Basic Info.

Model NO.

Robitic cnc press brake

Type

Press Brake

Transport Package

Wooden Case

Specification

5200x2100x1560mm

Trademark

Prima

Origin

Nanjing, China

HS Code

8456901000

Production Capacity

25

Product Description

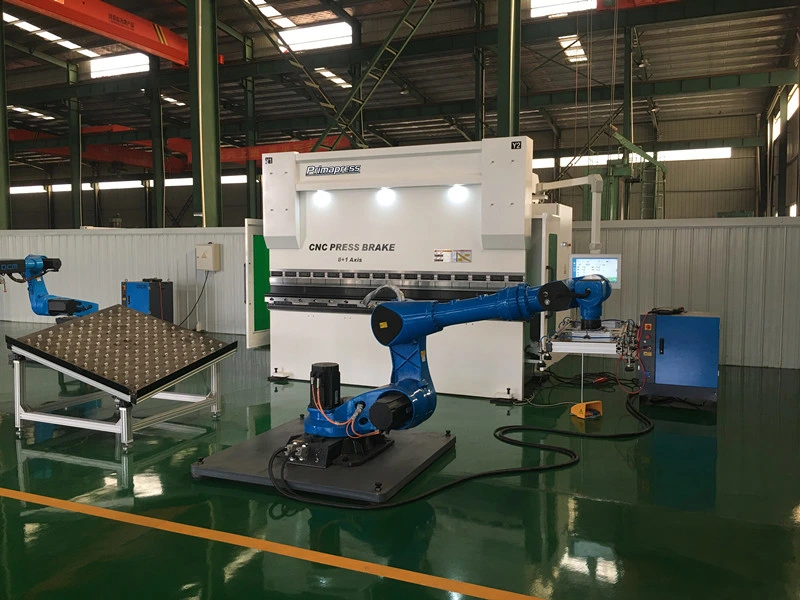

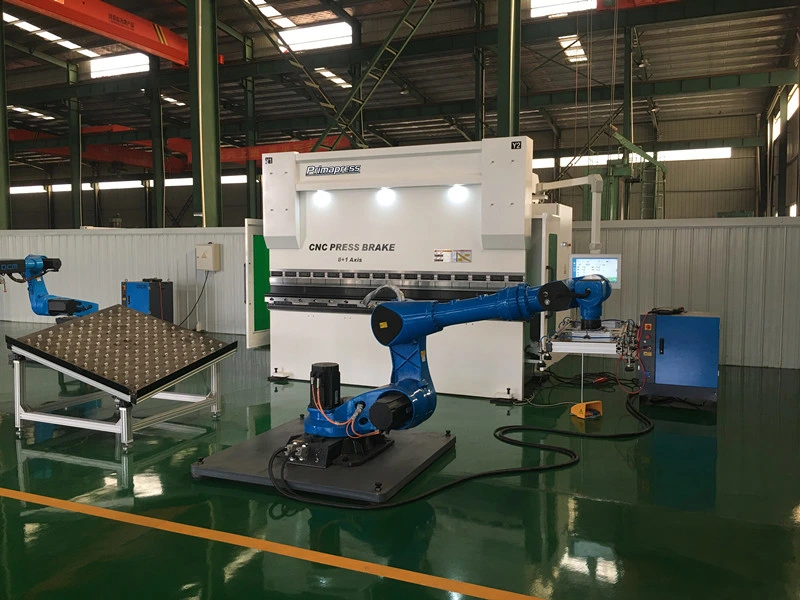

Made in China cnc bending machine Amada design Hydraulic press brake for stainless steel bending Robotic Bending Cell System for Automatic robot press brake of sheet metal Robotic Press Brake Bending Cell Automatic bending machine cell , Automatic bender machine 4.0 automated and robotic bending and shearing lines

Product introduction

The Whole Structure of Press Brake:

Totally European design, streamlined looking

Taking off inner-stress of welded parts by tempering, good stability

Remove rust with sand-blast and coated with anti-rust paint

Adopt Spanish pentahedron machine center, once clamping can finish all working surfaces which will

guarantee dimension precision and position precision.

The design of the machine frame is a critical part of any machine with relation to its ability to produce accurate parts for a long period of time.

