Basic Info.

Model NO.

TPL9004

Power Source

Hydraulic Pressure

Precision

High Precision

Certification

GS, ISO 9001

Condition

New

Transport Package

Plywood Case

Specification

25400*7000*3000mm

Trademark

SUNRISE

Origin

China

HS Code

8462411900

Production Capacity

100 Sets/Year

Product Description

Applicable Industry:

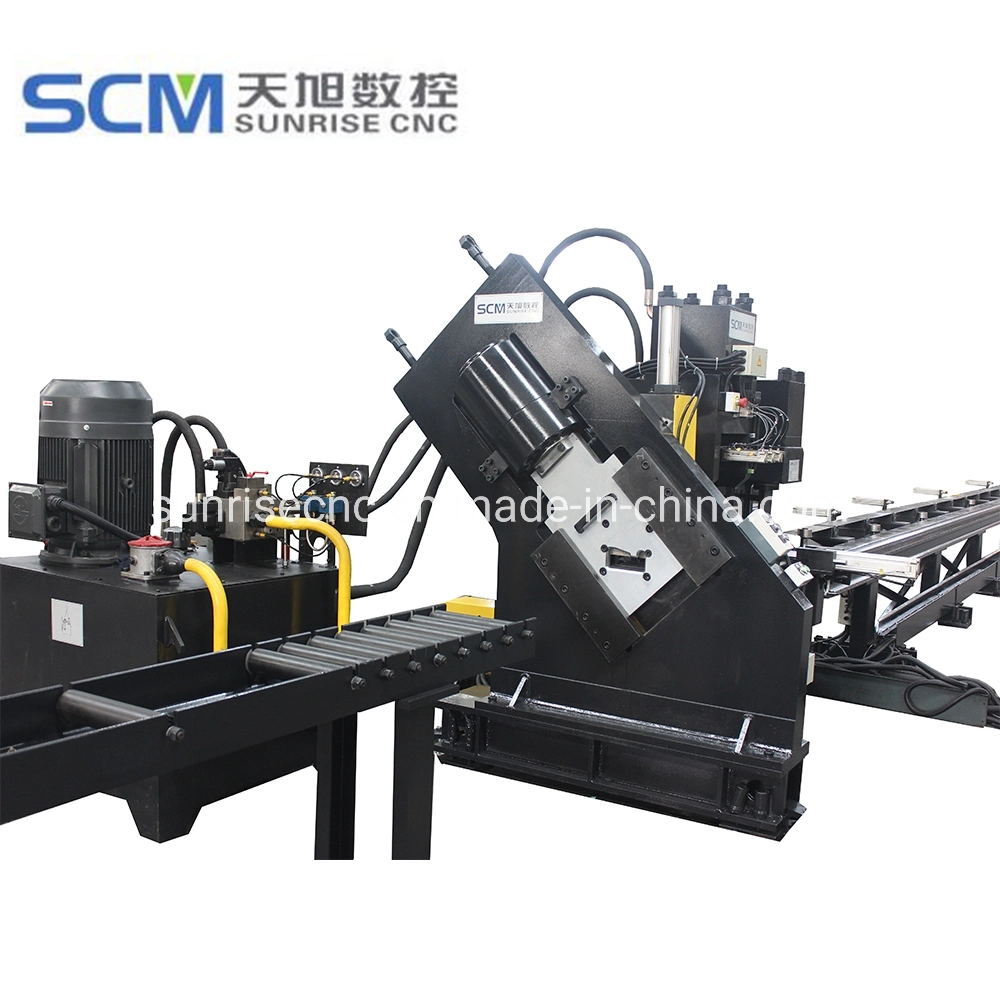

The machine is the automatic special equipment used for flat bar and channel steel marking, punching, and shearing mainly in the field of angle steel tower industry.

Product Feature:

Adopt CNC technology,servo motor infeeding,with high efficiency, stable workpiece precision.Key hydraulic,pneumatic and electric parts all imported.

