Basic Info.

Model NO.

WC67K-200/3200

Type

Press Brake

CNC system

E200 or E21

Rated pressure

2000kn

working table length

3200mm

Transport Package

Plastic Covering

Specification

200T/3200mm

Trademark

HAVEN

Origin

China

HS Code

8462

Production Capacity

30unit/Month

Product Description

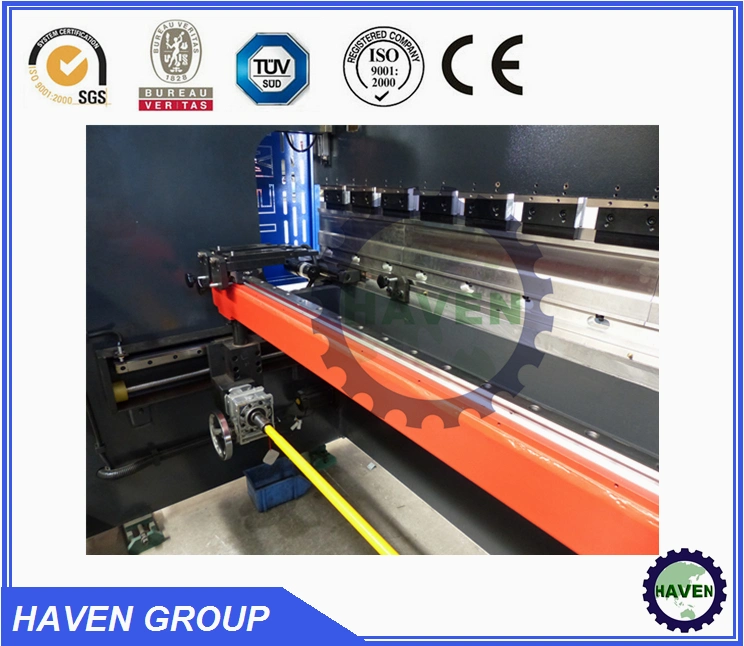

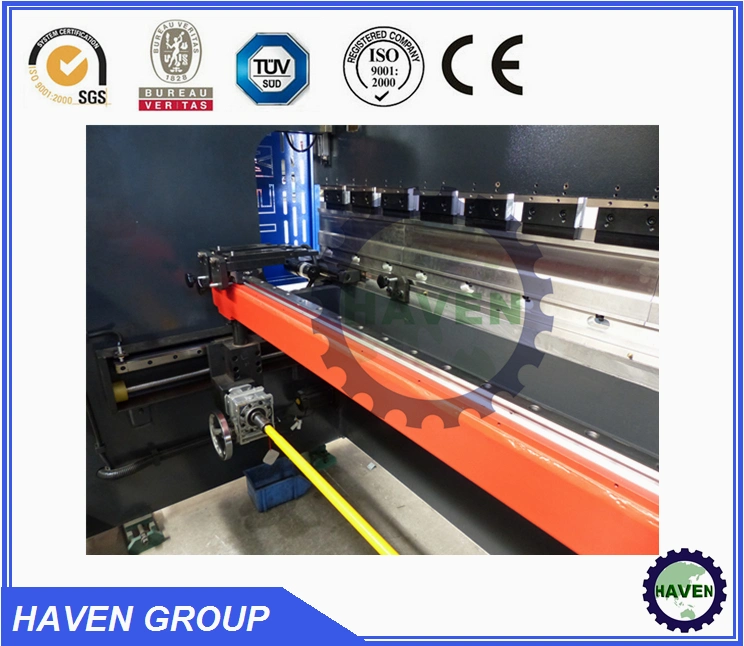

CNC Hydraulic Press Brake Bending Machine WC67K-200/3200

Main features:

1. The whole machine is in sheet plate welded structure, which internal stress eliminated by vibration aging technology, high strength and good rigidity of machine.

2. Double hydraulic oil cylinder is applied for upper transmission, provided with mechanical limit stopper and synchronous torsion bar, stable and reliable operation, as well as high precision.

3. Electrical adjustment and manual fine-tuning adjustment mode are adopted for distance of rear stopper and stroke of gliding block, and fitted with digital display device, easy and quick in use.