Frames, assembly surfaces and connection holes are machined after the welding process, up to 60' in a single pass.

Supplying three front sheet supports , Finish of Nippon Polyurethane paint. Robotic Press Brake Bending Cell Robitic cnc press brake 125T 4000 for sale Flexible Bending Cells-6-axis Robot

The Whole Structure of Press Brake:

Totally European design, streamlined looking

Taking off inner-stress of welded parts by tempering, good stability

Remove rust with sand-blast and coated with anti-rust paint

Frames, assembly surfaces and connection holes are machined after the welding process, up to 60' in a single pass.

Supplying three front sheet supports , Finish of Nippon Polyurethane paint Automatic bending machine cell , Automatic bender machine

2) Ram structure:

Upper stroke design for bending, low noise, stable operating situation , Parallel tolerance of Y1 and Y2 is 0.01mm

Y1,Y2 can be programmed separately can work under non-balance load, can bend cone-shape work piece

At bottom dead center a pressure-keeping time is offered, and can be programmed to assure precision of all kinds of work piece. Can move the ram up slowly, which allows the operator to control work piece conveniently Universal fixing-surface of the upper tool can be meeting with the clamping requirement of the tool farthest!

Hydraulic system is from Rexroth, Germany, a full loop electric-hydraulic proportional servo control, Sumitomo oil pump, Japan.

Imported linear optical reader, guiding system, positioning system and hydraulic balancing system with

high precision, which all can permit the processing work piece of full length or with eccentric.

An outfit with "C" is at throat, as deformation compensation on throat, directly measuring the distance

between upper tool and low die, assuring the precision of work piece.

All seals in cylinder is imported, the most famous brand, good quality and high performance

Overload overflow protection is outfitted to hydraulic system, which can assure no leakage, and the oil level

can be read or seen directly

Being able to work under rated load continuously, stable working and high precision

4) CNC Back gauge:

Close loop electro-hydraulic synchronized servo-control system,the most advanced

Good for work piece needing multiple steps of bending with high precision requirement.

X is moved with ball screw,guided by linear guide,and driven by digital AC servo-motor.

Back gauge has well enough mechanical strength and rigidity with tank-type gauge structure.

Two fingers are moving alone swallow guide,operate easily with high precision

Particular finger-stop design,enlarge the range of back gauge. 4.0 automated and robotic bending and shearing lines

Attachment with the machine& Machine key components list

Detailed Photos:

Technical specifications:

About Prima Factory: High performance Automatic bending cell cnc press brake with Robot

Nanjing Prima CNC Machinery Co., Ltd. is located in the center of China's machine tool industry, Mingjue Industrial Park , Shiqiu Town, Lishui Zone, Nanjing Our company specializes in Table type CNC Fiber Laser cutting machine, exchangeable table cnc fiber laser cutting machine, press brake, shearing machine , ironworker, punching machine , HVAC ducting machine and other metal forming forging equipment development and sales, our product positioning in the middle-top quality class. We commit a modern enterprise management methods, committed management and meticulous management and zero defect operation. Based on the quality of the product management, its excellent quality, innovative design, reasonable price, and improve after-sales service to win the majority of Chinese and foreign customers praise. Primapress Brand sheet metal processing equipment. Widely used in automobile manufacturing, communications, computers and so on. Prima CNC insist on leading technology strategy, positioning in the "do-class machine, a first-class brand," the high level of long-term sales of CNC machine tools in the process, not only to cultivate a number of series of numerical control products, while cultivating a group of skilled, practical style of high-quality workforce. Enterprises have their own research and development institutions, with the domestic strong product research and development of skills. Primapress specializes in the export business, our company already has CE certification and have one international after-sales team , Our machines are widely exported to Southeast Asia, EU, USA , South America, the Middle East and other markets around 100 nations with good quality, suitable price, comprehensive after-sales service, was widely welcomed by customers and unanimously approved. Our company ambition is "build quality brand, do excellent machine",it is also the company's entrepreneurial spirit and look forward to domestic and overseas friends to visit.

