Basic Info.

Model NO.

SF30-32

Power Source

Servo Press

Precision

High Precision

Certification

GS, ISO 9001

Condition

New

Throat Depth

1250/1500/2000mm

Transport Package

Pallet

Specification

5000*5000*2100mm

Trademark

Richocean

Origin

Qingdao China

HS Code

8462411900

Production Capacity

100sets/Month

Product Description

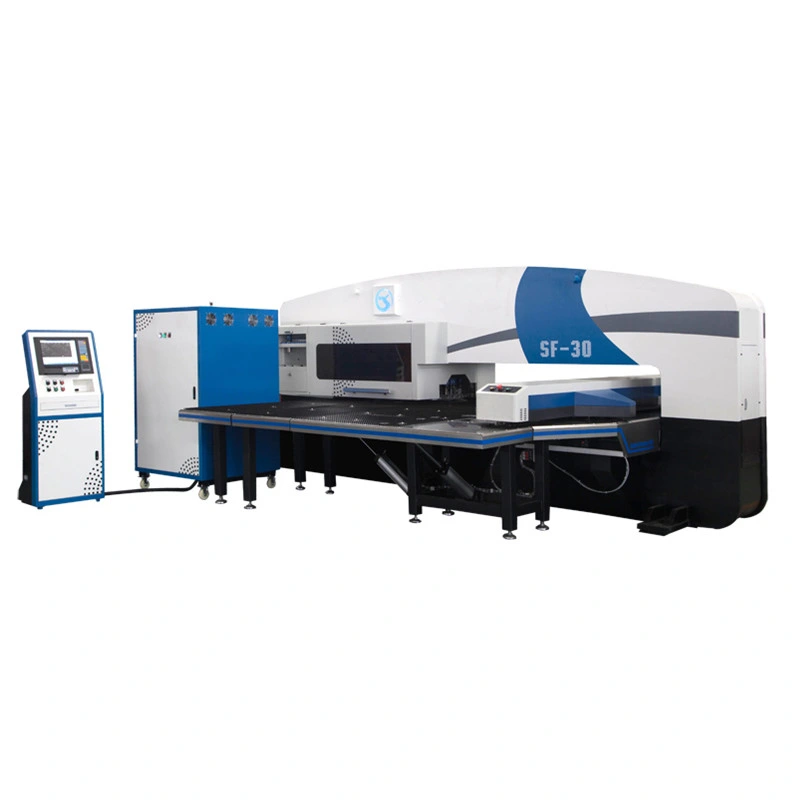

SF30 series Servo CNC turret punch press

Product features:

1.The servo press adopts latest RISC-CPU and fully-digital controller.

2.With program mode,pressure mode,tension mode and quality determination functions,ensuring product quality.

3.Adopting self-adaptive torque control technique and computerized control technique,the punching mechanism can be directly driven.

4.By reducing the punching distance between mold and sheet material and reducing the working stroke of mold,it can extend the service life of molds and lower the service cost of molds.

5.With controllability in the movement of punch pin,capable of programming the movement mode of punch pin suitable for machining process;the punching pin can maintain pressure when operation stops,suitable for processes such as blanking,stretching,coining and bending ect.

6.Pendulum punching control mode is adopted for the punching mode,largely enhancing the punching efficiency.

7.All core components of driver controller adopt components imported from abroad,with reliable precision and stability;unique embedded high-power oil-cooling motor is adopted for the servo motor of punch pin,with advantages of low temperature rise,strong overload capacity,as well ad stability and reliability.

8.Dissipative elements such as flywheel and clutch etc.for mechanical press have been cancelled,the quality of driving parts has been reduced,and the transmission structure has been simplifird.

9.Float-tyoe pneumatic gripper is adopted,strong in griooing force and stable in feeding;integral dovetail carriage,with good rigidity and convenient ingripper movement;the crossbeam is designed as double guide rails,stable in feeding and accurate in positioning.

10.Stainless steel composite table face is adopted,with double-lifting universal-joint steel-ball and brush.

Main technical parameters:

| No. | Name | Parameter | Unit | Note |

| 1 | Punch force | 300(30) | KN(T) | |

| 2 | Rack structure | O-shaped closed-type | mm | Electric frnace tempering |

| 3 | Max.processing size | X-axis 2500 Y-axix 1250 | mm | Secondary positioning Able to process 5000mm |

| 4 | Max.processing thickness | 6 | mm | |

| 5 | Max.punch diameter | φ88.9 | mm | Non-standard customization |

| 6 | Hit speed | 800 | Times/minute | |

| 7 | No.of control shafts | 5(X,Y,Z,T,C) | PCs | |

| 8 | Mold type | Long guide 85 series international standard mold | ||

| 9 | Turret station distribution | A,B,C,D | Standard equipped | Non-standard customization |

| 10 | Mold processing life | 500 thousand | Times | |

| 11 | Repositioning cylinder | 2 | Sets | |

| 12 | Max.feeding speed | X-axis 80/Y-axis 80 | m/min | |

| 13 | Table structure | Seamless brush/universal-jiot steel-ball table composite face | Stainless steel edged | |

| 14 | Max.turret speed | 40 | rpm | |

| 15 | Repositioning accuracy | 0.02 | mm | |

| 17 | Combined working piower | 16 | KW | |

| 18 | Air supply pressure | 0.55 | Mpa | |

| 20 | Power supply | 380±5% | V | |

| 21 | Mold service life | 50 | X104 | |

| 22 | Outline dimension | Length x width x height 5200x5000x2100 | Mm |

Product features:

1.The servo press adopts latest RISC-CPU and fully-digital controller.

2.With program mode,pressure mode,tension mode and quality determination functions,ensuring product quality.

3.Adopting self-adaptive torque control technique and computerized control technique,the punching mechanism can be directly driven.

4.By reducing the punching distance between mold and sheet material and reducing the working stroke of mold,it can extend the service life of molds and lower the service cost of molds.

5.With controllability in the movement of punch pin,capable of programming the movement mode of punch pin suitable for machining process;the punching pin can maintain pressure when operation stops,suitable for processes such as blanking,stretching,coining and bending ect.

6.Pendulum punching control mode is adopted for the punching mode,largely enhancing the punching efficiency.

7.All core components of driver controller adopt components imported from abroad,with reliable precision and stability;unique embedded high-power oil-cooling motor is adopted for the servo motor of punch pin,with advantages of low temperature rise,strong overload capacity,as well ad stability and reliability.

8.Dissipative elements such as flywheel and clutch etc.for mechanical press have been cancelled,the quality of driving parts has been reduced,and the transmission structure has been simplifird.

9.Float-tyoe pneumatic gripper is adopted,strong in griooing force and stable in feeding;integral dovetail carriage,with good rigidity and convenient ingripper movement;the crossbeam is designed as double guide rails,stable in feeding and accurate in positioning.

10.Stainless steel composite table face is adopted,with double-lifting universal-joint steel-ball and brush.