Basic Info.

Packaging & Delivery

Product Description

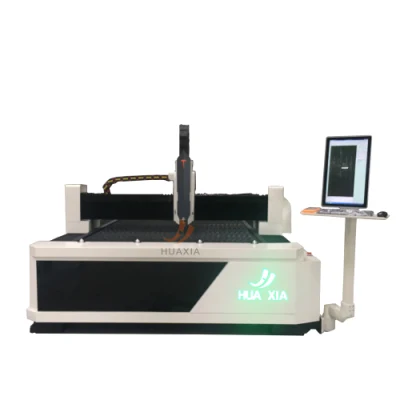

Professional Fiber CNC Metal Laser Cutter for Stainless Carbon Steel

Standard Configuration of Fiber laser cutting machine:

1. Laser generator Wuhan Raycus or Germany IPG

2. Laser cutting torch Raytools

3. Cutting bed Steel plate welding

4. X, Y gear rack Germany ROR or Taiwan YYC

5. Guide rail Taiwan Hiwin

6. AC servo motor & driver Japan Fuji

7. Proportional valve Japan SMC

8. Reducer Japan SHIMPO

9. Gas circuit control Japan SMC

10. CNC system and software CYPCUT

11. Water cooling machine Guangzhou S&A

12. Dust Absorption set

| Technical Parameters | |

| Model | HX-3015-1000W |

| Laser type | fiber laser |

| Laser power | 1000w |

| Machine power | ≤12kw |

| Laser wavelength | 1070-1080nm |

| Working area | 3000mm×1500mm |

| X/Y/Z axis stroke | 1530mm/3050mm/80mm |

| Cutting speed | Depends on the materials and its thickness |

| Repeated positioning accuracy | ±0.02mm |

| Cooling type | water cooling |

| Aiming and positioning | red light |

| Voltage | 3 phase 380V/50Hz/60A |

| Machine occupy space | 9000*5000MM |

Configurations of machine

Equip with Cypcut or NC-Studio (Weihong) control system, Chinese top brands. Integrated special function module for laser cutting control, powerful, good man-machine interface and easy operation.

- Real-time auto-gain tuning

- Manual and auto notch filters

- Manual and auto damping filters

- Setup software with motion simulation

- New structure

- innovative core

- high-precision encoder

- Complies with European safety standards

- Low interference

Gantry: Aluminum alloy die pressure casting, watering integrated beam. Has the advantages of light and stable structure, energy saving, light weight, small inertia and good dynamic performance.

Using high-pressure electrostatic spray treatment, the appearance is elegant and unique, and durable.

The control system adopts liquid crystal Chinese and English conversion computer controller, fully automatic control, simple and intuitive operation.

With automatic fault diagnosis function, the fault point is directly displayed on the screen, prompting the user to process quickly.

Application area

Widely used for :sheet metal cutting, pipe (needs to add another tube cutting device):stainless steel, carbon steel, galvanized sheet, electrolytic plate, brass, aluminum steel, manganese, all kinds of alloy plate,rapid processing and so on.

Widely used in: Electrical power, auto parts, mechanical equipment, electrical equipment, hotel kitchen equipment, elevator equipment, advertising decoration, car decoration, sheet metal chassis cabinets, hardware, lighting, display equipment, precision parts, all kinds of metal cutting industry etc.

Packing and shipping

Contact:

Jinan Huaxia Machinery Equipment Co.,Ltd

Connect Person:Claire