Basic Info.

Model NO.

LHA-1400PC

Origin

China

HS Code

8462230000

Product Description

Equipment Outlook

Technical parametres

Main components brand&specification

Certification

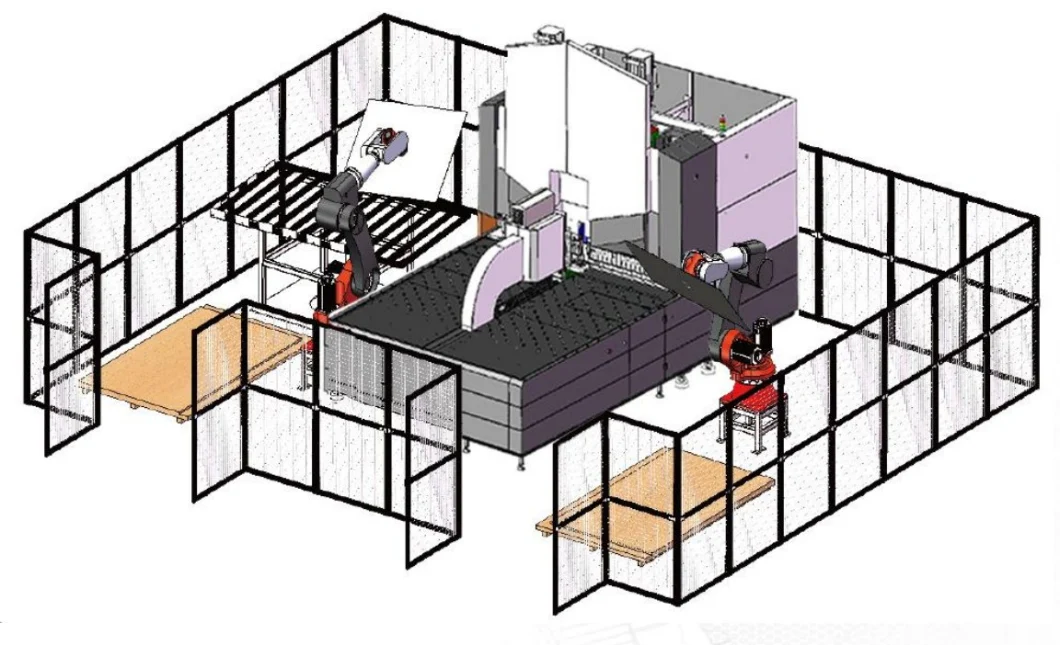

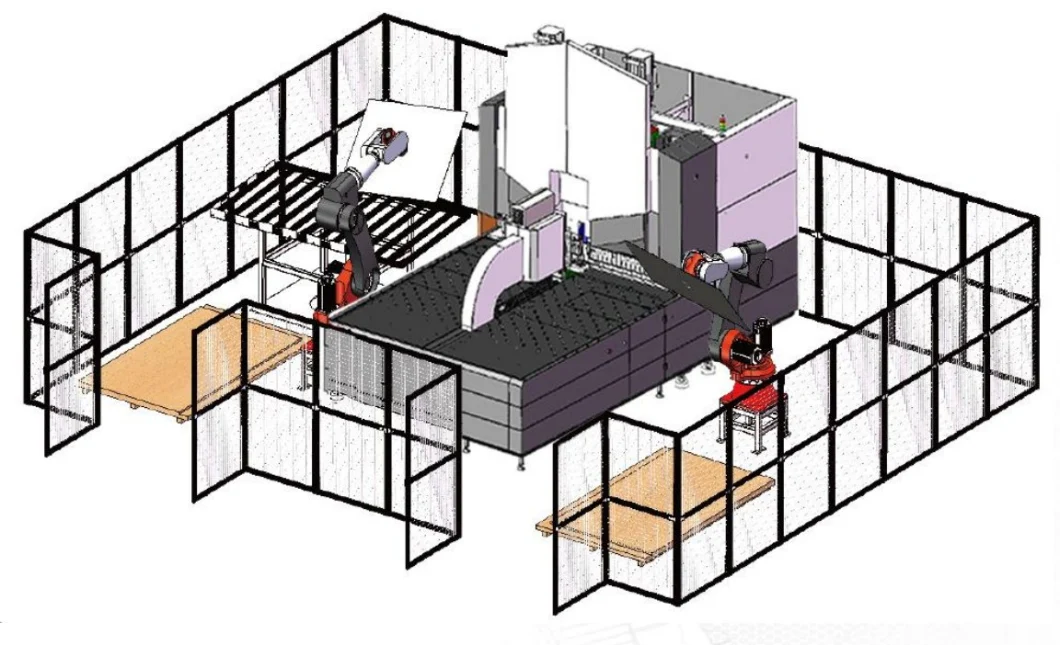

Automation combination with robot arm

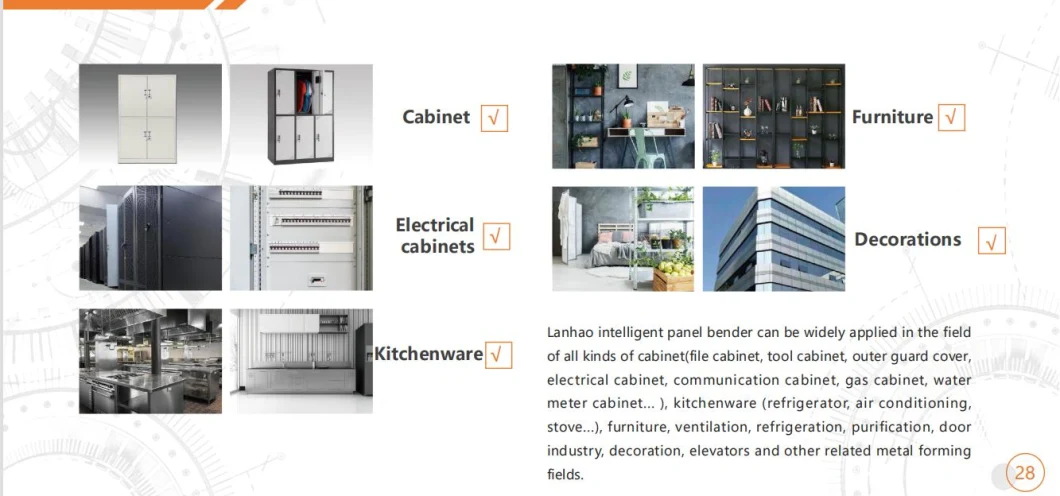

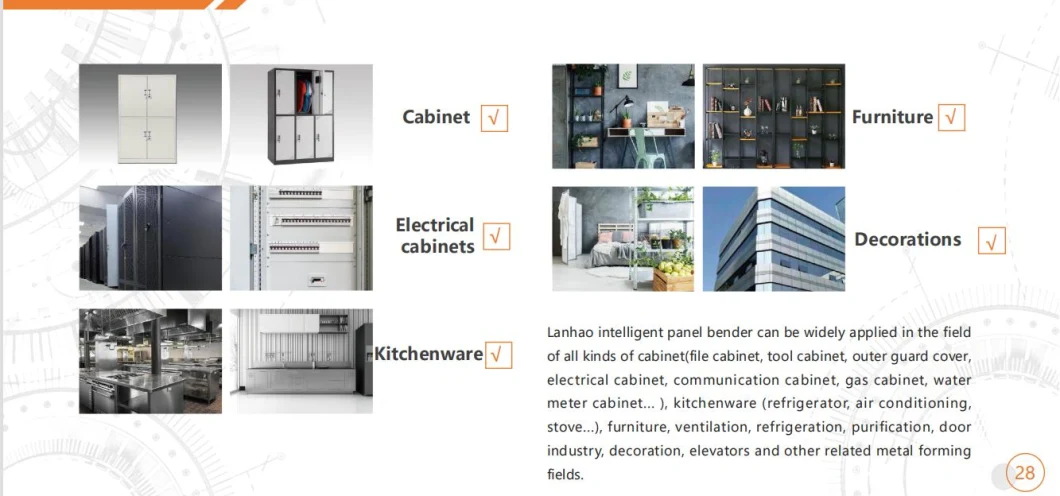

Application:

