Basic Info.

Model NO.

YX150-SA

Pressing Layer

Single Layer

Work Mode

Continuous

Controlling Mode

Artificial

Automatic Grade

Manual

Certification

CE

After-sales Service

1 Year

Machine Name

Plywood Curved Press

Application

Plywood Seats,Backs and So on

Working Principle

High Frequency Dielectric Heating

Working Type

One Drive Two

High Frequency Generator

20/30kw

Working Table Size

1600X800mm or 2500X1300mm

Vertical Pressure

80 Ton and 150 Ton

Horizontal Pressure

60 Ton

Hydraulic Cylinder Stroke

600mm

Opening

1100mm

Transport Package

Exporting Packing

Specification

2500x1300mm

Origin

China

HS Code

8514400090

Production Capacity

1000 Sets Per Year

Product Description

High Frequency Hydraulic Wood Bending Press For Skateboard Decking SAGA

High frequency curved plywood press applies high frequency generator to hydraulic press, by mold and electro, it transfers the high frequency power to the work piece to achieve the function of fast gluing and forming. It's suitable for BENT PLYWOOD CHAIR, BENT OR ARC PLYWOOD FOR THE FURNITURE OR BED or other bent plywood products like CLOTH HANGER OR SURFACE OF MUSICAL INSTRUMENT.

Technicial Parameter

Actual Working

Application

Charactor of High Frequency Curved Plywood Press

A.Fast and uniformly heating

B.Bending shape is stable, not easy to change de-lamination.

C.High frequency power is a selectively heating power, it concentrates only on water or glue. wood cannot consume high frequency power, so it is effective and power saving.

D.Wooden or MDF mold used, much economic than metal mold if shape is frequency changed.

