Basic Info.

Model NO.

FL-P6060

Laser Classification

Fiber Laser

Laser Technology

Laser Cutting

Laser Power

1000W-120000W Optional

Working Area

6000*2000mm

Laser Source

Max/Raycus/Ipg Optional

Laser Head

Raytools/Ospri/Wsx/Precitec Optional

CNC Control System

Cypcut

Voltage

380V 50/60Hz

Max Moving Speed

80000mm/Min

Maximum Accelerated Speed

1.0g

Transport Package

Standard Wooden Case

Specification

3015

Trademark

FORTUNE LASER

Origin

China

HS Code

8456110090

Product Description

6060 Small area precision Industrial Metal Optical Fiber Laser Cutting Machine

The price above is only for your reference. Prices can be different for different machine configurations, please contact us for the latest quotation.

Machine Characters

Safety structure : Less occupation, good for small workshop;Easy operation : The leading Cypcut cutting system, easy to use;

Anti-corrosion wear : Free maintenance of transmission parts, corrosive material cutting is available;

Stable and durable : Marble machine tool, less distortion, high stability, anti-shock while high speed working;

Precision cutting : Precision cutting comes from Switzerland RAYTOOLS laser cutting head;

Fiber Laser: Adopted with top brand fiber lasers China made with good quality and stability;

Precision motion mechanism : High quality driving system can improve cutting accuracy and efficiency.

