Basic Info.

Product Description

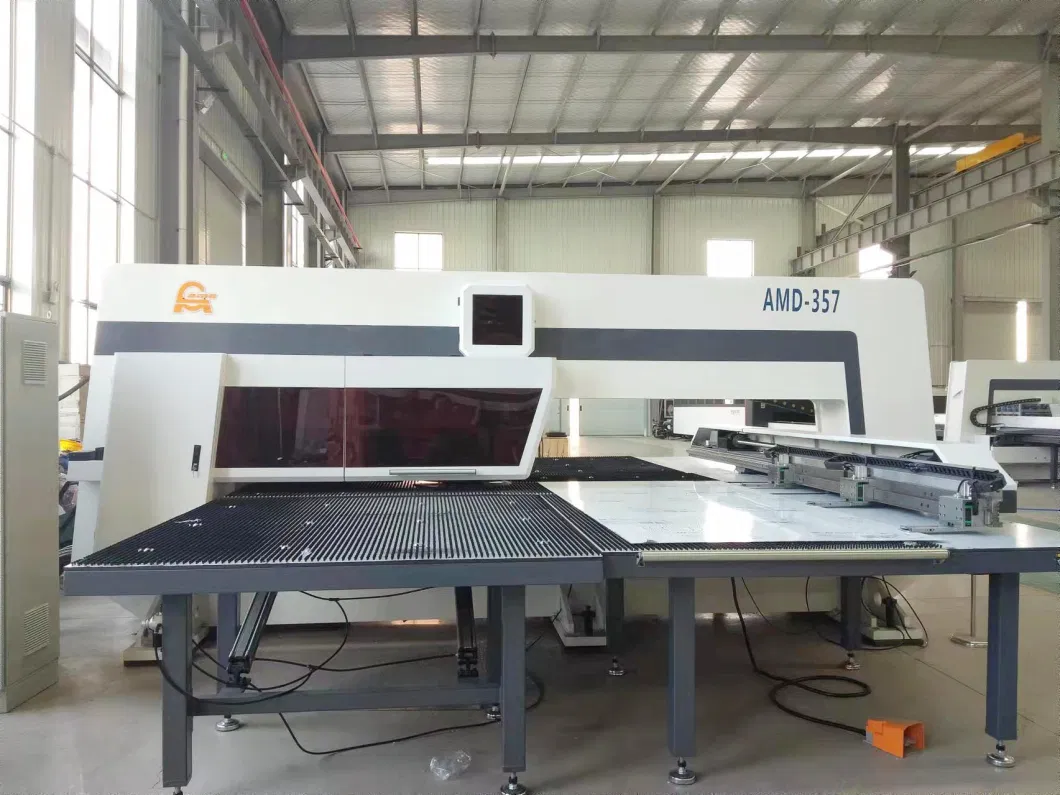

| Specification | unit | AMD-357 |

| Transmission mode | KN | 300 |

| Power rating | kw | 20 |

| Processing sheet size | mm | 2500*1250 |

| Processing sheet thickness | mm | ≤6 |

| Max.Punch Diameter | mm | 88.9 |

| Sheet moving speed | M/min | 40/60 |

| Punching frequency | hpm | 800 |

| Hole accuracy | mm | 0.1 |

| Number of stations in turret | NO. | 16/24/32 |

| Turret speed | rpm | 30 |

| Controlled axis | No. | 3/4 |

| Rotating location | No. | 0/2 |

| Air pressure | mpa | ≥0.8 |

| Outline dimension | mm | 4490*5300*2110 |

| Machine weight | T | 13 |

| Station | Size | Station No | ||

| 16 | 24 | 32 | ||

| A | 3mm~12.7mm | 8 | 12 | 16 |

| B | 12.7mm~31.7mm | 4 | 8 | 12 |

| C | 31.7mm~50.8mm | 2 | 2 | 2 |

| D | 50.8mm~88.9mm | 2 | 2 | 2 |

Main configuration of Turret Punching Machine CNC

Control system: SIEMENS

Servo motor: YASKAWA (from Japan)

Servo amplifier: YASKAWA (from Japan)

Precision ball screw assemblies: TBI (from taiwan)

Precision liner roller rail: ABBA (from taiwan)

Electric parts: OMRON

Advantages of hydraulic series cnc turret punching machine:

1.Au-to index station function effectively solve the irregular angle's shear difficulties.

2.Adopts Siemens CNC special system and match up digital AC servo motor to make if fast and reliable.

3.O type steel plate welding press, the whole pass by tempering treatment to own good rigid and hardly deformation.

4.High decision digital hydraulic main transmission system, speed is faster, stroke is adjustable.

5.Equipped with the second positioning function, processing, the clamp automatically avoid, which can achieve without dead zone processing.

6.The transmission system use the international brand with high precision, long guide screw, linear guide rail are high precision and good performance.

7.Main pneumatic components, electric components, hydraulic components adopts international well-known brand products,which makes the punch press performance more perfectly.

8.Uses AMADA standards casting integrated type thick turret mold disc and standards thick turret international molds.

Our service of CNC Turret Punching machine:

| 1 | Reply your inquiry in 12 working hours. |

| 2 | Experienced staffs answer all your questions in time. |

| 3 | Customized design is available. |

| 4 | Exclusive and unique solution can be provided to our customer by our professional engineers and staff. |

| 5 | Special discount and protection of sales are provided to our distributor. |

| 6 | We are professional manufacturer of sCNC punching Machine. Have a professional design team with more than 10 years design experience engineers, competitive with good quality. |

| 7 | As an honest seller, we always use superior raw material, advanced machines, skilled technicians to ensure our products to be finished in high quality and stable feature. |

| 8 | Prompt delivery, site installation and commissioning. |

FAQ:

1. Production time:

20-40 days according to different type.

2. Installation and commissioning time:

10-15 days.

3. Installation and commissioning issue:

We will send 1-2 technicians to help with machine installation and commissioning, customer pays for their tickets, hotel and diet.

4. Warranty time:

12 months from date of commissioning completion, but no more than 18 months from date of delivery.

5. Payment term:

30% as prepayment, balance 70% before delivery or L/C at sight.

6. We supply full English documents:

Including general installation drawings, pit design drawings, manual book, electric wiring diagram, electric manual book and maintenance book, etc.

Welcome to visit our factory in Qingdao!