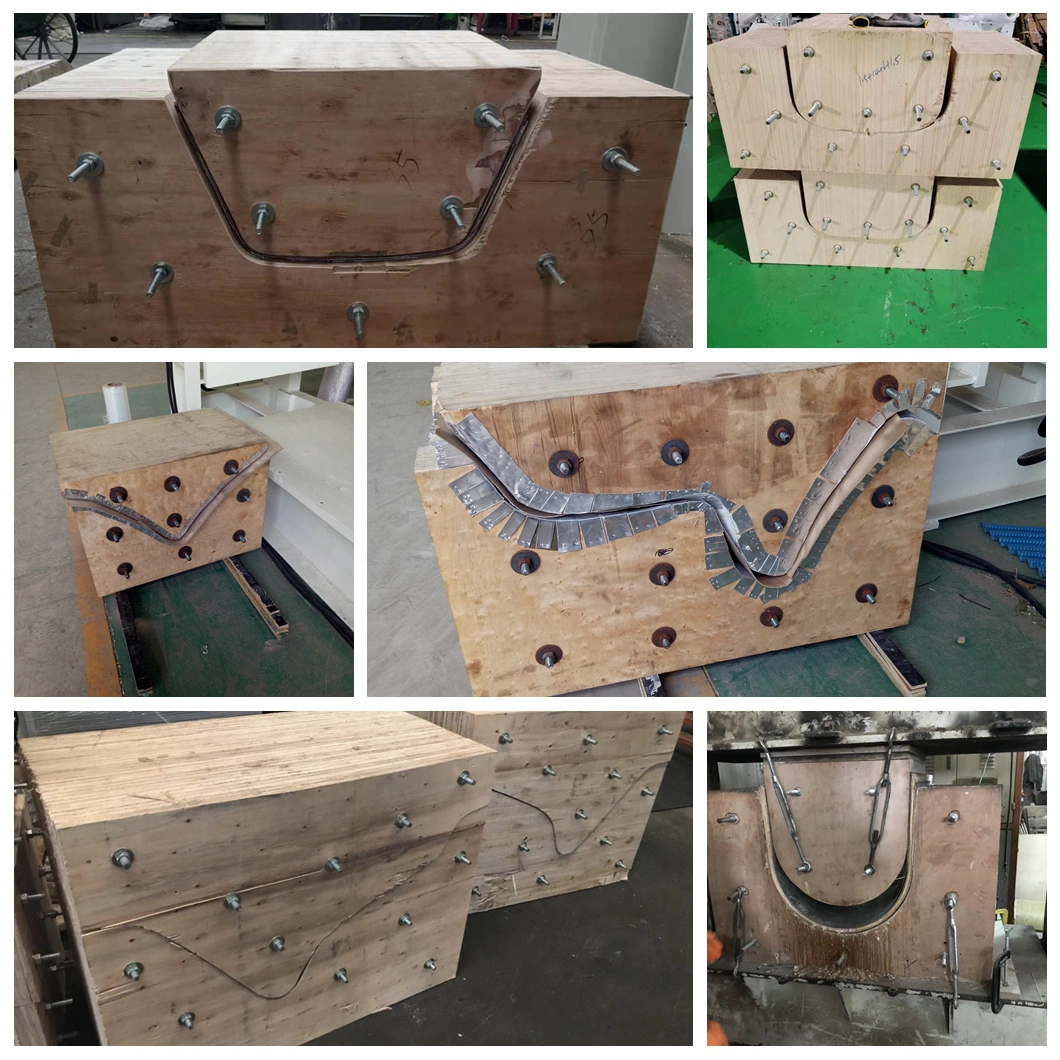

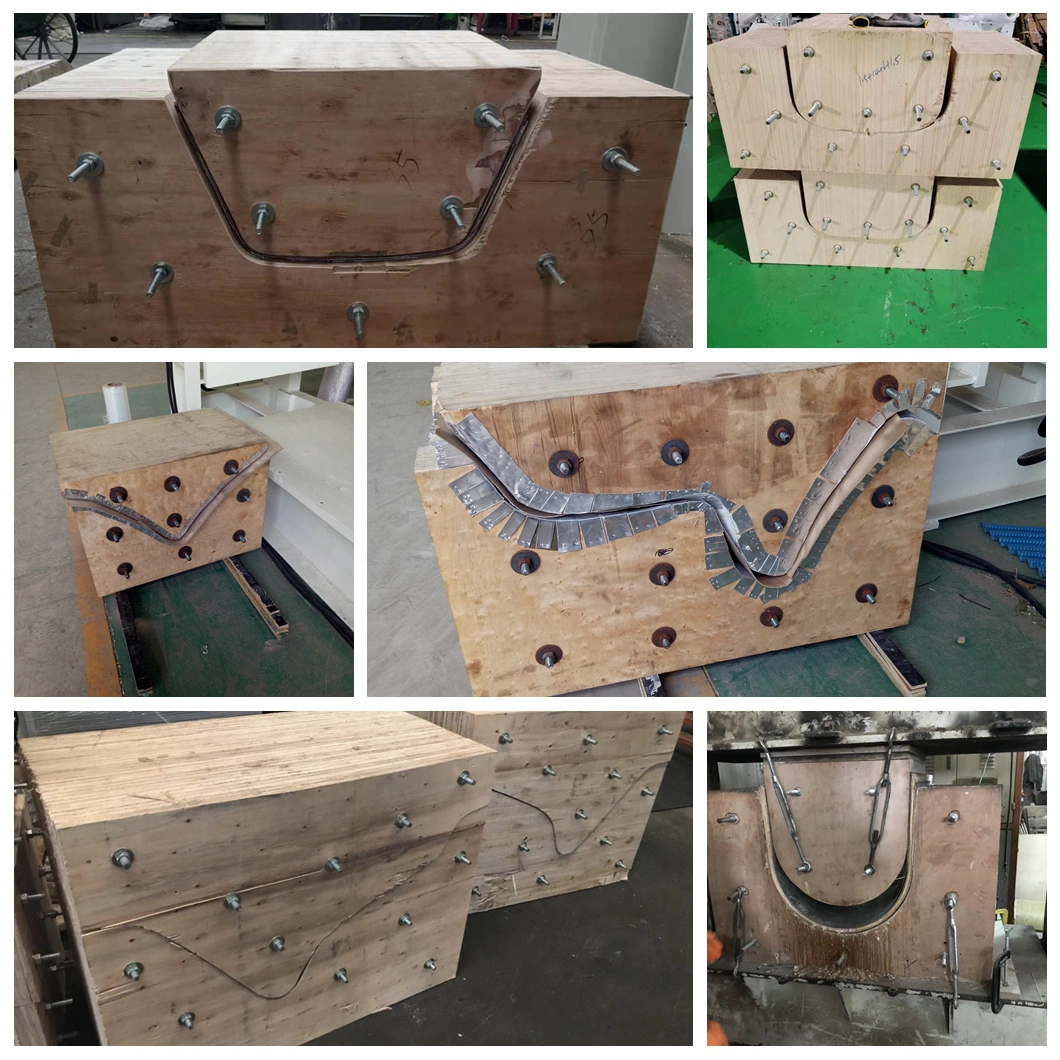

The Wooden Mold

High Frequency Generator

High frequency generator(Radio frequency generator) is a plant which can turn normal electric power to high frequency(electronic-magnetic) power, apply this power to the load equipment or electrode, the water or glue molecule with in the work pieces is polarized and rapidly change direction or move follow the frequency change of the electronic-magnetic power, thus cause suddenly friction, this friction between molecule makes the temperature raises, thus the water vaporized and glue bond. High frequency generator is suitable for curved plywood forming or wood panel jointing or hard wood drying, it is a core pant for high frequency machinery.

