Basic Info.

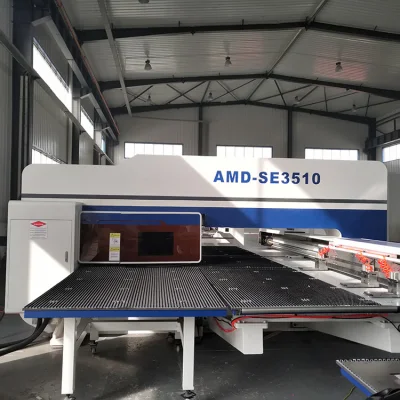

Model NO.

AMD-SE

Power Source

Hydraulic Pressure

Precision

High Precision

Certification

GS, CE, RoHS, ISO 9001

Condition

New

Processing Sheet Thickness

up to 6mm(Mild Steel)

Electric Control System

Siemens 808d, Fanuc, H+L, Fagor, Rexroth

Control System

Siemens, Fanuc, Ipc

After-Sales Service Provided

Available to Service Overseas

Punching Frequency

600-800hpm

Warranty

One Year

Sheet Moving Speed

40m/Min

Dimension(L*W*H)

4490*5300*2110mm

Hole Shapes

Round, Square, Rectangle, Kidney Shape

Loading

20′ot Container or 40gp Container

Transport Package

Foam and Plastic Film/Customized

Specification

CE

Trademark

AMADA

Origin

Shandong China(Mainland)

HS Code

8462101000

Production Capacity

300 Sets Per Year

Product Description

Servo Type CNC Punching Equipment / CNC Punching Press Machine

Features:

Notice:

According to your requirements, the most suitable machines will be designed for your workpieces, please indicate the following details.

1. Please tell us your metal sheet material.

2. The workpiece dimension (including length, width and thickness).

3. The information of hole shapes and hole diameter that you want to punch.

4. It's my pleasure if you can send some photos or drawings of your products for our reference.

Based on these details information, the detailed technical proposals will be sent to you for reference.

Warmly welcome you to visit our factory in Qingdao China.

Features:

·Equipped Fanuc 5 axis CNC system, Fanuc CNC punch servo module, can realize 5 axis control at the same time.

·Equipped with USB, R232 communication interface which can realize the front desk, backstage programming. ·Fuselage is O type Steel welding, the whole pass by tempering treatment to own good rigid and hardly deformation.

·Equipped high strength nodular cast iron to cast into integral thick turret mold plate, thickness is 80mm, through heat treatment to get rid of internal stress, rigid good, precision stability, impact resistant ability good; greatly improving mold service life.

·Equipped with high precision servo initiative transmission system, speed is faster and stroke is adjustable. · With the second positioning function, can achieve processing without dead zone.

·The transmission system use original Taiwan brand with high precision, big guide the ball screw, linear guide rail are high precision and good performance.

·Main pneumatic components, electric components, hydraulic components and transmission components adopt international well-known brand product, which makes the punch work perfectly.

·Equipped with concentrated lubricating device, reduce friction and improve service life.

·Equipped with 2 sets of auto-index station, can easily punch holes with different degrees.

·Equipped with USB, R232 communication interface which can realize the front desk, backstage programming. ·Fuselage is O type Steel welding, the whole pass by tempering treatment to own good rigid and hardly deformation.

·Equipped high strength nodular cast iron to cast into integral thick turret mold plate, thickness is 80mm, through heat treatment to get rid of internal stress, rigid good, precision stability, impact resistant ability good; greatly improving mold service life.

·Equipped with high precision servo initiative transmission system, speed is faster and stroke is adjustable. · With the second positioning function, can achieve processing without dead zone.

·The transmission system use original Taiwan brand with high precision, big guide the ball screw, linear guide rail are high precision and good performance.

·Main pneumatic components, electric components, hydraulic components and transmission components adopt international well-known brand product, which makes the punch work perfectly.

·Equipped with concentrated lubricating device, reduce friction and improve service life.

·Equipped with 2 sets of auto-index station, can easily punch holes with different degrees.

| Specification | Unit | Specification model | |

| Punch Force | KN | 200 | 300 |

| Max.Processing Size | mm | 1250*1250 | 1250*1250 |

| 1250*2500 | 1250*2500 | ||

| 1250*5000 | 1250*5000 | ||

| Max.Sheet Thickness | mm | 4 | 6 |

| Punching Frequency | hpm | 1600 | 1600 |

| Max.Sheet Traversing Speed | m/min | 80 | 80 |

| Turret Speed | rpm | 40 | 40 |

| Hole Accuracy | mm | ±0.1 | ±0.1 |

| Max Punch Diameter | mm | φ88.9 | φ88.9 |

| Number of stations in turret | No. | 24/32 | 24/32 |

| Air Pressure | mpa | 0.8 | 0.8 |

| Controlled Axis | No. | 4(X,Y,C,A) | 4(X,Y,C,A) |

| Prower Rating | KW | 30 | 35 |

| Outline Dimension | mm | 4490*53300*2110 | 4490*5300*2110 |

| Machine Weight | T | 13 | 14 |

Notice:

According to your requirements, the most suitable machines will be designed for your workpieces, please indicate the following details.

1. Please tell us your metal sheet material.

2. The workpiece dimension (including length, width and thickness).

3. The information of hole shapes and hole diameter that you want to punch.

4. It's my pleasure if you can send some photos or drawings of your products for our reference.

Based on these details information, the detailed technical proposals will be sent to you for reference.

Warmly welcome you to visit our factory in Qingdao China.