| Machine configuration | |

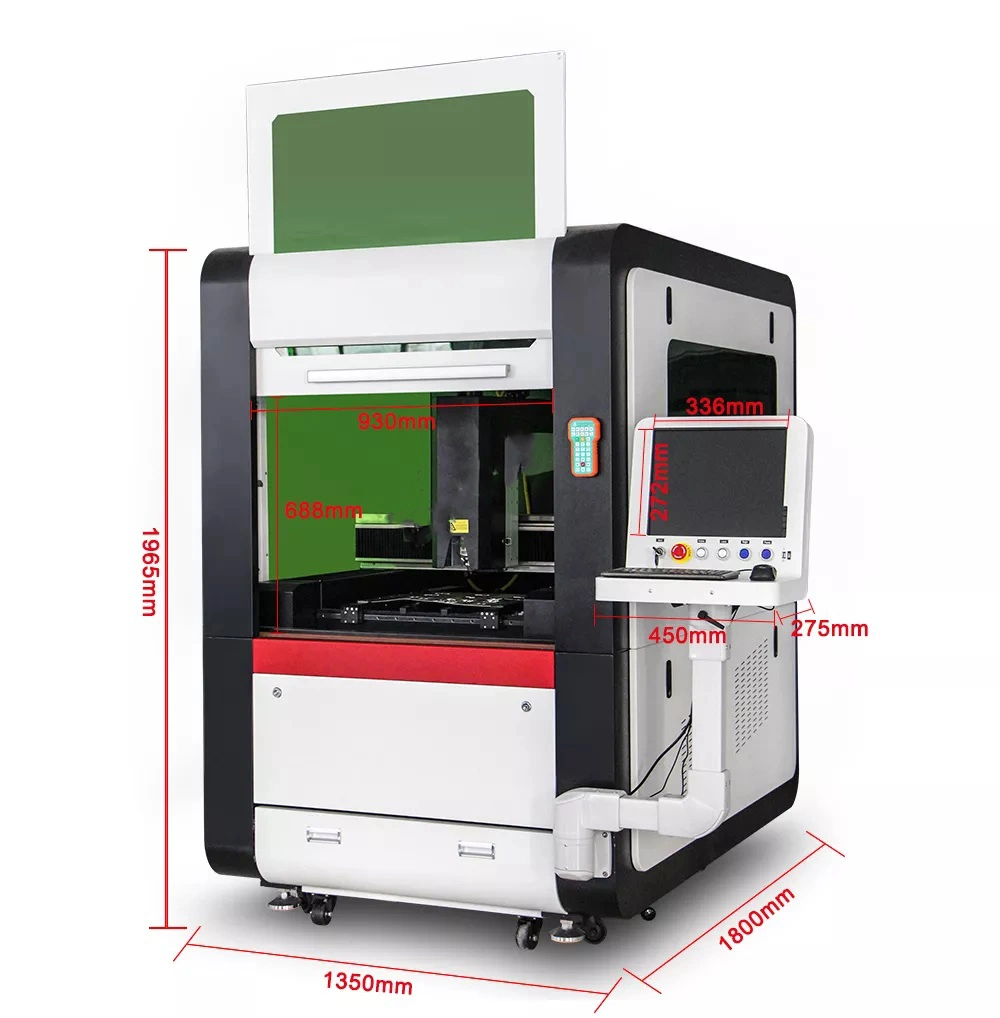

| Model | Precision Fiber Laser Cutting Machine FL-P Series |

| Working Area | 600mm*600mm |

| Laser source | 1000W-12000W |

| CNC Cutting System | Cypcut operating system |

| Laser head | OSPRI/Raytools/PRECITEC |

| Machine bed | Fortune Laser |

| X/Y axis gear rack | Fortune Laser |

| Precision linear guide | ROUST |

| Motor Drive | Japan Yaskawa Servo motor (X750W/Y750W/Z400W) |

| Electronic components | France Schnei -der |

| Reducer system | PHILANDE |

| Pneumatic components | Japan SMC |

| Machine bed accessories | Fortune Laser |

| Water chiller | Hanli |

| Waste recycling equipment | Fortune Laser |

Note: This machine configuration is only for your reference, many other brands for each part of the machines are optional based on your requirements and your budget. Please feel free to contact us for more details.

Machine Parts

Strong machine lathed bed

The lathed bed is after aging treatment: 1600ºChigh temperature heat treatment, 24 hours with furnace cooling and precise co2 protection welding, which ensures along-term stability and no deformation.

The lathed bed is after aging treatment: 1600ºChigh temperature heat treatment, 24 hours with furnace cooling and precise co2 protection welding, which ensures along-term stability and no deformation.

Aerospace-grade aluminum gantry

Aerospace-grade aluminum light quality, high speed, good dynamic response, fast acceleration.

Beam as a whole by the finite element analysis optimization of high rigidity, lightweight design, and durable.

Aerospace-grade aluminum light quality, high speed, good dynamic response, fast acceleration.

Beam as a whole by the finite element analysis optimization of high rigidity, lightweight design, and durable.

Raytools laser head

Laser cutting head with high precision fiber laser dedicated anti-collision cutting head to ensure high cutting accuracy and cutting efficiency.

Laser cutting head with high precision fiber laser dedicated anti-collision cutting head to ensure high cutting accuracy and cutting efficiency.

Cypcut control system

Cypcut controller is designed for sheet metal processing industry launched a full-featured open-loop control system.

Easy installation, easy adjustment, excellent performance, and complete solutions are popular fiber laser cutting machine control systems.

Cypcut controller is designed for sheet metal processing industry launched a full-featured open-loop control system.

Easy installation, easy adjustment, excellent performance, and complete solutions are popular fiber laser cutting machine control systems.

Machine P arameter s

Applications

Suitable for processing metal sheets such as stainless steel, carbon steel, alloy steel, silicon steel, galvanized steel plate, nickel-titanium alloy, inconel, titanium alloy, etc.

| Model | FL-P2030 | FL-P5050 | FL-P6060 |

| Working Area (L*W) | 200*300mm | 500*500mm | 600*600mm |

| X/Y Axis Position Accuracy | ±0.03mm/1000mm | ±0.03mm/1000mm | ±0.03mm/1000mm |

| X/Y Axis Repeat Position Accuracy | ±0.02mm | ±0.02mm | ±0.02mm |

| Max Moving Speed | 80000mm/min | 80000mm/min | 80000mm/min |

| Max Acceleration | 1.0g | 1.0g | 1.0g |

| Power Supply | AC380V/50Hz | AC380V/50Hz | AC380V/50Hz |

| Laser Source Power(Optional) | 1kW/1.5kW/2kW/2.5kW/3kW/4kW/6kW/8KW/10KW/12KW | ||

Applications

Suitable for processing metal sheets such as stainless steel, carbon steel, alloy steel, silicon steel, galvanized steel plate, nickel-titanium alloy, inconel, titanium alloy, etc.