Basic Info.

Model NO.

KCN-6325

Type

Press Brake

Nanjing City

Jiangsu Province

Transport Package

Plastic

Specification

KCN-6325

Trademark

KINGBALL

Origin

China

HS Code

8462299000

Production Capacity

100 Piece/Mon

Product Description

KCN metal flat bar CNC Bending Metal Machines with CT12 controller

Model: KCN-6325

4+1 Axis CNC Control(X,Y1,Y2,R,W)

X: Backgauge front and back; Y1,Y2, : Left and right oil cylinder stroke

R : Backgauge up and down; W: Worktable crowning

Main functions and features

1.Overall welded and processed structure.

2.Electric hydraulic proportional servo synchronization, ensuring repeated accuracy.

3. Within one stroke, bending pressure can be controlled at random point, repeatability precision±0.01, parallelism 0.02.

4. Lower worktable has crowning device to anti deflection & upper tool has wedge compensation device.

5.Switzerland cybelec CNC control system, grating ruler, Rexroth hydraulics, servo motors and other accessories of famous brand are installed for perfect machine performance.

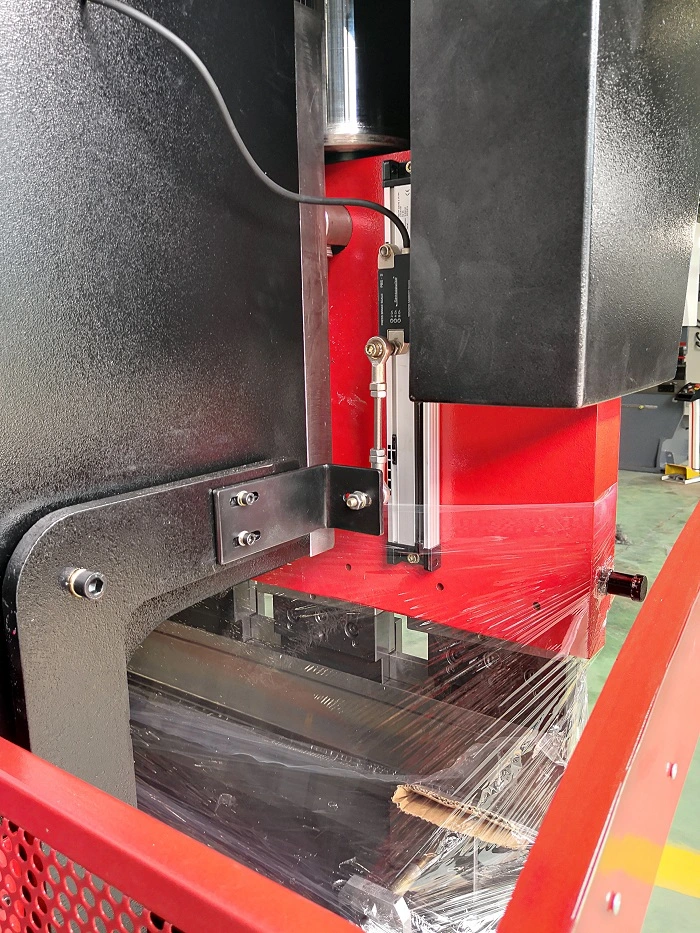

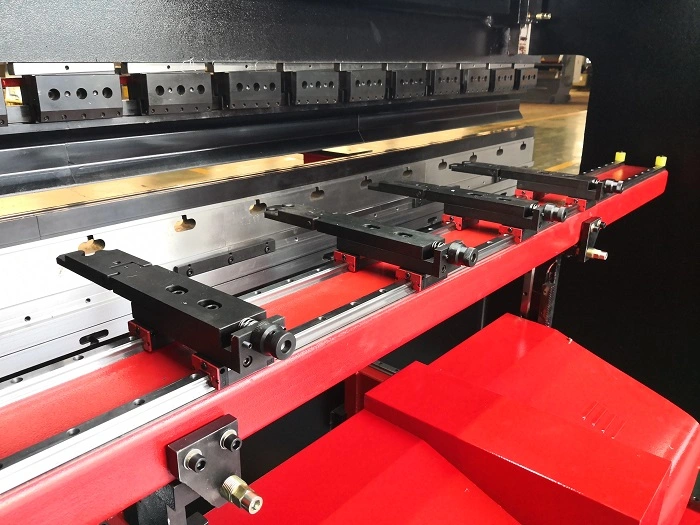

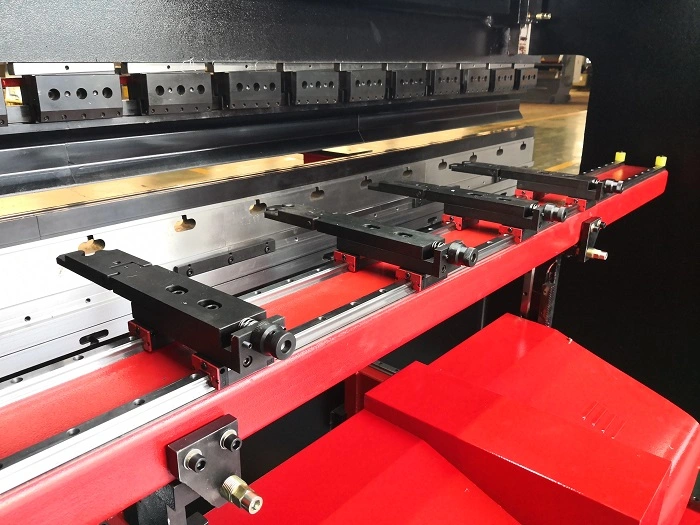

6. Ram stroke(Y1, Y2),backgauge (X, R) are controlled by CNC controller while ball screw and linear guide rail installed for high repeatability precision.

7.Imported ball screw and linear guide are used for rear stopper, to ensure the positioning precision of rear stopper, for processing precision of machine to be higher.

Technical Parameters

Backgauge with ball screw and linear guide, high precision, fast speed and low noise.

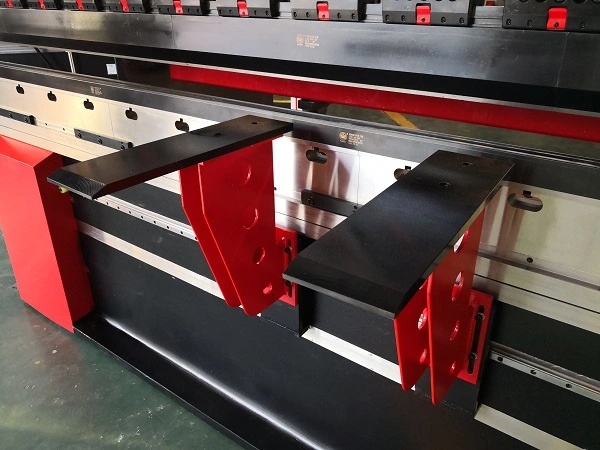

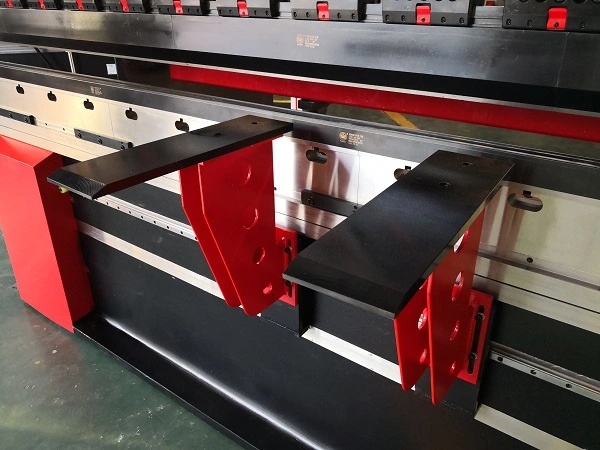

Double sliding front support arm installed High precision electric table crowning