Easy programming and can directly use the program data made by lofting software.Computer with Chinese/English interface,easy operation, and can display the drawing of workpiece.

All marking,punching and shearing in automatic completeness.

Only need to input size of workpiece,diameter of holes and quantity of workpiece when edit program.

Fast marking speed.

Flat end with single-balde cutting; Circular arc end with double-blade cutting;

With self-diagnosis failures function.

Technical Parameters:

Main Components:

Spare parts list :

The machine is the automatic special equipment used for flat bar and channel steel marking, punching, and shearing mainly in the field of angle steel tower industry.

Product Feature:

Adopt CNC technology,servo motor infeeding,with high efficiency, stable workpiece precision.Key hydraulic,pneumatic and electric parts all imported.

Easy programming and can directly use the program data made by lofting software.Computer with Chinese/English interface,easy operation, and can display the drawing of workpiece.

All marking,punching and shearing in automatic completeness.

Only need to input size of workpiece,diameter of holes and quantity of workpiece when edit program.

Fast marking speed.

Flat end with single-balde cutting; Circular arc end with double-blade cutting;

With self-diagnosis failures function.

Technical Parameters:

| Model | TPL9004 |

| Max.Workpiece length(mm) | 9000 |

| Workpiece width(mm) | 40~120 |

| Channel size(mm) | #6.3,#8,#10,#12.6 (By customer's request) |

| Max.punching diameter(mm) | Φ26 |

| Oval hole(mm) | 22X50 |

| Max.thickness(mm) | 12 |

| Punching force(KN) | 1000 |

| No. of punching die-station | 3 |

| Marking force(KN) | 800 |

| No. of marking die-station | 1 |

| Character size(mm) | 14×10×19 |

| No. of character box | 4 |

| No. of characters | 12 |

| Cutting force(KN) | 1200 |

| Cutting Mode | Single-blade cutting |

| Feeding mode | NC carriage |

| Feeding speed(m/min) | 60 |

| Programming mode | Auto CAD or lofting software |

| Program function | Error display |

Main Components:

| Main Electric Components | |||

| 1 | PLC | Japan Mitsubishi | |

| 2 | Servo Motor | Japan YASKAWA | |

| 3 | Servo Driver | ||

| 4 | Proximity Switch | AUTONICS | |

| 5 | Power | China Aerospace | |

| 6 | Business Computer | China Lenovo | |

| Hydraulic Components | |||

| 1 | Hydraulic solenoid valves(all) | ATOS Italy ATOS | |

| 2 | Vane pump | America Denison | |

Spare parts list :

| No | Name | Qty | Remark | ||

| 1 | punch head | Round hole | Φ14,Φ18 | 1set | |

| Oval hole | Φ14x30,Φ18x30 | ||||

| 2 | Cavity die | Round hole | Φ14.7,Φ18.7 | 1set | |

| Oval hole | Φ14.8*30.8,Φ18.8*30.8 | ||||

| 3 | punch pole for round holes | 3(2) | Including installed in machine | ||

| 4 | punch nut for round holes | 3(2) | Including installed in machine | ||

| 5 | punch pole for heterotypic holes | 2(1) | Including installed in machine | ||

| 6 | punch nut for heterotypic holes | 2(1) | Including installed in machine | ||

| 7 | marking box | 2(1) | Including installed in machine | ||

| 8 | character | 1set | Including installed in machine | ||

| 9 | upper balde | 1set | |||

| 10 | lower balde | 1set | |||

| 11 | Upper claw | 2(1) | Including installed in machine | ||

| 12 | Lower calw | 2(1) | Including installed in machine | ||

| 13 | Proximity switch | 1 | |||

| 14 | Proximity switch | 1 | |||

| 15 | O ring | 1set | |||

| 16 | Inner hexagon spanner | 1set | |||

| 17 | Spanner for punch head | 1 | Manufacturer made | ||

| 18 | 600mm adjustable spanner | 1 | |||

| 19 | Standby paint | 2 | |||

| 20 | Operation Manual | 2sets | |||