Basic Info.

Model NO.

YWB 1600T/8000

Type

Cnc Bending Machine

Hydraulic Valve

Hawe Germany

Oil Pump

Hawe Germany

Oil Filter

Hydac Germany

Oil Seal

Nok Japan

CNC Control

Delem Holland or Cybelec Swiss

Servo Motor and Driver

Yaskawa or Panasonic Japan

Ball Screw

Hiwin Taiwan

Linear Scale

Opkon Turkey

Transport Package

Plastic Film

Specification

4500*2000*2670

Trademark

AHYW

Origin

China

HS Code

8462219000

Production Capacity

1000 Sets/Year

Product Description

ANHUI YAWEI 1000T6000 LARGE HEAVY DUTY CNC PRESS BRAKE

Product Description

AHYW CNC Press Brakes 1000T6000mm is fully synchro electro hydraulic cnc press brakes design, with Y1&Y2 cylinders mounted on two sides of side frames, it have two independent linear scale monitor the position of each cylinder, which is also controlled by DELEM CNC Press brake controller, like DA58T, DA66T touch screen controller.

This heavy duty AHYW CNC Press Brake can bending 25mm mild steel&carbon steel plate, 12mm stainless steel plate bending, with Max 6m&20ft metal plate bending capacity.

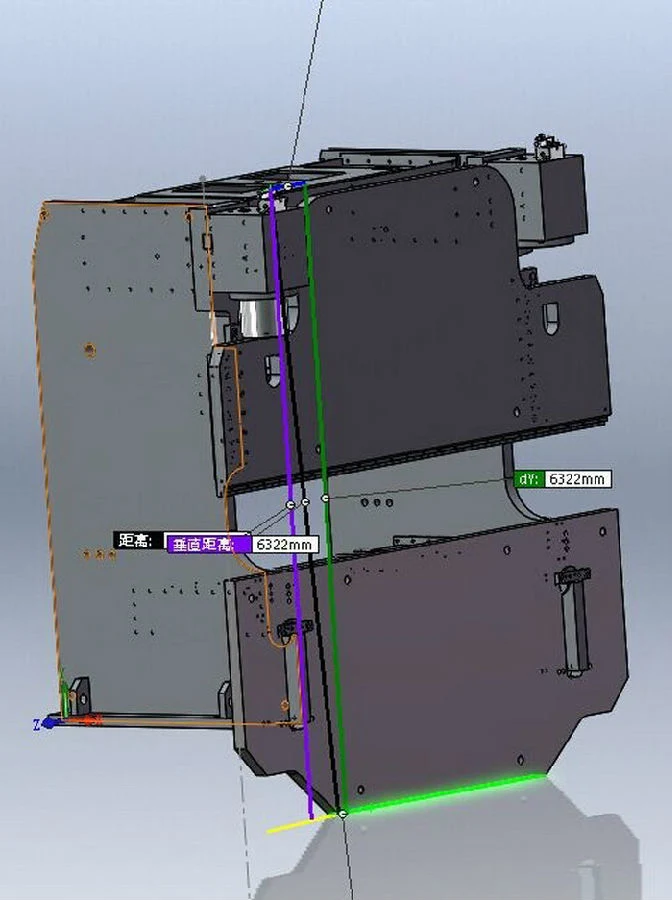

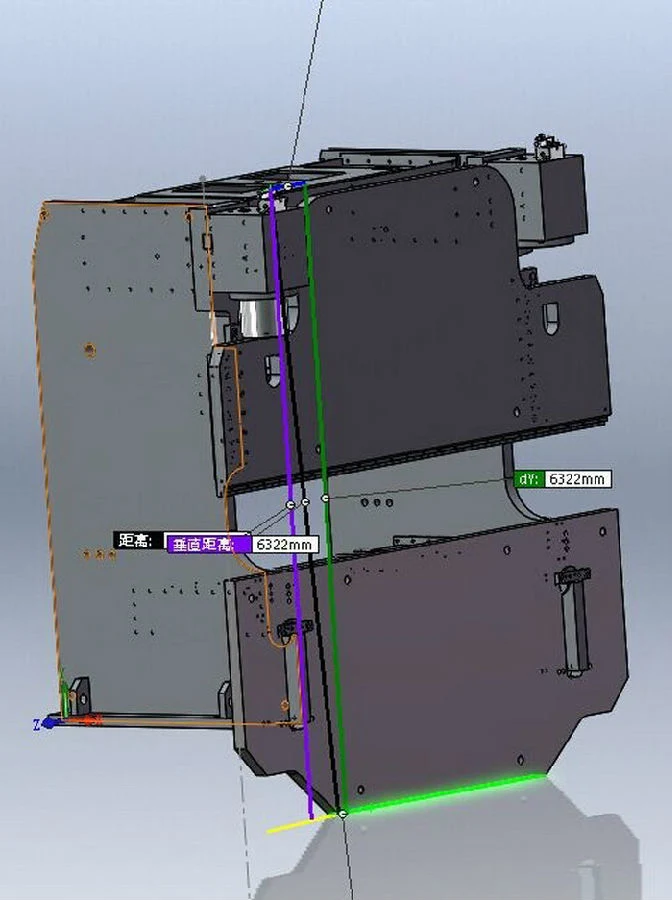

Main features• CNC Press Brakes is overall welded and designed using SOLID WORKS 3D programming.

• Linear encoders are applied to the bending machine to measure ram position. The encoders are connected to the table of the press brakes in such a way that deformation of the side frames during bending does not influence the accuracy of the upper beam position.

• Heavy Duty Bending capacity design, the main frame made of steel welded constructions,has been designed according minimum stretch and optimum resistance standards.

• The Y1 and Y2 axes operate as independent double acting hydraulic systems. Both axis share the same oil supply, but the flow to the valves as well as true positions of the ram are entirely and separately controlled by CNC press brake controller.

Two linear encoders (Y1-Y2) are mounted on two sides of the bending machine. They are used to measure the exact distance between the ram and worktable. The encoders are connected to the press brake table so that the deformation of the side frames does not influence the position. The position data is immediately sent to the control system for calculation and then the output will be turned into control signal and sent to the servo valves (S1-S2). If there is any error, two servo calves will be quickly rectified by CNC system. It always ensures the balance between the ram and worktable.

