Basic Info.

Packaging & Delivery

Product Description

Good Quality 3D Hydraulic CNC Full Automatic Pipe Bending Machine

Characters:

1. Operate by NC control unit, imported electric and hydraulic elements.

2. English showing and conversational operation.

3. It can adjust speed in each bend and the bending precision is high

4. Suitable Materials: Steel pipe, stainless steel pipe, copper pipe, aluminum pipe and others.

Technical parameters

| Specification/Model | Unit | Remark | |

| Max bending capability(OD) | mm | Φ50 | 1. The Minimum bending diameter based on the pipe diameter 2.The Max bending diameter can according to the customer's requirement 3.The Max length of mandrel can according to customer's requirement |

| Max bending radius | mm | R350 | |

| Min bending radius | mm | According to the pipe diameter | |

| Max bending angle | Degree | 190 | |

| Max effective distance of mandrel | mm | 2200 | |

| Control System | NC Control | ||

| Max elbow bend pipe | Unit | 16 | |

| Max storable sections | Unit | 16×16 | |

| Motor power | KW | 5.5 | |

| Max. Hydraulic Pressure | Mpa | 12 | |

| Hydraulic System Control | Electromagnetic Valve | ||

| Oil Tank Capacity | L | 220 | |

| Measurement | mm | 3000×700×1030 | |

| Weight of Machine | Kg | 1220 |

Terms of trade

1. Minimum order quantity (MOQ): 1 piece

2. Delivery time: about 40 workdays

3. Port of loading: port of Tianjin

4. Type of payment: by T/T or by L/C

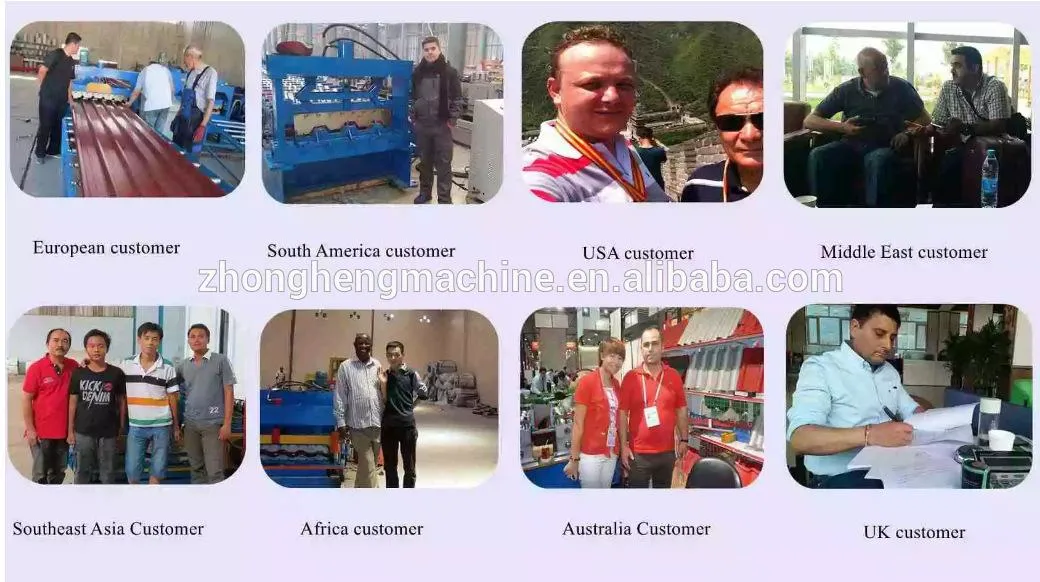

Company

FAQ

Q: Are you a trading company or a factory?

A: We are factory with professional production team and service consciousness just for exporting various types of cold roll forming machines.

Q: Can a machine produce only one style panel profile?

A: Not complete. Suitable for wider and double layer manufacturing machines. It can produce more than 3 panels.

Q: Is there quality control when producing the production line?

A: Yes, we have a team that is responsible for quality control, including the laying of raw materials, processing rolls and other parts, processing, assembly, testing and packaging on the roll surface and shaft.

Q: What can you do if the machine broken?

A: Our machine is warranted for 24 months. If the damaged part cannot be repaired, we can send a new part to replace the damaged part, but you will need to pay the courier fee yourself. If the warranty period is exceeded, we can resolve the issue through negotiation and we provide technical support for the entire life cycle of the device.

Q: What is your strength compared to other suppliers?

A: We will give you the best service. We will provide you with good advice that exceeds your requirements. These lines are easy to install and have low maintenance requirements.

Q: Can we become your agent abroad?

A: Of course, if you have a business in the rolling forming line, we will welcome a lot of cooperation

Contact of Sunny