FAQ:

Product introduction

The Whole Structure of Press Brake:

Totally European design, streamlined looking

Taking off inner-stress of welded parts by tempering, good stability

Remove rust with sand-blast and coated with anti-rust paint

Adopt Spanish pentahedron machine center, once clamping can finish all working surfaces which will

guarantee dimension precision and position precision.

The design of the machine frame is a critical part of any machine with relation to its ability to produce accurate parts for a long period of time.

Frames, assembly surfaces and connection holes are machined after the welding process, up to 60' in a single pass.

Supplying three front sheet supports , Finish of Nippon Polyurethane paint. Robotic Press Brake Bending Cell Robitic cnc press brake 125T 4000 for sale Flexible Bending Cells-6-axis Robot

The Whole Structure of Press Brake:

Totally European design, streamlined looking

Taking off inner-stress of welded parts by tempering, good stability

Remove rust with sand-blast and coated with anti-rust paint

Frames, assembly surfaces and connection holes are machined after the welding process, up to 60' in a single pass.

Supplying three front sheet supports , Finish of Nippon Polyurethane paint Automatic bending machine cell , Automatic bender machine

2) Ram structure:

Upper stroke design for bending, low noise, stable operating situation , Parallel tolerance of Y1 and Y2 is 0.01mm

Y1,Y2 can be programmed separately can work under non-balance load, can bend cone-shape work piece

At bottom dead center a pressure-keeping time is offered, and can be programmed to assure precision of all kinds of work piece. Can move the ram up slowly, which allows the operator to control work piece conveniently Universal fixing-surface of the upper tool can be meeting with the clamping requirement of the tool farthest!

Hydraulic system:

Close loop electro-hydraulic synchronized servo-control system, the most advanced Hydraulic system is from Rexroth, Germany, a full loop electric-hydraulic proportional servo control, Sumitomo oil pump, Japan.

Imported linear optical reader, guiding system, positioning system and hydraulic balancing system with

high precision, which all can permit the processing work piece of full length or with eccentric.

An outfit with "C" is at throat, as deformation compensation on throat, directly measuring the distance

between upper tool and low die, assuring the precision of work piece.

All seals in cylinder is imported, the most famous brand, good quality and high performance

Overload overflow protection is outfitted to hydraulic system, which can assure no leakage, and the oil level

can be read or seen directly

Being able to work under rated load continuously, stable working and high precision

4) CNC Back gauge:

Close loop electro-hydraulic synchronized servo-control system,the most advanced

Good for work piece needing multiple steps of bending with high precision requirement.

X is moved with ball screw,guided by linear guide,and driven by digital AC servo-motor.

Back gauge has well enough mechanical strength and rigidity with tank-type gauge structure.

Two fingers are moving alone swallow guide,operate easily with high precision

Particular finger-stop design,enlarge the range of back gauge. 4.0 automated and robotic bending and shearing lines

Attachment with the machine& Machine key components list

| No. | 1 years spares | Remark | Name | Origin | |

| 1- | Grease gun& foot switch | Free of charge | Asynchronous motor | Siemens, Germany | |