4. Upper clamp is fitted with compensation device.

5. Worktable mechanical compensation or hydraulic compensation device is optional.

Main specification:

Detailed photos:

CNC system E200 main completed:

* E200 CNC system control 2 axis --- (1) Backgauge distance (2) Ram stroke;

* ball lead screw and servo motor for back guage;

* Main electric components SIEMENS or SCHNEIDER brand;

* Main motor SIEMENS BEIDE brand;

* hydraulic pump is from America brand SUNNY;

* Hydraulic Seal Rings Are From Japan brand NOK;

* Hydraulic valve is America brand OMEGA;

* Electrical Control Box;

* Motorized Back Gauge;

* Pedal Control Switch;

* Standard Punch and Die;

* Back and side safety curtain;

* Foundation Bolts ;

* English Manual;

CNC system E21 main completed:

* with inverter and lead screw for back gauge;

* Main electric components SIEMENS or SCHNEIDER brand ;

* Main motor SIEMENS BEIDE brand;

* hydraulic pump is SUNNY brand (USA);

* Hydraulic Seal Rings Are From Japan, NOK brand;

* Hydraulic valve is from OMEGA brand (USA);

* E21 swing type Control Panel;

* Electrical Control Box;

* Motorized Back Gauge and Pedal Control Switch ;

* Front support arms;

* Standard Punch and Die (fixed on the machine);

* Back and side safety curtain;

* Foundation Bolts;

* English Manual ;

Main features:

1. The whole machine is in sheet plate welded structure, which internal stress eliminated by vibration aging technology, high strength and good rigidity of machine.

2. Double hydraulic oil cylinder is applied for upper transmission, provided with mechanical limit stopper and synchronous torsion bar, stable and reliable operation, as well as high precision.

3. Electrical adjustment and manual fine-tuning adjustment mode are adopted for distance of rear stopper and stroke of gliding block, and fitted with digital display device, easy and quick in use.

4. Upper clamp is fitted with compensation device.

5. Worktable mechanical compensation or hydraulic compensation device is optional.

Main specification:

| model | pressure (kn) | Working table length (mm) | Distance between housing | Throat depth (mm) | RAM travel (mm) | Max. open height | Adjust- ment of RAM travel (mm) | Working table Height (mm) | Main motor | Machine overall Dimension (mm) L x W x H | |