on the linear guide, movable easy

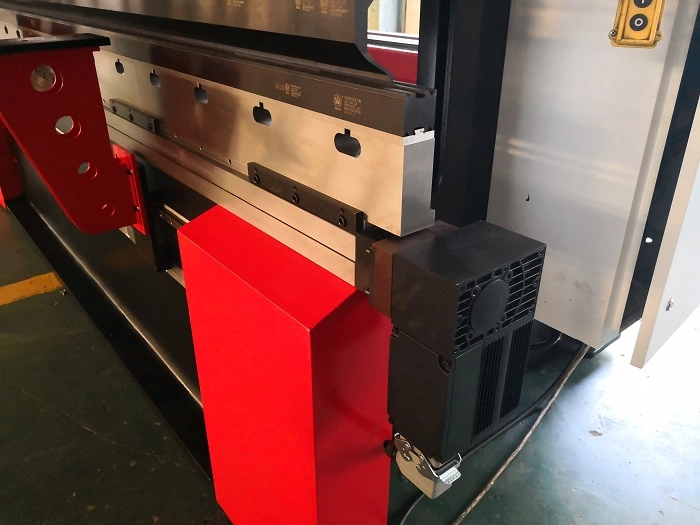

Siemens main motor German brand. European style quick release clamping

Sunny pump USA brand.

Rexroth valve German brand.

