Basic Info.

Model NO.

FMJ1530

Laser Technology

Laser Control Fault Cutting

Keywords

Fiber Laser Cutting Machine

Fiber Power

1000W/1500W/2000W/ 3000W

Fiber Generator

Raycus / Ipg

Reducer

Motovario

Laser Cutter Head

Raytools / Lasermech (Optional)

Water Chiller

Hanli

Motor

Yaskawa/ Panasonic /FUJI

Gudie Rail

Hiwin / PMI (Optional)

Cutting Speed

20m/Min--- 60m/Min

Working Table

Saw Tooth Work Table

Transport Package

Plywood

Specification

3000*1500mm

Trademark

FIRMCNC

Origin

China, Shandong, Jinan

HS Code

8456110090

Production Capacity

100 Sets/Month

Product Description

China Top Laser Cutting Machine 1000W Price / CNC Laser Cutter Sheet Metal

Fiber laser cutting machine adopting world famous Germany IPG fiber laser source and Raycus laser source,Raytools cutting head and dynamic focus system, it can cut and punch different kinds of metal material with high precision and high speed. Since laser is transmitted by fiber , it is no need to maintenance or adjusts the laser optical path , it greatly reduces the machines fault rate and prolongs the working life. Large format cutting area meets the demands of various kinds of metal processing .

Features of fiber laser cutting machine

1.Excellent beam quality: Smaller focus diameter , high work efficiency, better processing quality.

2. High cutting speed: 2-3 times faster than YAG and CO2 laser .

3.High Stability: Adopt superior quality fiber laser, stable performance, key parts can reach .

4. High efficiency for photoelectric conversion : Compared with CO2 laser cutting machine, Fiber laser cutting machine has 3 times photoelectric conversion and with energy saving & friendly environment .

5. Low cost: The whole power consumption is only 20-30% of traditional CO2 laser cutting machine.

6.Low maintenance cost: It is with Optical fiber line transmission, no need reflector lens, can save a lot of maintenance cost.

7.Easy Operation : Fiber Line transmission, no adjustment of optical path.

8.Super-flexible optical effect : small volume, compact structure, easy to flexible manufacturing requirements .

