- Overview

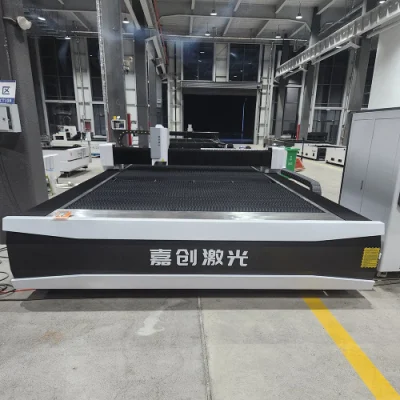

- Product Description

- Cutting Samples

- Factory

Basic Info.

Packaging & Delivery

Product Description

Tenical Data of Metal Laser Cutting Machine

| Model | HY6015S | ||

| Laser Power | 3000W | 6000W | 12000w |

| Max. Cutting Thickness | 20 mm | 25 mm | 30mm |

| Laser Source | MAX | ||

| Laser Head | BM110 | ||

| Working area | 3000*1500 mm | ||

| X axis Stroke | 3020 mm | ||

| Y axis Stroke | 1520 mm | ||

| Z axis Stroke | 150 mm | ||

| Transmission way | Imported Japan THK ball screw | ||

| Table-driven system | Delta | ||

| Focus Method | Dynamic Following and Automatic Adjust Focus | ||

| Location precision | ≤±0.05 mm | ||

| Re-location precision | ±0.02 mm | ||

| Max. moving speed | 100m/min | ||

| Laser wavelength | 1070nm | ||

| Minimum line width | ≤0.1mm | ||

| Supporting Format | PLT, DXF, BMP, AI ,CNC | ||

| Power demand | 380V/50HZ | ||

| Worktable max. load | 5000 Kg | ||

| Dimension (L*W*H) | 4100mmX2200mmX1700mm | ||

| Control Method | offline movement Control | ||

Control software | Raytools XC3000 | ||

1.Max Laser Source

Max Laser Source is the famous laser source brand , Integrating high power, compact size, user-friendly control, high-quality beam quality, and high light conversion efficiency .

2. BM 110 Laser Head

Optimized optical configuration and smooth and efficient airflow design significantly improve cutting quality and efficiency;

Auto focus:

Automatic focusing, reducing human intervention, automatic focusing range -12~+10mm, focusing accuracy 0.05mm;

Multiple protective lenses:

The collimation lens is added to protect the lens, effectively protecting the collimation lens;

Drawer mirror holder:

Quick and easy replacement of protective lenses;

High adaptability:

Equipped with multiple fiber interfaces such as QBH and QD, it can be adapted to various mainstream lasers.

The composite lens group equipped with D30 integrates the light beam, and the optimized optics and water-cooling design enable the laser head to work continuously and stably for a long time under high power.

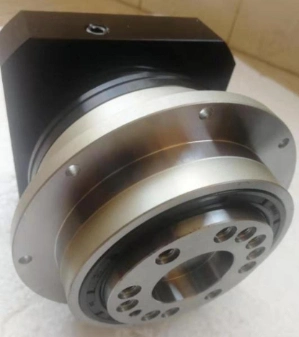

3. Motor and Reducer

Delta motor and Moto reducer, they are a perfect combination. The speed is more than 2 times higher than that of ordinary motors, precise point control, and improved processing efficiency

4. Bed frame

Quenching and tempering process to prevent deformation, reduce vibration, and make the processing accuracy higher

5. Guild Rail and Rack

Famous brand, high quality, not easy to deform, make the machine run more smoothly and stronger.

Our advantage :

More than 20 years of production experience, reliable quality.

The professional team provides overall solutions, not just selling machines.

Perfect after-sales service team, solve any of your problems within 24 hours.

International engineers in 50 countries, free door-to-door service.

Long warranty period, so you can rest assured to buy.

Installation and debugging

Technicians can be sent to the factory for training (free of service fee for the first time). Customers only need to provide accommodation for engineers.

Training

Free of charge for training within warranty. But customers need to take charge of the cost for accommodation, air tickets, visa fee.

24/7 online service

All our laser equipment is provided with 12 months warranty. Hoysook Laser offers free maintenance or replacement service if something is wrong with the equipment under warranty.

Accessories supply

Laser source warranty is 2 years. Other parts is 3 years except for optical and consumable parts.