Power:50Hz, 3Phase 4Wire;Input Power: 30/40/70KVA; Output Power: 20/30/50KW; Oscillation:6.78MHz;Various Protections; Tuning Vacuum Capacitor; Forced wind cooling; 2output

1)High Frequency Oscillator (radio frequency generator, high frequency generator) is a plant which can turn normal electric power to high frequency(electromagnetic) power.

2) is suitable for fast curing of glue or water.

3)high Frequency Oscillator is suitable for curved plywood forming or wood panel jointing or hard wood drying.

4)t is a core plant for high frequency machinery.

Machine Details

Our Certificate

About Us

FAQ

1.How about the press table size?

Our standard size are 1600x800mm and 2500x1300mm.Customized size is also available.

2.What are included in 1 set machine?

The working type of the machine is "one drive two",that means one set HF generator drives two sets hydraulic press machine.

3.What is the material of the mold?

It is wood.

4.How long does it take to press one chair seat?

For standard small chair,it wil take around 3-4 minutes.

High frequency curved plywood press applies high frequency generator to hydraulic press, by mold and electro, it transfers the high frequency power to the work piece to achieve the function of fast gluing and forming. It's suitable for BENT PLYWOOD CHAIR, BENT OR ARC PLYWOOD FOR THE FURNITURE OR BED or other bent plywood products like CLOTH HANGER OR SURFACE OF MUSICAL INSTRUMENT.

Technicial Parameter

| Model | YX80-SA | YX150-SA |

| HF Generator | 20KW,2 OUTPUT | 30KW,2 OUTPUT |

| Oscillation | 6.78MHz | 6.78MHz |

| Cylinder | 80T,2PCS | 150T,2PCS |

| Strock of Cylinder | 600mm | 600mm |

| Press working size | 1600*800mm | 2500*1300mm |

| Power of Hydraulic | 7.5KW | 7.5KW |

| Opening of Plate | 1100mm | 1100mm |

| Packing | Foam and plastic | Foam and plastic |

| Delivery | 40 working days | 40 working days |

| Overall Size | 2300*800*2200mm | 2900*1300*2200mm |

| Gross Weight | 8T | 17T |

Actual Working

Application

Charactor of High Frequency Curved Plywood Press

A.Fast and uniformly heating

B.Bending shape is stable, not easy to change de-lamination.

C.High frequency power is a selectively heating power, it concentrates only on water or glue. wood cannot consume high frequency power, so it is effective and power saving.

D.Wooden or MDF mold used, much economic than metal mold if shape is frequency changed.

The Wooden Mold

High Frequency Generator

High frequency generator(Radio frequency generator) is a plant which can turn normal electric power to high frequency(electronic-magnetic) power, apply this power to the load equipment or electrode, the water or glue molecule with in the work pieces is polarized and rapidly change direction or move follow the frequency change of the electronic-magnetic power, thus cause suddenly friction, this friction between molecule makes the temperature raises, thus the water vaporized and glue bond. High frequency generator is suitable for curved plywood forming or wood panel jointing or hard wood drying, it is a core pant for high frequency machinery.

Power:50Hz, 3Phase 4Wire;Input Power: 30/40/70KVA; Output Power: 20/30/50KW; Oscillation:6.78MHz;Various Protections; Tuning Vacuum Capacitor; Forced wind cooling; 2output

1)High Frequency Oscillator (radio frequency generator, high frequency generator) is a plant which can turn normal electric power to high frequency(electromagnetic) power.

2) is suitable for fast curing of glue or water.

3)high Frequency Oscillator is suitable for curved plywood forming or wood panel jointing or hard wood drying.

4)t is a core plant for high frequency machinery.

Machine Details

Our Certificate

About Us

FAQ

1.How about the press table size?

Our standard size are 1600x800mm and 2500x1300mm.Customized size is also available.

2.What are included in 1 set machine?

The working type of the machine is "one drive two",that means one set HF generator drives two sets hydraulic press machine.

3.What is the material of the mold?

It is wood.

4.How long does it take to press one chair seat?

For standard small chair,it wil take around 3-4 minutes.