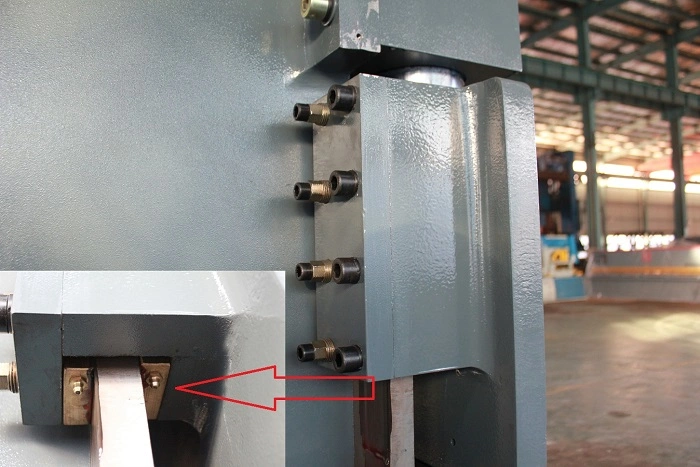

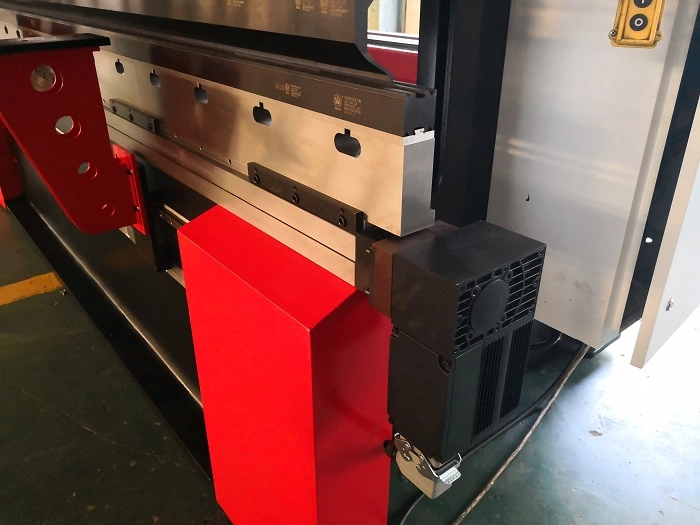

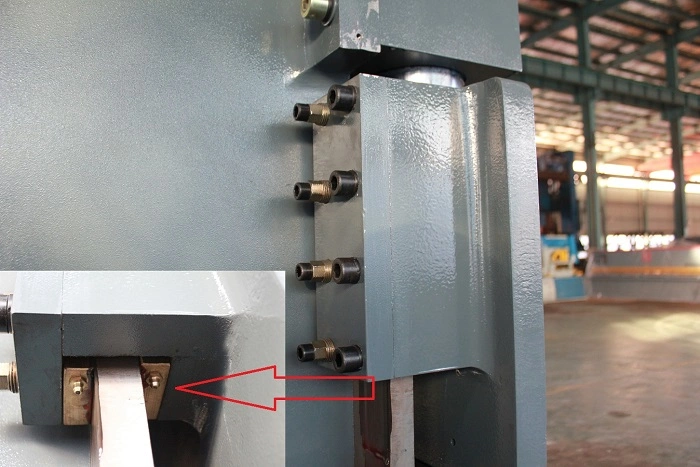

The guideway use the brass, wear-resisting, long service life

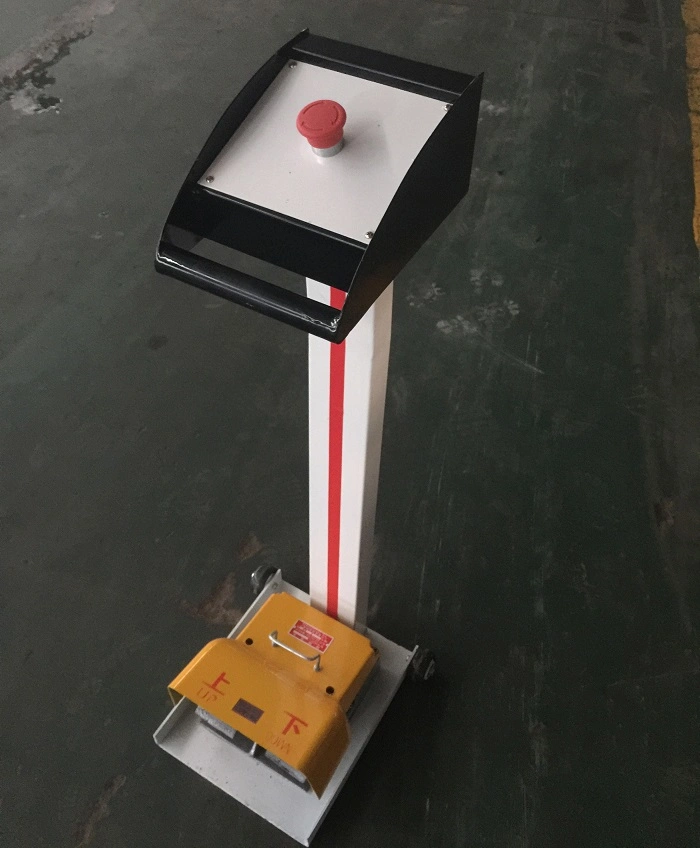

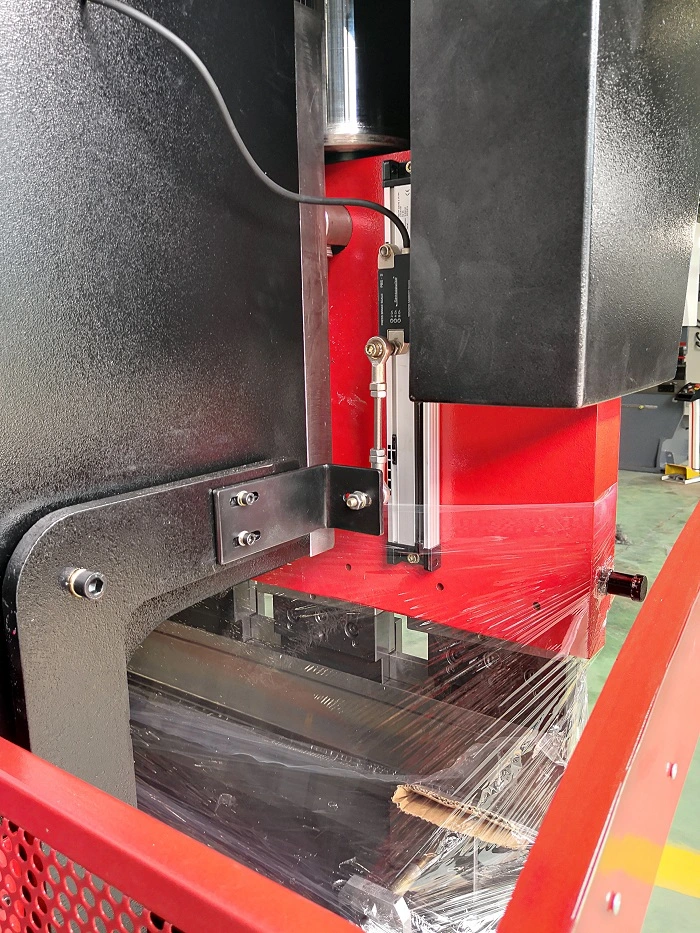

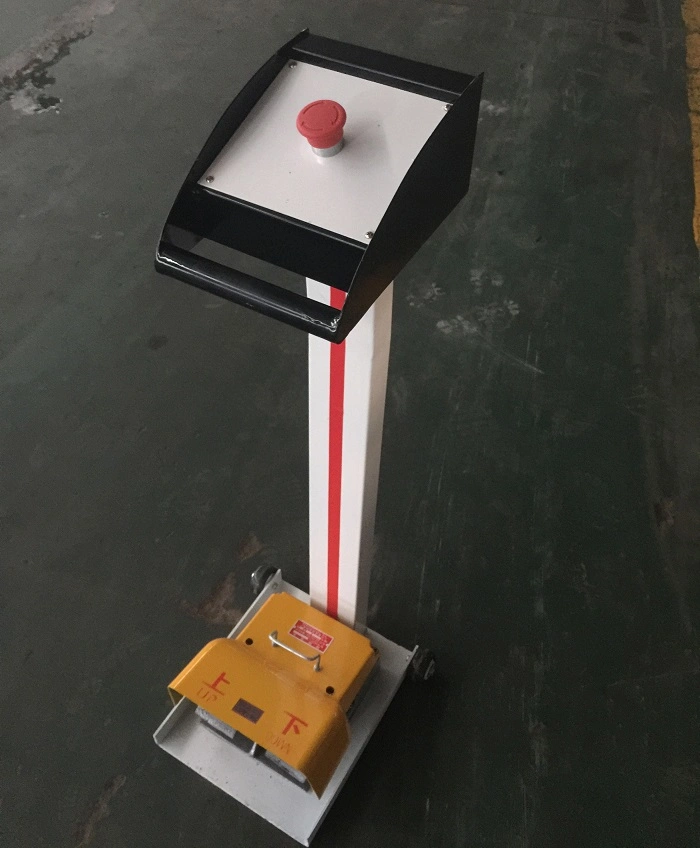

High-precision grating scale mounted Pedal switch with emergency stop.

on C-board.

The stopper move left and right on two linear guides

Main configuration

CybTouch 12 CNC controller

Easy Operating

Large, vivid and high-contrast fully touchscreen.

Simple pages, clear display, large keys.

Intuitive user-friendly interface.

Complete programming for efficient mass-production with multiple bends.

Easy single bends with Easy Bend page.

On-line help and interactive warning pop-ups.

Comfortable wireless data backup and software updating using PC or Notebook.

Large variety of languages available.

Better Bending

Various automatic calculations of bend functions.

Bending sequences and programs can be memorized.

Angle, pressure and crowning management.

Easy manual movement.

Offline 2D software available.

Powerful

Controls 4 axes.

Automatic bend sequencing (option).

Bend allowance calculation.

Pressure - crowning calculation.

Modular tools for each part or bend.

Angle and back gauge correction.

Tele maintenance via wireless connection with PC or notebook.

USB port for memory stick for data transfer/backup.

The standard accessories are in the below:

Model: KCN-6325

4+1 Axis CNC Control(X,Y1,Y2,R,W)

X: Backgauge front and back; Y1,Y2, : Left and right oil cylinder stroke

R : Backgauge up and down; W: Worktable crowning

Main functions and features

1.Overall welded and processed structure.

