Basic Info.

Model NO.

YL

Warranty

12 Months

Applicable Pipe Size

20mm-250mm

Design Technology

European Customer Support Technology

Advantages

Long Life/High Efficiency/High Capacity

Extruder Control

by Siemens PLC Screen Touch

Electrical Components

Siemens, ABB, Omron, FUJI, etc.

Production Speed

70-120PCS /Hour

Delivery Time

Around 40 Days

Motor Brand

Siemens

Shipment

LCL and FCL

Machine Installation

Available

Motor Drive/Inverter

Siemens/ABB Brand

Keywords

Plastic Bending Machine

Certification

CE, ISO9001:2008, SGS , Ukca

Customized

Customized

Pipe Material

PVC

Transport Package

Plastic Film and Wooden Pallet

Specification

4m*4m*3m

Trademark

YILI

Origin

Zhangjiagang, China

HS Code

84778000

Production Capacity

30 Sets/Per Month

Packaging & Delivery

Package Size

600.00cm * 200.00cm * 200.00cm

Package Gross Weight

50000.000kg

Product Description

Introduction

Yili owns the most sophisticated team and top class R&D experts from the industry. Our PVC duct and PVC pipe Bending machines are used to produce PVC pipe or PVC duct bends with socket. Thanks to technical support from our customers in Italy and Germany, we can manufacture the machines with different requirements on basis of their many years' experience. Our bending machines become the most affordable and economical bending machine in the world. Our bending machines already have CE and UKCA certificate.