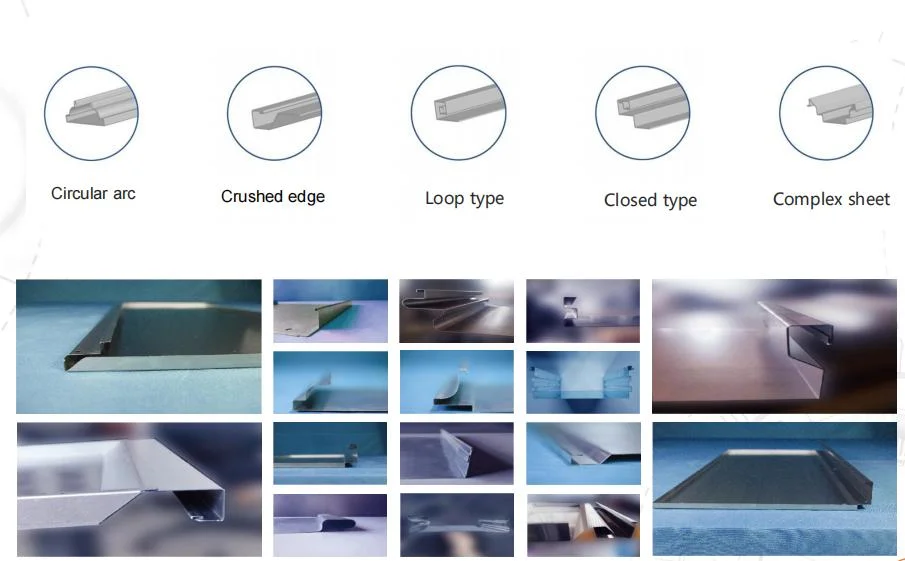

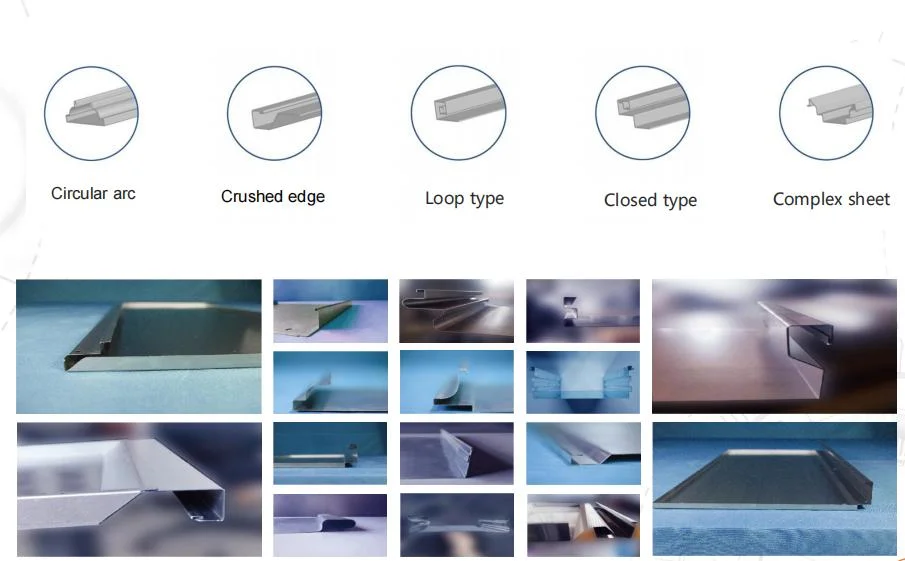

Bending shapes:

Technical parametres

| LHA-1400PC-03 Technical parameters | |

| Feeding structure | Pressing arm |

| Work table structure | brush |

| System minimum accuracy | 0.001mm |

| Max bending speed | 0.2 second/time |

| Max feeding speed | 90m/min |

| Max.bending width | 1400mm |

| Max.Bending size | L 1400mm X W 1400mm |

| Max. Bending height (The maximum bending height after customization can reach 300mm) | 170mm 300mm(customizable) |

| Min. Bending height | 3mm |

| Min.arc radius | 0.5mm |

| Rated power | 380V |

| Motor power | 40KW |

| Average power | About 1.9KW |

| Noise | About 50 dB |

| Machine size | L440cm X W190cm X H290cm |

| Total weight | About 12 tons |

| User operating environment | Win7 or above system |

| Max. Bending width | UTS 515N/mm2 304 stainless steel 1.5mm UTS 410N/mm2 cold panel 2.0 mm UTS 265N/mm2 aluminum panel 3.0mm |

| Min. Panel width | 0.35mm |

| Four side forming min. Inner size | About 140mmx190mm( excluding inverted folded side) |

| Double side forming min. Inner size | About 140mm |

| Bending angle | 0-180 degree |

| Axis | 15 |

Main components brand&specification

| Description | Supplier brand | Description |

| Operation environment | Lanhao Intelligent | Win7or above/LINUX |

| CNC Control system | Lanhao Intelligent | Lanhao independently developed a multi-axis concurrent linkage CNC system. It precisely realizes the perfect matching of concurrent linkage of all axes of the equipment, the movement runs naturally and smoothly, and the comprehensive speed reaches the highest efficiency in the industry. It perfectly realizes the acceleration and deceleration control, which minimizes the vibration of the machine and greatly prolongs the life of the parts. The hardware circuit board is independently designed with lead-free soldering and surface immersion gold treatment. |

| servo motor | Joint R&D | Joint R&D of full closed-loop system, perfect match with Lanhao control system, the highest efficiency in the industry. |

| Screw rod | Nanjing Technical Equipment | The domestic top screw manufacturer Nanjing Technology 6320 heavy-duty grinding grade screw has more stable transmission and higher precision. |

| Bearing | NACHI | Japan NACHI original high-load ball screw injection molding machine special bearing 60TAF13X, the bearing ball diameter is up to 16mm, and each axis has 12 bearings. |

| Line rail | Nanjing Technical Equipment | Nanjing Technical heavy-duty high-precision P3-level 45 roller-type linear guide has greater bearing capacity and higher precision. |

| Lathe bed | Lanhao Intelligent | Lanhao independently designed the high-grade casting body, using high-grade QT500-7 and gray iron 250 castings to effectively ensure the stability under high tonnage impact force |

| Tools | Lanhao Intelligent | Lanhao's patented tool, with carburizing treatment process, high-frequency quenching and overall quenching and tempering, More wear-resistant, longer service life |

| Reducer | Joint R&D | Adopt high-precision helical gear planetary reducer, with stronger carrying capacity |

| Coupling | TECMEN | Sino-German joint venture brand |

| Oil system | Taiwan Yuxiang | Taiwan brand |

Certification

Automation combination with robot arm

Application:

Bending shapes: