Cutting speed (m/min) | Gas pressure(MPa) |

| CKD-FCLD-500 | 500W | carbon steel | 2 | O2 | 5.00 | 0.50 |

| 3 | O2 | 2.00 | 0.50 | |||

| 6 | O2 | 0.90 | 0.08 | |||

| stainless steel | 1 | N2 | 12.00 | 2.00 | ||

| 2 | N2 | 2.50 | 2.00 | |||

| CKD-FCLD-1000 | 1000W | carbon steel | 2 | O2 | 6.00 | 0.50 |

| 3 | O2 | 2.80 | 0.05 | |||

| 6 | O2 | 1.30 | 0.07 | |||

| 8 | O2 | 1.10 | 0.07 | |||

| 10 | O2 | 0.85 | 0.08 | |||

| stainless steel | 1 | N2 | 23.00 | 2.00 | ||

| 2 | N2 | 7.00 | 2.00 | |||

| 3 | N2 | 2.80 | 2.00 | |||

| 4 | N2 | 1.50 | 2.00 | |||

| aluminum | 1 | N2 | 20.00 | 2.00 | ||

| 2 | N2 | 3.00 | 2.00 | |||

| 3 | N2 | 1.00 | 2.00 | |||

| brass | 1 | N2 | 20.00 | 2.00 | ||

| 2 | N2 | 3.50 | 2.00 | |||

| 3 | N2 | 1.20 | 2.00 | |||

| copper | 1 | O2 | 6.00 | 0.50 | ||

| 2 | O2 | 0.80 | 0.50 | |||

| CKD-FCLD-1500 | 1500W | carbon steel | 2 | O2 | 7.00 | 0.50 |

| 3 | O2 | 3.50 | 0.05 | |||

| 6 | O2 | 2.20 | 0.06 | |||

| 6 | O2 | 1.70 | 0.07 | |||

| 8 | O2 | 1.30 | 0.07 | |||

| 10 | O2 | 1.10 | 0.07 | |||

| 12 | O2 | 0.90 | 0.07 | |||

| 14 | O2 | 0.73 | 0.07 | |||

| 16 | O2 | 0.63 | 0.07 | |||

| stainless steel | 1 | N2 | 35.00 | 2.00 | ||

| 2 | N2 | 11.00 | 2.00 | |||

| 3 | N2 | 4.50 | 2.00 | |||

| 4 | N2 | 2.50 | 2.00 | |||

| 5 | N2 | 1.50 | 2.00 | |||

| 6 | N2 | 0.90 | 2.00 | |||

| aluminum | 1 | N2 | 30.00 | 2.00 | ||

| 2 | N2 | 7.00 | 2.00 | |||

| 3 | N2 | 3.50 | 2.00 | |||

| 4 | N2 | 1.50 | 2.00 | |||

| brass | 1 | N2 | 30.00 | 2.00 | ||

| 2 | N2 | 7.00 | 2.00 | |||

| 3 | N2 | 2.80 | 2.00 | |||

| 4 | N2 | 1.00 | 2.00 | |||

| copper | 1 | O2 | 13.00 | 0.50 | ||

| 2 | O2 | 2.50 | 0.50 | |||

| 3 | O2 | 1.50 | 0.60 | |||

| 4 | O2 | 0.60 | 0.60 | |||

| CKD-FCLD-2000 | 2000W | carbon steel | 3 | O2 | 4.20 | 0.05 |

| 6 | O2 | 2.60 | 0.08 | |||

| 8 | O2 | 1.50 | 0.08 | |||

| 10 | O2 | 1.30 | 0.09 | |||

| 12 | O2 | 1.00 | 0.10 | |||

| 14 | O2 | 0.80 | 0.10 | |||

| 16 | O2 | 0.70 | 0.11 | |||

| 18 | O2 | 0.65 | 0.12 | |||

| 20 | O2 | 0.60 | 0.13 | |||

| 22 | O2 | 0.55 | 0.14 | |||

| stainless steel | 1 | N2 | 45.00 | 2.00 | ||

| 2 | N2 | 13.00 | 2.00 | |||

| 3 | N2 | 6.00 | 2.00 | |||

| 4 | N2 | 4.50 | 2.00 | |||

| 5 | N2 | 2.50 | 2.00 | |||

| 6 | N2 | 1.50 | 2.00 | |||

| 8 | N2 | 0.70 | 2.00 | |||

| aluminum | 1 | N2 | 30.00 | 2.00 | ||

| 2 | N2 | 12.00 | 2.00 | |||

| 3 | N2 | 5.00 | 2.00 | |||

| 4 | N2 | 3.00 | 2.00 | |||

| 5 | N2 | 1.50 | 2.00 | |||

| 6 | N2 | 1.00 | 2.00 | |||

| brass | 1 | N2 | 35.00 | 2.00 | ||

| 2 | N2 | 12.00 | 2.00 | |||

| 3 | N2 | 4.50 | 2.00 | |||

| 4 | N2 | 2.50 | 2.00 | |||

| 5 | N2 | 1.50 | 2.00 | |||

| 6 | N2 | 0.80 | 2.00 | |||

| copper | 1 | O2 | 25.00 | 0.50 | ||

| 2 | O2 | 6.00 | 0.50 | |||

| 3 | O2 | 2.50 | 0.60 | |||

| 4 | O2 | 0.80 | 0.60 | |||

| 5 | O2 | 0.40 | 0.60 |

Please choose laser power according to yout application , or consult us with yout company infomation