Specifications of fiber laser cutting machine

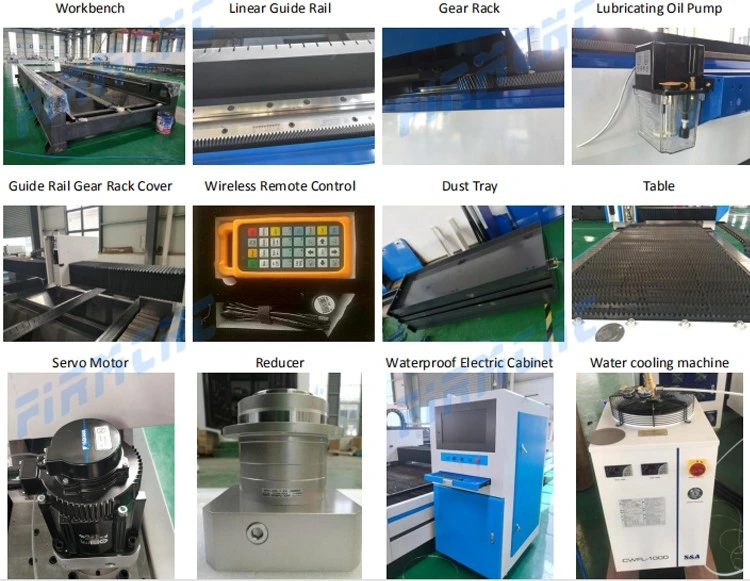

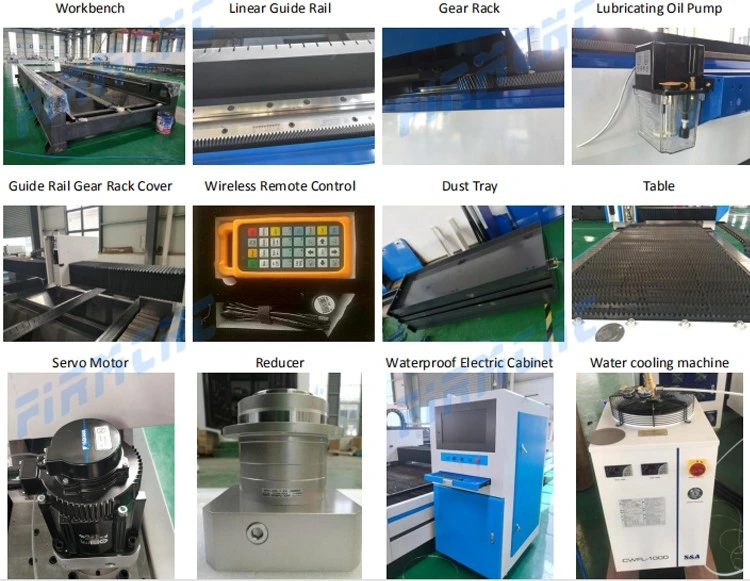

Parts of fiber laser cutting machine

Application Materials of fiber laser cutting machine

Automobile manufacturing, machinery and equipment, electrical equipment, hotel kitchen equipment, elevator equipment, advertising logo, car decoration, sheet metal production, lighting hardware, display equipment, precision parts, hardware products, subway accessories, decoration, textile machinery, food machinery , Construction machinery, ships, tooling, metallurgical equipment, aviation, aerospace and other manufacturing and processing industries.