•Using CNC boring&milling machine to fabricate the main parts, like cylinder connecting board, working table cylinders, processed as precision from solid full material and made honed;Pistons, processed from forged steel, hardened,grinding is done, and chrome-coated.

• Heavy Duty CNC controlled back gauge with Servo motor and drive, ball screw and linear guide.

• Re-assemble Large 6m Bending Machine Design.

• DELEM Large Automatic CNC Press Brakes.

•Using CNC boring&milling machine to fabricate the main parts, like cylinder connecting board, working table cylinders, processed as precision from solid full material and made honed;Pistons, processed from forged steel, hardened,grinding is done, and chrome-coated.

• Heavy Duty CNC controlled back gauge with Servo motor and drive, ball screw and linear guide.

• Re-assemble Large 6m Bending Machine Design.

• DELEM Large Automatic CNC Press Brakes.

Solid Works 3D Design for 6m Large CNC Press Brakes

YWB series cnc press brake features a rigid frame for minimum deflection under the load. Machine welding is made by welding aparatus & welding robots. After the welding,we make stress relief process by vibration system. After the stress relief process machine frame goes to CNC 5 axes machining centers for accuracy. All referance surfaces and connection holes are machined. By all this processes machine frame sensivity is protected for a long life time.

DA53T CNC System

* "Hot-Key" touch navigation

* 10.1″ high-resolution color TFT

* Up to 4 axes (Y1, Y2 + 2 aux. axes)

* Crowning control

* Tool/material / product library

* Servo and frequency inverter control

* Advanced Y-axis control algorithms for closed-loop as well as open-loop valves

* TandemLink (option)

* USB memory stick interfacing

* Profile-T offline software

Detailed Photos

Technical Parameters

| Parameter | Unit | YWB-1000t/6100 |

| Bending Power | Ton | 1000 |

| Bending Length | mm | 6100 |

| Max. Bending Plate Thickness | mm | 25 |

| Distance Between Columns | mm | 4600 |

| Slider Stroke | mm | 400 |

| Max. Ram Daylight Opening | mm | 1000 |

| Throat Depth | mm | 600 |

| X Back Gauge Stroke | mm | 1200 |

| Main Motor Power | kw | 75 |

| Gross Weight | kg | 90000 |

| Dimensions(L*W*H) | mm | 6500*3200*5400 |

Company Profile

Anhui Yawei Machine Tool Manufacturing Co.,ltd. was founded in 2005, the registered capital is 81.88 million, with 120 employee, floor space about 40000 square meters, the location is close to Nanjing Airport and near to Shanghai city.