Technical Specification

Tech Features & Advantages

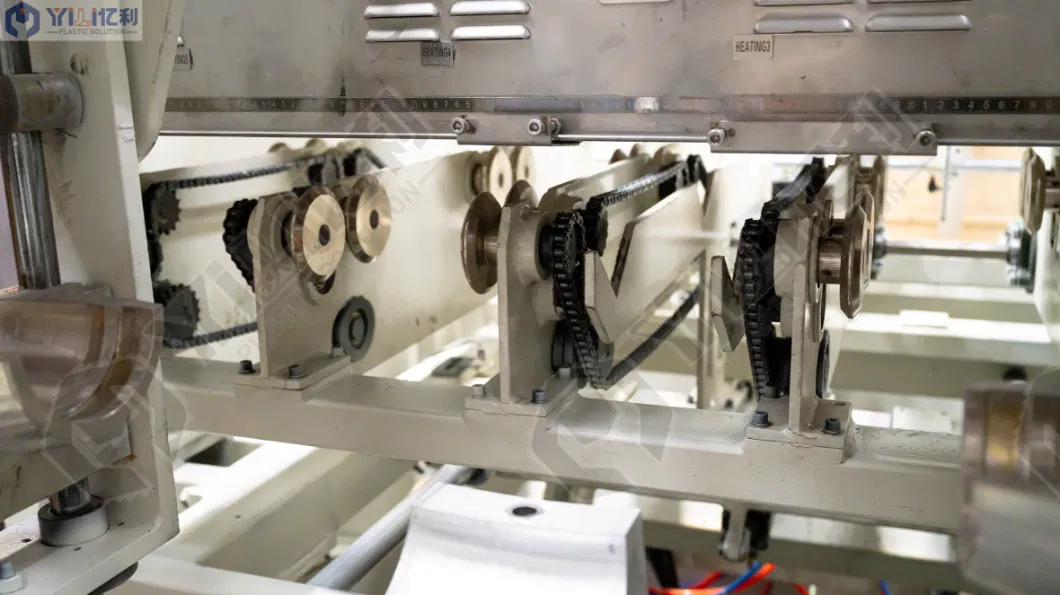

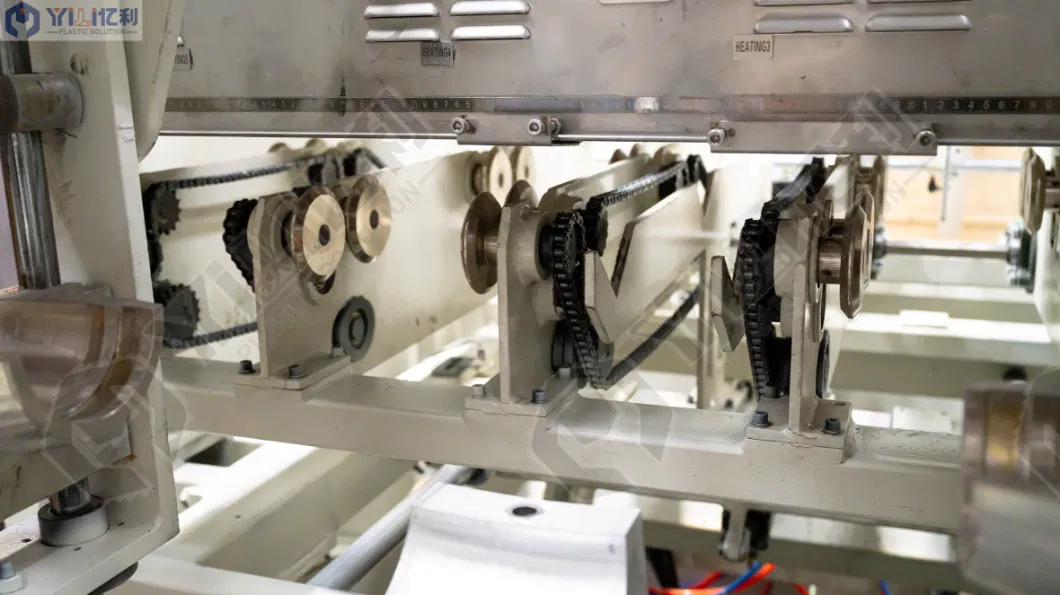

Heaters made in Ireland, can heat up to 700ºC with insulated SUS304 cover. Two heating steps ensure efficient and stable heating for the pipes. The height of the heating device can be adjusted, so that it can be applied to PVC pipes of different diameters.