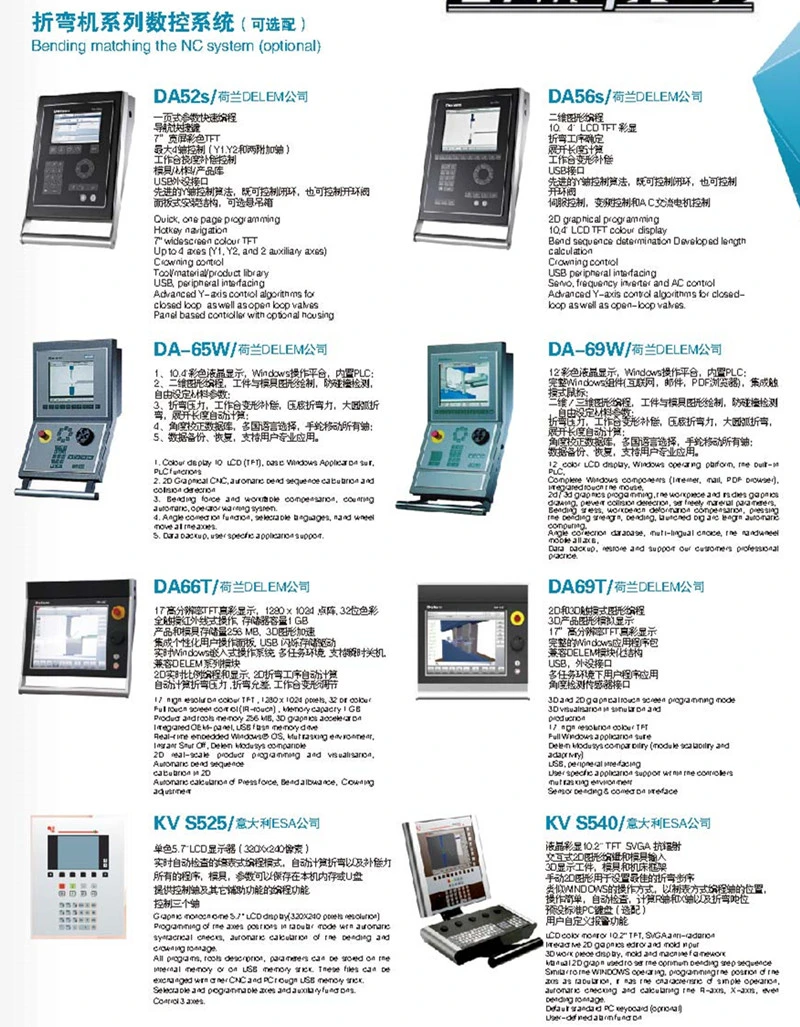

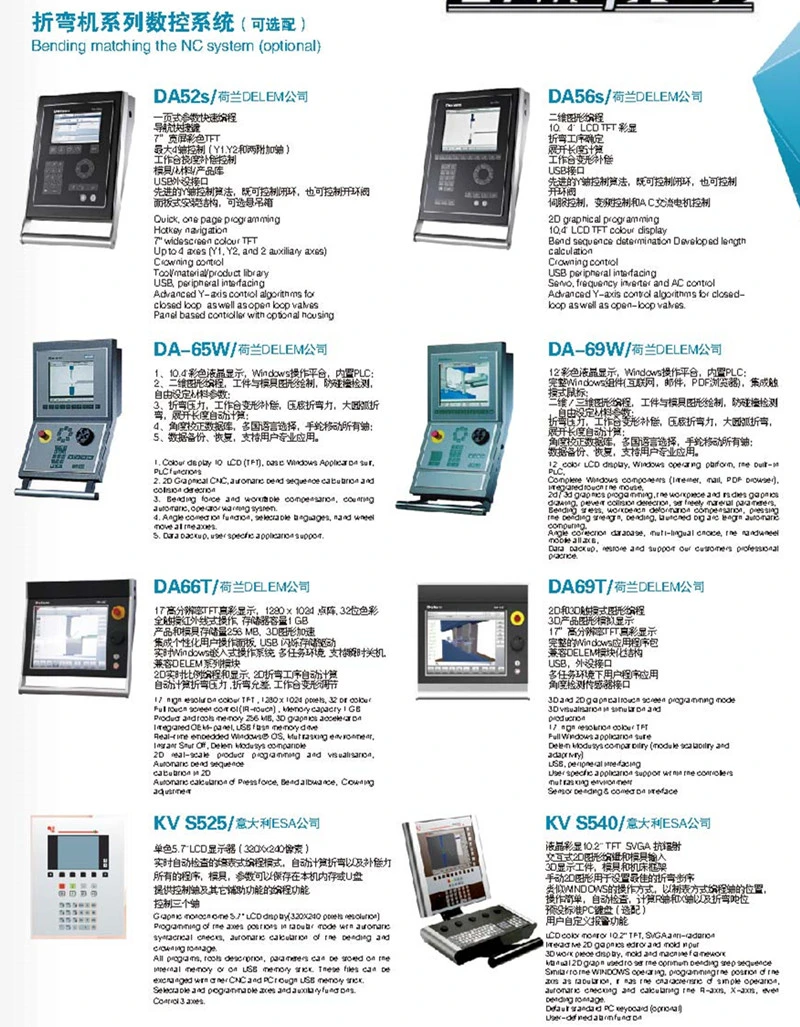

| 2- | Keys to button lock and electric cabinet lock | FOC | Controller | Delem DA52, Holland | |

| 3- | Foundation bolts | FOC | Transformer | SCHNEIDER | |

| 4- | O-type sealing rings | FOC | AC contactor | SCHNEIDER | |

| 5- | Combined washers | FOC | Circuit Breakers | SCHNEIDER | |

| 6- | Mobile type foot switch | Servo motor | Estun | ||

| 7- | Operation & maintenance manual | In English | Gear pump | Siemens pump | |

| 8- | Electrical diagram | In English | Sealing parts | Valqua ,Japan | |

| 9- | Operation Instruction ENGLISH Operation Instruction(Machine) Packing list, Instruction of System Certificates of quality | Hydraulic Integrated Systems | Bosch, Germany, | ||

| Quick release | China Shanghai | ||||

Detailed Photos:

Technical specifications:

| No | Model | Pressure KN | Bending Leng (mm) | Columns Distance (mm) | Open Height (mm) | Throat Depth (mm) | Slide Stroke (mm) | Motor Power (kw) | Machine Size (mm) |

| 1 | 40T/2500 | 400 | 2500 | 1900 | 210 | 200 | 110 | 4 | 2600x1270x1980 |

| 2 | 63T/2500 | 630 | 2500 | 1900 | 235 | 250 | 120 | 5.5 | 2600x1360x2050 |

| 3 | 63T/3200 | 630 | 3200 | 2600 | 235 | 250 | 120 | 5.5 | 3300x1360x2050 |

| 4 | 80T/2500 | 800 | 2500 | 1900 | 320 | 320 | 150 | 7.5 | 2600x1400x2380 |

| 5 | 80T/3200 | 800 | 3200 | 2600 | 320 | 320 | 150 | 7.5 | 3300x1400x2380 |

| 6 | 80T/4000 | 800 | 4000 | 3100 | 320 | 320 | 150 | 7.5 | 4100x1400x2380 |

| 7 | 100T/2500 | 1000 | 2500 | 1900 | 330 | 320 | 150 | 7.5 | 2600x1400x2380 |

| 8 | 100T/3200 | 1000 | 3200 | 2600 | 330 | 320 | 150 | 7.5 | 3300x1400x2380 |

| 9 | 100T/4000 | 1000 | 4000 | 3100 | 330 | 320 | 150 | 7.5 | 4100x1400x2380 |

| 10 | 100T/5000 | 1000 | 5000 | 4100 | 330 | 320 | 150 | 7.5 | 5100x1400x2380 |

| 11 | 125T/2500 | 1250 | 2500 | 1900 | 330 | 320 | 150 | 7.5 | 2600x1400x2380 |

| 12 | 125T/3200 | 1250 | 3200 | 2600 | 330 | 320 | 150 | 7.5 | 3300x1400x2380 |

| 13 | 125T/4000 | 1250 | 4000 | 3100 | 330 | 320 | 150 | 7.5 | 4100x1400x2380 |

| 14 | 125T/5000 | 1250 | 5000 | 4100 | 330 | 320 | 150 | 7.5 | 5100x1400x2380 |

| 15 | 160T/2500 | 1600 | 2500 | 1900 | 400 | 320 | 200 | 11 | 2600x1550x2580 |

| 16 | 160T/3200 | 1600 | 3200 | 2600 | 400 | 320 | 200 | 11 | 3300x1550x2580 |

| 17 | 160T/4000 | 1600 | 4000 | 3100 | 400 | 320 | 200 | 11 | 4100x1550x2580 |

| 18 | 160T/5000 | 1600 | 5000 | 4100 | 400 | 320 | 200 | 11 | 5100x1550x2580 |

| 19 | 160T/6000 | 1600 | 6000 | 4800 | 400 | 320 | 200 | 11 | 6100x1550x2580 |

| 20 | 200T/2500 | 2000 | 2500 | 1900 | 435 | 320 | 200 | 15 | 2600x1650x2900 |

| 21 | 200T/3200 | 2000 | 3200 | 2600 | 435 | 320 | 200 | 15 | 3300x1650x2900 |

| 22 | 200T/4000 | 2000 | 4000 | 3100 | 435 | 320 | 200 | 15 | 4100x1650x2900 |

| 23 | 200T/5000 | 2000 | 5000 | 4100 | 435 | 320 | 200 | 15 | 5100x1650x2900 |

| 24 | 200T/6000 | 2000 | 6000 | 4800 | 435 | 320 | 200 | 15 | 6100x1650x2900 |

| 25 | 250T/2500 | 2500 | 2500 | 1900 | 435 | 320 | 200 | 18.5 | 2600x1750x3070 |