Anhui Yawei Machine Tool Manufacturing Co.,ltd. was founded in 2005, the registered capital is 81.88 million, with 120 employee, floor space about 40000 square meters, the location is close to Nanjing Airport and near to Shanghai city.We specializes in exporting CNC Hydraulic Press Brake Machine, Hydraulic Shearing machine, CNC Fiber Laser Cutting Machine, CNC Robotic Arm, with over 120 different types. Our machines, which adopt advanced technology, have a high quality. The main electrical parts, hydraulic parts and the instrument of our machines are adopted the best products made by the famous manufacturer in the world.

We have passed ISO9001 quality system certification and the European Union CE certification, etc., at the same time established a perfect market service system and the system of the mature. Based on the good quality and top technology on our machines, we sell well in various countries and regions over 90 in the world such as U.S.A, Canada, Europe, South American, Middle East, and Southeast Asia market. The history of our independent Import and Export experience is more than 15 years.

We also make OEM machines for our European Agent, all of the configuration on the machines will according European standard and approved by customer satisfied. Advanced technologies, scientific management, wonderful products and approving service are kept on which we aim at.

We want to cooperate with you to promote our sales and build a long term cooperation with you for future business.

Best wishes for you and hope a better tomorrow for all of us!

Facilities & Equipment

Customer Photo

Certification

Service

Pre-Sales Service Technical and Sales team work After-Sales Service Engineers and Sales cooperate

• Inquiry and consulting support. • Training how to install the machine, and how to use• Suggest solution. the machine.

• View our Factory. • Engineers available to service machinery overseas.

FAQ

Q1. Are you a factory or a trading company?

A: Anhui Yawei Machine Tool Manufacturing Co, Ltd is a professional manufacturer of press brake, shearing machine, fiber laser cutting machine and other sheet metal processing equipment. We have more than 15 years of manufacturing experience, and our products were exported to more than 90 countries and regions.

Q2. This is the first time I use this kind of machine, is it easy to operate?

A: Detailed installation and operation instructions are sent to you free together with the machine. Free training courses are offered in our factory. Engineers are available to serve overseas but all the expense needs being paid by your side. Video technical support and online support are provided, 24 hours technical support by calling, video and email.

Q3. What is your normal lead-time??

A: Lead-time for a routine order would typically be 25-30 days. However, this varies with a number of factors including order size, machine model, workpiece complexity and shop load, to mention a few. Lead times are provided with all quotations. Please advise us if a rush order is required and we can usually accommodate.

Q4. Where are you located? How do I get there?

A: Anhui Yawei Machine Tool Manufacturing Co, Ltd is located in Maanshan city, Anhui Province, China; near Nanjing and Shanghai.

You can fly to Nanjing airport or Shanghai Hongqiao airport, or take high-speed rail to Nanjing South Railway Station, then we will pick you up.

A: Anhui Yawei Machine Tool Manufacturing Co, Ltd is a professional manufacturer of press brake, shearing machine, fiber laser cutting machine and other sheet metal processing equipment. We have more than 15 years of manufacturing experience, and our products were exported to more than 90 countries and regions.

Q2. This is the first time I use this kind of machine, is it easy to operate?

A: Detailed installation and operation instructions are sent to you free together with the machine. Free training courses are offered in our factory. Engineers are available to serve overseas but all the expense needs being paid by your side. Video technical support and online support are provided, 24 hours technical support by calling, video and email.

Q3. What is your normal lead-time??

A: Lead-time for a routine order would typically be 25-30 days. However, this varies with a number of factors including order size, machine model, workpiece complexity and shop load, to mention a few. Lead times are provided with all quotations. Please advise us if a rush order is required and we can usually accommodate.

Q4. Where are you located? How do I get there?

A: Anhui Yawei Machine Tool Manufacturing Co, Ltd is located in Maanshan city, Anhui Province, China; near Nanjing and Shanghai.

You can fly to Nanjing airport or Shanghai Hongqiao airport, or take high-speed rail to Nanjing South Railway Station, then we will pick you up.