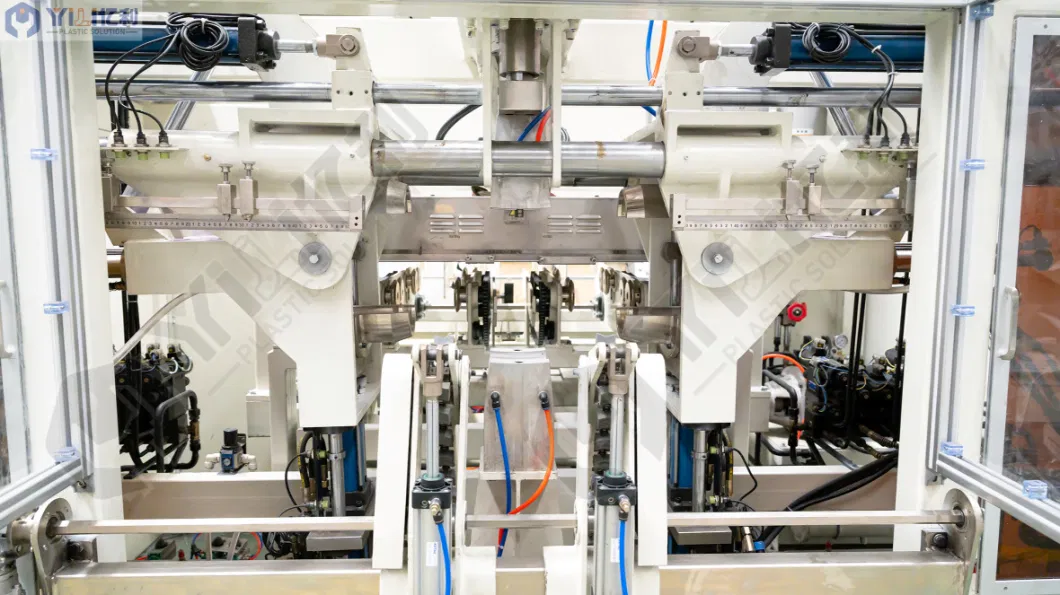

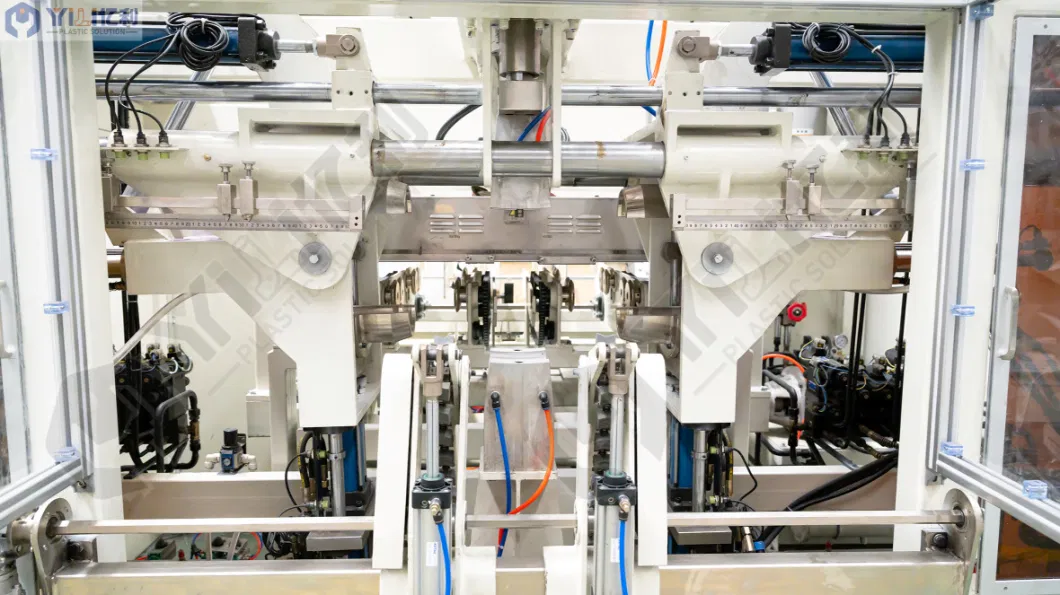

This automatic pipe bending machine has a compact structure, integrates pipeline transportation, heating, belling, pipe bending and pipe outlet together with full automation. Compared with manual machines, the production efficiency of this machine is increased by 3-5 times.