| Power (kw) | Speed (mm/s) | ||||||||||

| 30X1300 | 300 | 1300 | 1110 | 200 | 40 | 275 | 80 | 710 | 3 | 1440 | 1800X1550X1900 |

| 30X1600 | 300 | 1600 | 1225 | 200 | 40 | 275 | 80 | 710 | 3 | 1440 | 1950X1550X1900 |

| 40X1300 | 400 | 1300 | 1080 | 200 | 100 | 275 | 80 | 710 | 4 | 1440 | 1950X1550X1990 |

| 40X1600 | 400 | 1600 | 1200 | 200 | 100 | 320 | 80 | 710 | 4 | 1440 | 1950X1550X1900 |

| 40X2000 | 400 | 2000 | 1500 | 220 | 100 | 320 | 80 | 730 | 4 | 1440 | 2150X1600X1980 |

| 40X2200 | 400 | 2200 | 1500 | 220 | 100 | 320 | 80 | 740 | 4 | 1440 | 2250X1700X1950 |

| 40X2500 | 400 | 2500 | 2000 | 220 | 100 | 320 | 80 | 730 | 4 | 1440 | 2505X1125X2000 |

| 50X2500 | 500 | 2500 | 1900 | 250 | 120 | 300 | 120 | 750 | 5.5 | 1440 | 2570X1270X1800 |

| 50X3200 | 500 | 3200 | 2600 | 250 | 120 | 300 | 120 | 750 | 5.5 | 1440 | 3270X1350X1960 |

| 63X2000 | 630 | 2000 | 1500 | 250 | 100 | 360 | 100 | 770 | 5.5 | 960 | 2060X1725X2280 |

| 63X2500 | 630 | 2500 | 2050 | 250 | 100 | 360 | 100 | 770 | 5.5 | 960 | 2560X1725X2280 |

| 63X3200 | 630 | 3200 | 2600 | 250 | 100 | 360 | 100 | 770 | 5.5 | 960 | 3260X1700X2260 |

| 80X3200 | 800 | 3200 | 2600 | 250 | 100 | 360 | 100 | 780 | 7.5 | 960 | 3520X1620X2230 |

| 80X4000 | 800 | 4000 | 3200 | 250 | 100 | 360 | 100 | 780 | 7.5 | 960 | 4050X1820X2280 |

| 100X2500 | 1000 | 2500 | 2050 | 320 | 130 | 390 | 100 | 850 | 7.5 | 960 | 2600X1750X2230 |

| 100X3200 | 1000 | 3200 | 2600 | 320 | 130 | 390 | 100 | 850 | 7.5 | 960 | 3500X1750X2230 |

| 100X4000 | 1000 | 4000 | 3200 | 320 | 130 | 390 | 100 | 850 | 7.5 | 960 | 4060X1800X2500 |

| 100X5000 | 1000 | 5000 | 4080 | 320 | 130 | 390 | 100 | 850 | 7.5 | 960 | 5100X1800X2700 |

| 125X2500 | 1250 | 2500 | 2050 | 320 | 130 | 390 | 100 | 850 | 11 | 960 | 2600X1750X2330 |

| 125X3200 | 1250 | 3200 | 2600 | 320 | 130 | 390 | 100 | 850 | 11 | 960 | 3500X1750X2330 |

| 125X4000 | 1250 | 4000 | 3200 | 320 | 130 | 390 | 100 | 850 | 11 | 960 | 4080X1750X2500 |

| 125X5000 | 1250 | 5000 | 4080 | 320 | 130 | 390 | 100 | 850 | 11 | 960 | 5080X1750X2600 |

| 160X3200 | 1600 | 3200 | 2600 | 320 | 200 | 470 | 160 | 840 | 11 | 960 | 3400X2100X2520 |

| 160X4000 | 1600 | 4000 | 3200 | 320 | 200 | 470 | 160 | 840 | 11 | 960 | 4060X2100X2600 |

| 160X5000 | 1600 | 5000 | 4080 | 320 | 200 | 470 | 160 | 840 | 11 | 960 | 5080X2100X2600 |

| 160X6000 | 1600 | 6000 | 4800 | 320 | 200 | 470 | 160 | 840 | 11 | 960 | 6100X2100X2680 |

| 200X3200 | 2000 | 3200 | 2600 | 320 | 200 | 520 | 180 | 850 | 15 | 960 | 3400X2200X2650 |

| 200X4000 | 2000 | 4000 | 3200 | 320 | 200 | 520 | 180 | 850 | 15 | 960 | 4080X2200X2650 |

| 200X5000 | 2000 | 5000 | 4080 | 320 | 200 | 520 | 180 | 850 | 15 | 960 | 5100X2200X2660 |

| 200X6000 | 2000 | 6000 | 4800 | 320 | 200 | 520 | 180 | 850 | 15 | 960 | 6120X2200X2660 |

| 250X3200 | 2500 | 3200 | 2600 | 400 | 250 | 560 | 220 | 865 | 18.5 | 960 | 3400X2300X2800 |

| 250X4000 | 2500 | 4000 | 3200 | 400 | 250 | 560 | 220 | 865 | 18.5 | 960 | 4120X2300X2800 |

| 250X5000 | 2500 | 5000 | 4080 | 400 | 250 | 560 | 220 | 865 | 18.5 | 960 | 5100X2300X2850 |

| 250X6000 | 2500 | 6000 | 4800 | 400 | 250 | 560 | 220 | 865 | 18.5 | 960 | 6120X2300X2900 |

Detailed photos:

CNC system E200 main completed:

* E200 CNC system control 2 axis --- (1) Backgauge distance (2) Ram stroke;

* ball lead screw and servo motor for back guage;

* Main electric components SIEMENS or SCHNEIDER brand;

* Main motor SIEMENS BEIDE brand;

* hydraulic pump is from America brand SUNNY;

* Hydraulic Seal Rings Are From Japan brand NOK;

* Hydraulic valve is America brand OMEGA;

* Electrical Control Box;

* Motorized Back Gauge;

* Pedal Control Switch;

* Standard Punch and Die;

* Back and side safety curtain;

* Foundation Bolts ;

* English Manual;

CNC system E21 main completed:

* with inverter and lead screw for back gauge;

* Main electric components SIEMENS or SCHNEIDER brand ;

* Main motor SIEMENS BEIDE brand;

* hydraulic pump is SUNNY brand (USA);

* Hydraulic Seal Rings Are From Japan, NOK brand;

* Hydraulic valve is from OMEGA brand (USA);

* E21 swing type Control Panel;

* Electrical Control Box;

* Motorized Back Gauge and Pedal Control Switch ;

* Front support arms;

* Standard Punch and Die (fixed on the machine);

* Back and side safety curtain;

* Foundation Bolts;

* English Manual ;