Samples of fiber laser cutting machine

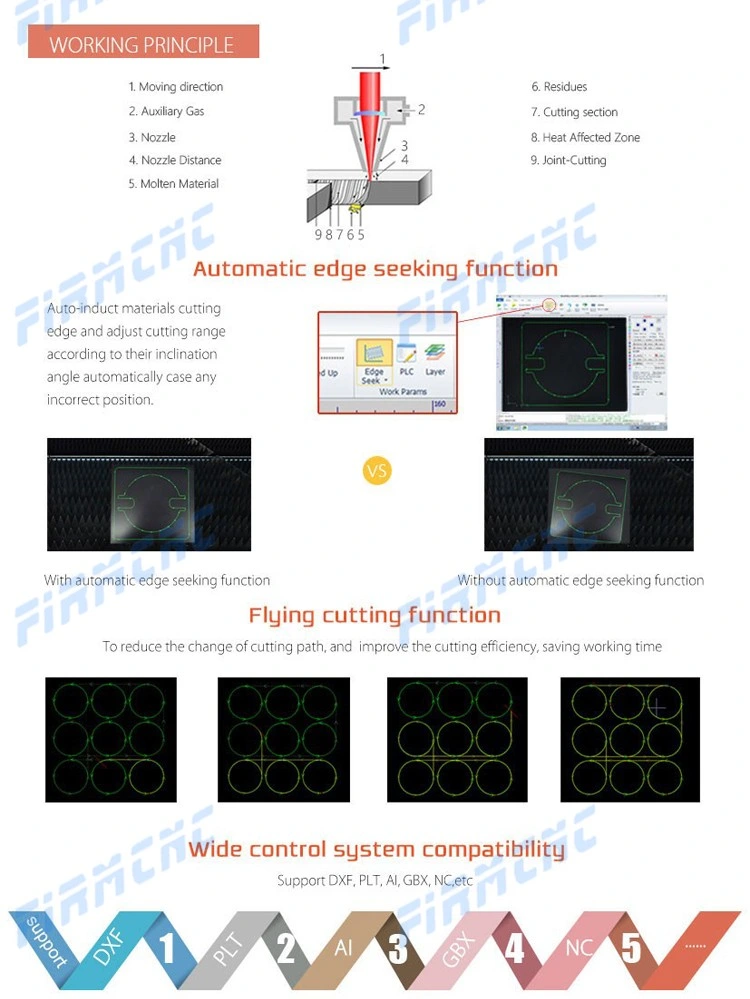

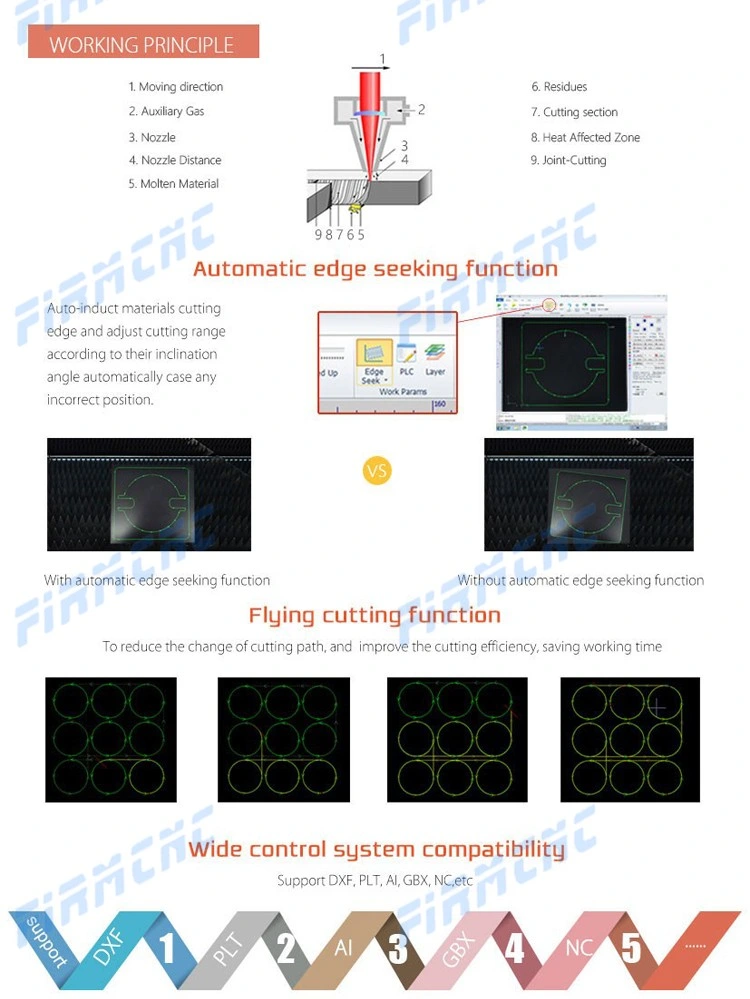

Fiber laser cutting machine working principle

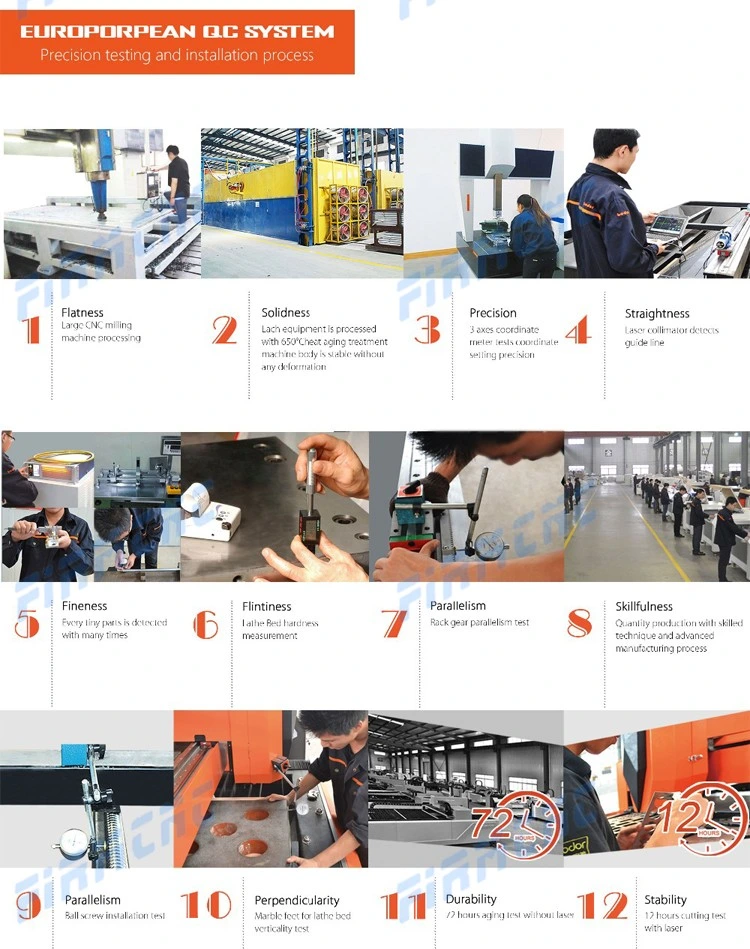

Company Profile

JINAN FIRMCNC EQUIPMENT CO.,LTD the professional cnc router and laser cutting machine manufacturer, which is located in Jinan city ,China

We started to sell cnc machine in China since 2009 ,and then start our business abroad since 2013 , Our machine sells well in global area, like the North America, Europe, Middle East , etc.