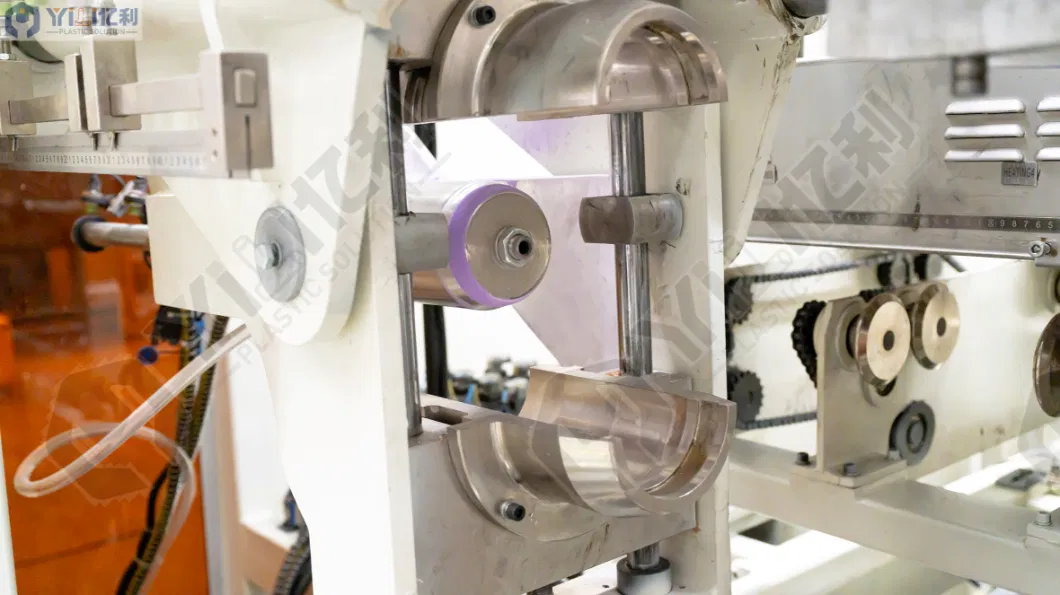

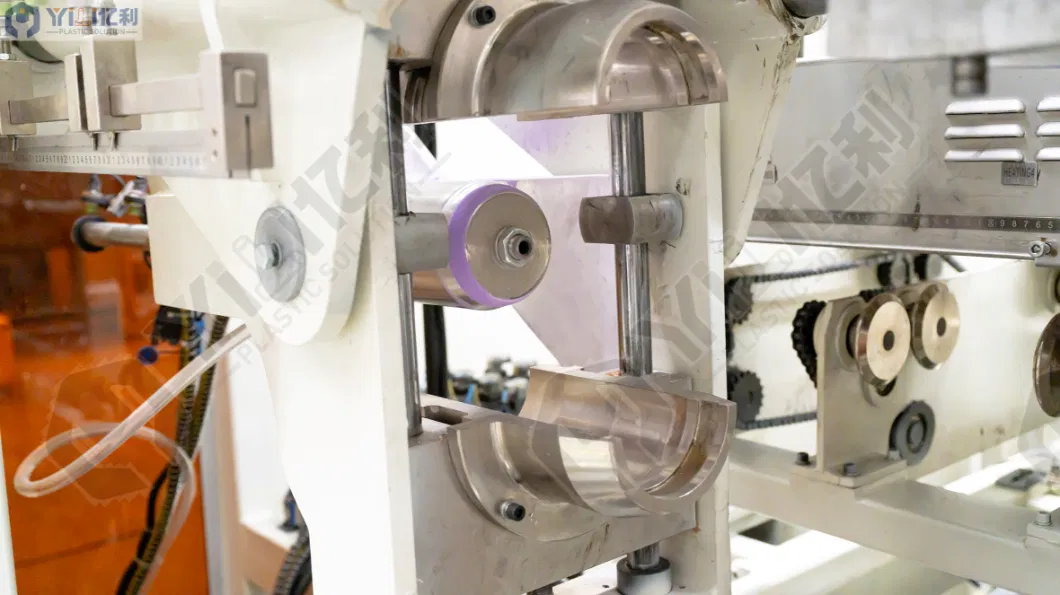

At the front bending, it is installed high-quality belling mold and clamping tool with 45# nickel-phosphorus treatment, and imported photoelectric Autonics detection, to ensure accurate belling length and beautiful appearance of the belling.

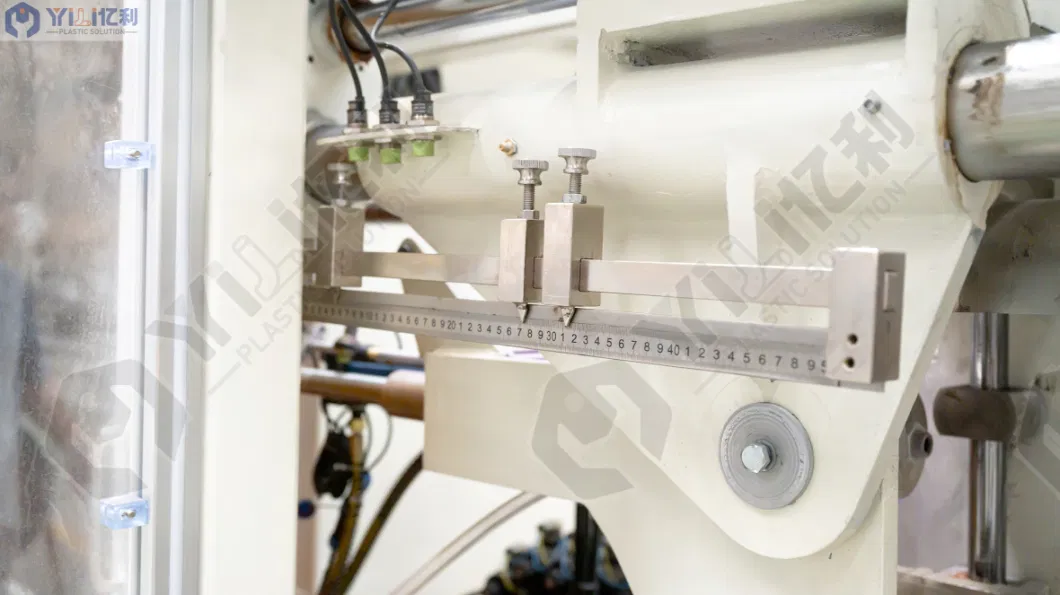

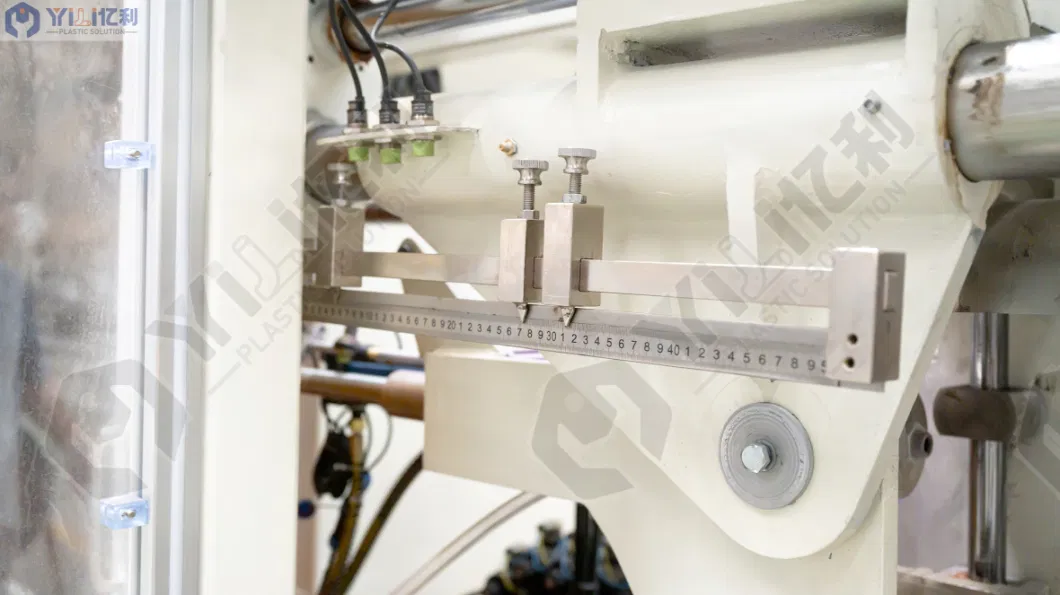

A scale is installed for adjusting belling and bending mold base, which ensure that the tolorance of each product is within 1 mm.

After the automatic discharge device receives the signal, it will automatically lift , take the product and send out. No need to use labors, efficient and safe.