| 26 | 250T/3200 | 2500 | 3200 | 2600 | 435 | 320 | 200 | 18.5 | 3300x1750x3070 |

| 27 | 250T/4000 | 2500 | 4000 | 3100 | 435 | 320 | 200 | 18.5 | 4100x1750x3070 |

| 28 | 250T/5000 | 2500 | 5000 | 4100 | 435 | 320 | 200 | 18.5 | 5100x1750x3070 |

| 29 | 250T/6000 | 2500 | 6000 | 4800 | 435 | 320 | 200 | 18.5 | 6100x1750x3070 |

| 30 | 300T/3200 | 3000 | 3200 | 2600 | 435 | 350 | 200 | 22 | 3300x1850x3285 |

| 31 | 300T/4000 | 3000 | 4000 | 3100 | 435 | 350 | 200 | 22 | 4100x1850x3285 |

| 32 | 300T/5000 | 3000 | 5000 | 4100 | 435 | 350 | 200 | 22 | 5100x1850x3285 |

| 33 | 300T/6000 | 3000 | 6000 | 4800 | 435 | 350 | 200 | 22 | 6100x1850x3285 |

| 34 | 400T/3200 | 4000 | 3200 | 2600 | 520 | 400 | 250 | 37 | 3300x2000x3230 |

| 35 | 400T/4000 | 4000 | 4000 | 3100 | 520 | 400 | 250 | 37 | 4100x2000x3230 |

| 36 | 400T/5000 | 4000 | 5000 | 4100 | 520 | 400 | 250 | 37 | 5100x2000x3230 |

| 37 | 400T/6000 | 4000 | 6000 | 4800 | 520 | 400 | 250 | 37 | 6100x2000x3230 |

| 38 | 400T/7000 | 4000 | 7000 | 5600 | 520 | 400 | 250 | 37 | 7100x2000x3230 |

| 39 | 500T/4000 | 5000 | 4000 | 3100 | 600 | 400 | 300 | 45 | 4100x2400x3710 |

| 40 | 500T/5000 | 5000 | 5000 | 4100 | 600 | 400 | 300 | 45 | 5100x2400x3710 |

| 41 | 500T/6000 | 5000 | 6000 | 4800 | 600 | 400 | 300 | 45 | 6100x2400x3710 |

| 42 | 500T/7000 | 5000 | 7000 | 5600 | 600 | 400 | 300 | 45 | 7100x2400x3710 |

| 43 | 500T/8000 | 5000 | 8000 | 6200 | 600 | 400 | 300 | 45 | 8100x2400x3710 |

| 44 | 600T/4000 | 6000 | 4000 | 3100 | 600 | 400 | 300 | 45 | 4100x2650x3750 |

| 45 | 600T/5000 | 6000 | 5000 | 4100 | 600 | 400 | 300 | 45 | 5100x2650x3750 |

| 46 | 600T/6000 | 6000 | 6000 | 4800 | 600 | 400 | 300 | 45 | 6100x2650x3750 |

| 47 | 600T/7000 | 6000 | 7000 | 5600 | 600 | 400 | 300 | 45 | 7100x2650x3750 |

| 48 | 600T/8000 | 6000 | 8000 | 6200 | 600 | 400 | 300 | 45 | 8100x2650x3750 |

| 49 | 700T/4000 | 4000 | 4000 | 3100 | 640 | 500 | 300 | 55 | 4100x2850x3970 |

| 50 | 700T/5000 | 5000 | 5000 | 4100 | 640 | 500 | 300 | 55 | 5100x2850x3970 |

| 51 | 700T/6000 | 6000 | 6000 | 4800 | 640 | 500 | 300 | 55 | 6100x2850x3970 |

| 52 | 700T/7000 | 7000 | 7000 | 5600 | 640 | 500 | 300 | 55 | 7100x2850x3970 |

| 53 | 700T/8000 | 7000 | 8000 | 6200 | 640 | 500 | 300 | 55 | 8100x2850x3970 |

| 54 | 800T/4000 | 8000 | 4000 | 3100 | 800 | 500 | 400 | 2x37 | 4100x3200x4400 |