2.Electric hydraulic proportional servo synchronization, ensuring repeated accuracy.

3. Within one stroke, bending pressure can be controlled at random point, repeatability precision±0.01, parallelism 0.02.

4. Lower worktable has crowning device to anti deflection & upper tool has wedge compensation device.

5.Switzerland cybelec CNC control system, grating ruler, Rexroth hydraulics, servo motors and other accessories of famous brand are installed for perfect machine performance.

6. Ram stroke(Y1, Y2),backgauge (X, R) are controlled by CNC controller while ball screw and linear guide rail installed for high repeatability precision.

7.Imported ball screw and linear guide are used for rear stopper, to ensure the positioning precision of rear stopper, for processing precision of machine to be higher.

Technical Parameters

| NO. | Item | Parameter | Unit | |

| 1 | Nominal pressure | 630 | KN | |

| 2 | Table length | 2500 | mm | |

| 3 | Max.Slider stroke | 165 | mm | |

| 4 | Max.Shut height | 420 | mm | |

| 5 | Between columns | 2100 | mm | |

| 6 | Throat depth | 350 | mm | |

| 7 | Main motor power | 5.5 | KW | |

| 8 | Down Speed | 180 | mm/s | |

| 9 | Pressing Speed | 12 | mm/s | |

| 10 | Return Speed | 160 | mm/s | |

| 11 | Control axis | X+Y1+Y2+R +W | / | |

| 12 | X axis Stroke | 500 | mm | |

| 13 | X axis Speed | 300 | mm/s | |

| 14 | R axis Stroke | 150 | mm | |

| 15 | R axis Speed | 50 | mm/s | |

| 16 | Backgauge Stoppers | 2 | / | |

| L | 3000 | mm | ||

| 17 | Overall dimension | W | 1650 | mm |

| H | 2350 | mm | ||

| 18 | Machine weight | 5600 | kg | |

Backgauge with ball screw and linear guide, high precision, fast speed and low noise.

Double sliding front support arm installed High precision electric table crowning

on the linear guide, movable easy

Siemens main motor German brand. European style quick release clamping

Sunny pump USA brand.

Rexroth valve German brand.

The guideway use the brass, wear-resisting, long service life

High-precision grating scale mounted Pedal switch with emergency stop.

on C-board.

The stopper move left and right on two linear guides

Main configuration

| Name | Producer |

| CNC controller | CT12 Switzerland brand |

| Main motor | Siemens Germany brand |

| Electrical components | Schneider France brand |

| Gear pump | Sunny USA brand |

| Seal ring | NOK Japan brand |

| Hydraulic system | Boschrexroth Germany brand |

| Ball screw ,Linear guide | HIWIN Taiwan brand |

| Grating ruler | GIVI Italy brand |

| Tubing connector | EMB Germany Brand |

| Servo Motor and drive | Thinkvo China brand |

CybTouch 12 CNC controller

Easy Operating

Large, vivid and high-contrast fully touchscreen.

Simple pages, clear display, large keys.

Intuitive user-friendly interface.

Complete programming for efficient mass-production with multiple bends.

Easy single bends with Easy Bend page.

On-line help and interactive warning pop-ups.

Comfortable wireless data backup and software updating using PC or Notebook.

Large variety of languages available.

Better Bending

Various automatic calculations of bend functions.

Bending sequences and programs can be memorized.

Angle, pressure and crowning management.

Easy manual movement.

Offline 2D software available.

Powerful

Controls 4 axes.

Automatic bend sequencing (option).

Bend allowance calculation.

Pressure - crowning calculation.

Modular tools for each part or bend.

Angle and back gauge correction.

Tele maintenance via wireless connection with PC or notebook.

USB port for memory stick for data transfer/backup.

The standard accessories are in the below:

- Anchor bolt

- Hex nut

- Seal ring

- Gasket

- Grease gun

- Allen wrench

- Foot switch

- Front support arms

- Electrical box key, control panel key

- Operation manuals