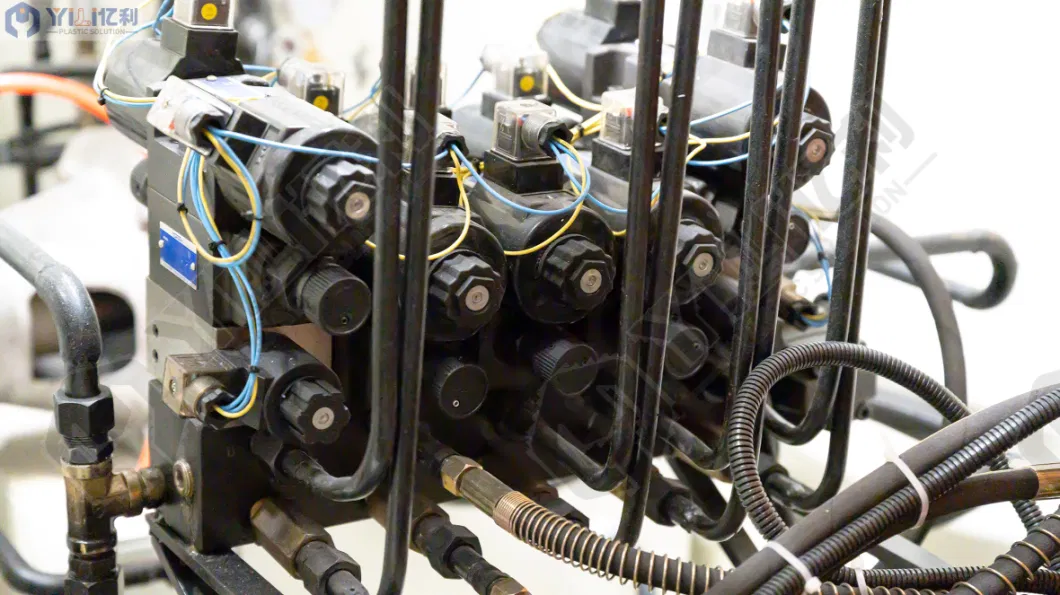

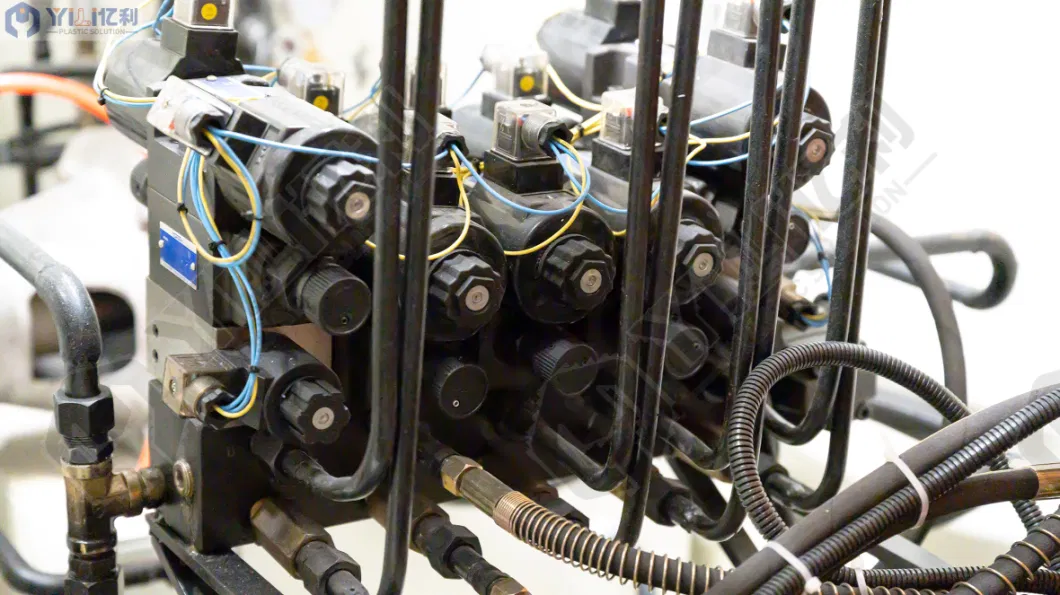

Advanced hydraulic system adopts Japanese YUKEN brand oil pump and hydraulic solenoid valve, high-quality energy storage system to ensure energy saving and noise reduction.

Sample bending pipes

Yili owns the most sophisticated team and top class R&D experts from the industry. Our PVC duct and PVC pipe Bending machines are used to produce PVC pipe or PVC duct bends with socket. Thanks to technical support from our customers in Italy and Germany, we can manufacture the machines with different requirements on basis of their many years' experience. Our bending machines become the most affordable and economical bending machine in the world. Our bending machines already have CE and UKCA certificate.

Technical Specification

| Model | Pipe OD (mm) | Bending angle | Capacity (pcs/hr) |

| YL-63 | Φ20-63 | 11.25/22.5/45/90 degrees or custom made | 480 |

| YL-110 | Φ50-110 | 11.25/22.5/45/90 degrees or custom made | 80 |

| YL-160 | Φ75-160 | 11.25/22.5/45/90 degrees or custom made | 80 |

| YL-250 | Φ90-250 | 11.25/22.5/45/90 degrees or custom made | 72 |

Tech Features & Advantages

- Wide range of machines for bending and socketing of PVC pipes, diameter min. 20mm - max. 250mm;

- Variable angle, radius and length; machine and forming molds are designed on basis of bending sizes;

- Production capacity (circle time) same as European machines;

- Energy saving 60% compare with manual bending machine;

- Hydraulic parts use Yuken brand made in Japan;

- Ceramic heaters made in Ireland afford temperature up to 700ºC;

- Program is improved through 5 years' experience. Use Siemens touch screen, with remote control function.

Heaters made in Ireland, can heat up to 700ºC with insulated SUS304 cover. Two heating steps ensure efficient and stable heating for the pipes. The height of the heating device can be adjusted, so that it can be applied to PVC pipes of different diameters.

This automatic pipe bending machine has a compact structure, integrates pipeline transportation, heating, belling, pipe bending and pipe outlet together with full automation. Compared with manual machines, the production efficiency of this machine is increased by 3-5 times.

At the front bending, it is installed high-quality belling mold and clamping tool with 45# nickel-phosphorus treatment, and imported photoelectric Autonics detection, to ensure accurate belling length and beautiful appearance of the belling.

A scale is installed for adjusting belling and bending mold base, which ensure that the tolorance of each product is within 1 mm.

After the automatic discharge device receives the signal, it will automatically lift , take the product and send out. No need to use labors, efficient and safe.

Advanced hydraulic system adopts Japanese YUKEN brand oil pump and hydraulic solenoid valve, high-quality energy storage system to ensure energy saving and noise reduction.

Sample bending pipes