| 55 | 800T/5000 | 8000 | 5000 | 4100 | 800 | 500 | 400 | 2x37 | 5100x3200x4400 |

| 56 | 800T/6000 | 8000 | 6000 | 4800 | 800 | 500 | 400 | 2x37 | 6100x3200x4400 |

| 57 | 800T/7000 | 8000 | 7000 | 5600 | 800 | 500 | 400 | 2x37 | 7100x3200x4400 |

| 58 | 800T/8000 | 8000 | 8000 | 6200 | 800 | 500 | 400 | 2x37 | 8100x3200x4400 |

| 59 | 1000T/5000 | 10000 | 5000 | 4100 | 800 | 600 | 400 | 2x45 | 5100x3500x4950 |

| 60 | 1000T/6000 | 10000 | 6000 | 4800 | 800 | 600 | 400 | 2x45 | 6100x3500x4950 |

| 61 | 1000T/7000 | 10000 | 7000 | 5600 | 800 | 600 | 400 | 2x45 | 7100x3500x4950 |

| 62 | 1000T/8000 | 10000 | 8000 | 6200 | 800 | 600 | 400 | 2x45 | 8100x3500x4950 |

| 63 | 1200T/5000 | 12000 | 5000 | 4100 | 900 | 600 | 400 | 2x45 | 5100x3800x5200 |

| 64 | 1200T/6000 | 12000 | 6000 | 4800 | 900 | 600 | 400 | 2x45 | 6100x3800x5200 |

| 65 | 1200T/7000 | 12000 | 7000 | 5600 | 900 | 600 | 400 | 2x45 | 7100x3800x5200 |

| 66 | 1200T/8000 | 12000 | 8000 | 6200 | 900 | 600 | 400 | 2x55 | 8100x3800x5200 |

About Prima Factory: High performance Automatic bending cell cnc press brake with Robot

Nanjing Prima CNC Machinery Co., Ltd. is located in the center of China's machine tool industry, Mingjue Industrial Park , Shiqiu Town, Lishui Zone, Nanjing Our company specializes in Table type CNC Fiber Laser cutting machine, exchangeable table cnc fiber laser cutting machine, press brake, shearing machine , ironworker, punching machine , HVAC ducting machine and other metal forming forging equipment development and sales, our product positioning in the middle-top quality class. We commit a modern enterprise management methods, committed management and meticulous management and zero defect operation. Based on the quality of the product management, its excellent quality, innovative design, reasonable price, and improve after-sales service to win the majority of Chinese and foreign customers praise. Primapress Brand sheet metal processing equipment. Widely used in automobile manufacturing, communications, computers and so on. Prima CNC insist on leading technology strategy, positioning in the "do-class machine, a first-class brand," the high level of long-term sales of CNC machine tools in the process, not only to cultivate a number of series of numerical control products, while cultivating a group of skilled, practical style of high-quality workforce. Enterprises have their own research and development institutions, with the domestic strong product research and development of skills. Primapress specializes in the export business, our company already has CE certification and have one international after-sales team , Our machines are widely exported to Southeast Asia, EU, USA , South America, the Middle East and other markets around 100 nations with good quality, suitable price, comprehensive after-sales service, was widely welcomed by customers and unanimously approved. Our company ambition is "build quality brand, do excellent machine",it is also the company's entrepreneurial spirit and look forward to domestic and overseas friends to visit.

FAQ:

Q1. Trade company or manufacturer?

A: We manufacturer

Q2. Is it easy to operate for the new user ?

A: very easy

Q3. What should I do when the machine is in trouble?

A: Take photos and videos and contact our sales at once.

Q4: How long does it take to learn how to operate a laser cutting machine?

A: A couple of hours

Q5: Is it harmful to human body when in operation ?

A: no,very safe.