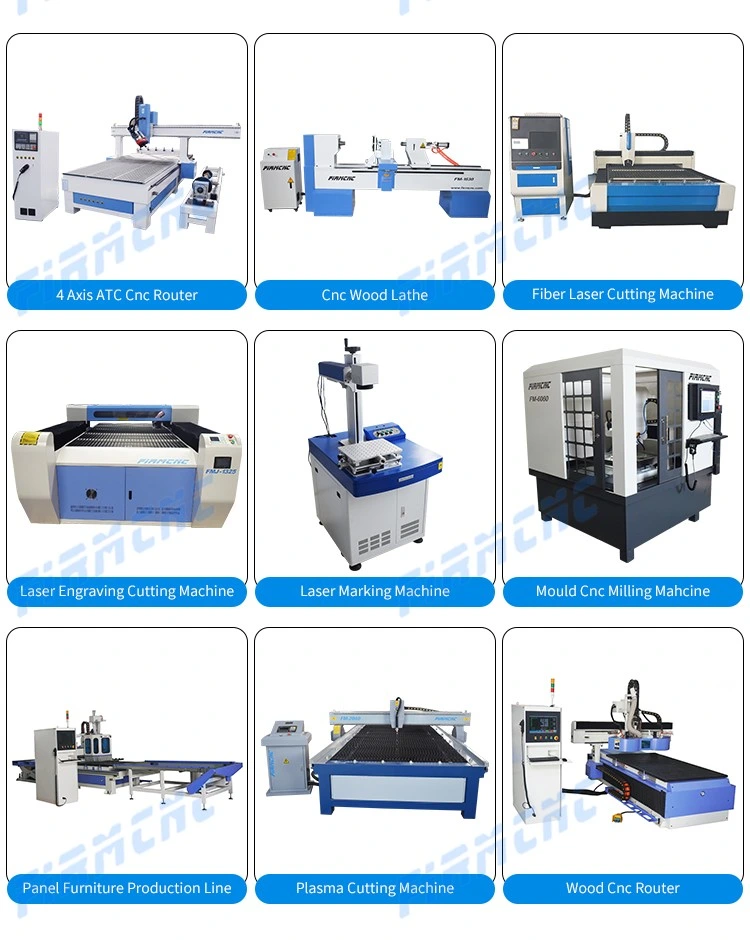

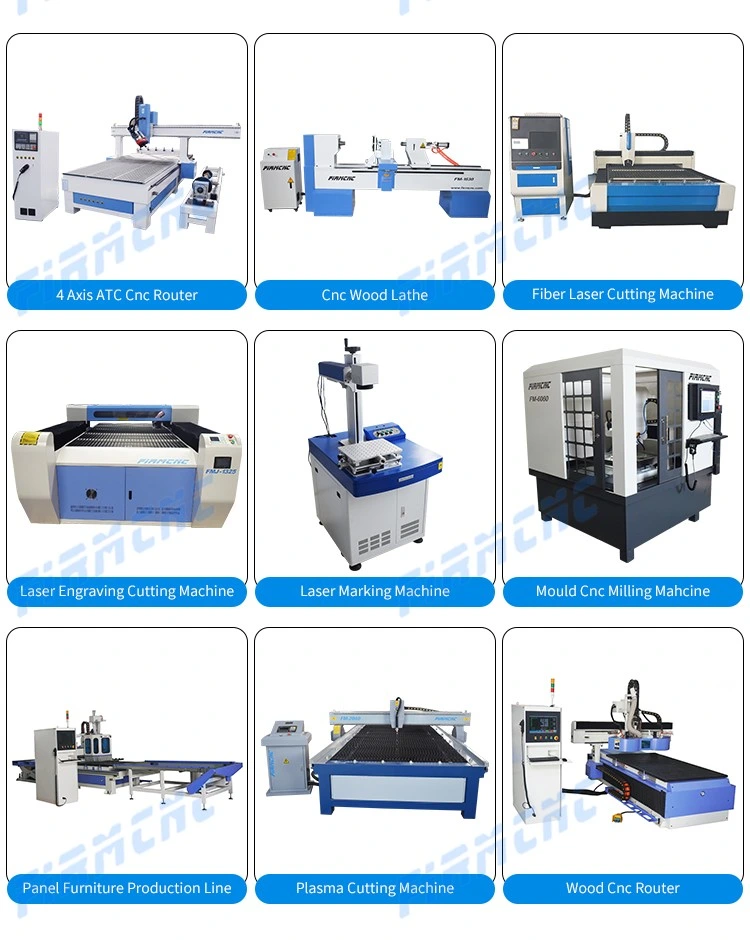

Our machine includes : Woodworking cnc router , Stone engraving machine , Metal mould making machine , 4 axis cnc router , 5 axis cnc router , EPS processing machine , Co2 laser cutting and engraving machine , Fiber laser cutting machine , Laser marking machine , Plasma cutting machine

Our cnc routers are widely used for advertising, woodworking, mould, stone, metal industry.

Customer visit factory

After sale service

1. 24 hour Technical support by phone, e-mail or MSN around the clock.

2. Friendly English version manual and operation video CD disk.

3.7-15 working days after down payment or full payment.

4. Machine will be adjusted before it is delivered; operation disk/CD was included.

5. Our technician can give you remote guide online (Skype or MSN) if you have any question.

6. Engineers available to service machinery overseas, seller and buyer discuss the charges

Delivery & Payment

Packaging and shipping

1) Foam and wrapping film on the surface of the machine inside. Rain-proof, Dust proof.

2)Standard export plywood case. Upwards, moistureproof shipping marks. Safety guaranteed.

3) fumigation-free

4)With shipping mark if you like.

5)Outside: Marked packing size, model, weight and other information.

More Products

FAQ

Q1.Can you recommend a fiber laser cutting machine to me ?

Yes, In order to give you a suitable fiber laser cutting machine,pls tell me your working area ? processing materials ?

Then perfect suitable machine will be recommend.

Q2.Do you have operation manual and working video?

Yes, after we confirm order, operation manual will be send to you.

Q3.Does your company can processing my samples?

Yes, we can.

Q4.If I bought machine, but don't know how to operation, what I can do?

Our engineer will teach you how to operation the machine through manual, video call or email, I still aso will help you .

Q5.How am I going to work on service parts on the machine? Example what if parts need to be replaced?

During the period of warranty, we will free send broken parts to you, after warranty, we can offer agent price for parts.

usually for all parts can perfect working one year without any broken .

Q6.Does your engineer do aftersale service at abroad? how much cost?

Yes, our technician can do training and after sale service at yoru factory, you only need to pay the round air tickets cost and accommodation for technician.

Fiber laser cutting machine adopting world famous Germany IPG fiber laser source and Raycus laser source,Raytools cutting head and dynamic focus system, it can cut and punch different kinds of metal material with high precision and high speed. Since laser is transmitted by fiber , it is no need to maintenance or adjusts the laser optical path , it greatly reduces the machines fault rate and prolongs the working life. Large format cutting area meets the demands of various kinds of metal processing .

Features of fiber laser cutting machine

1.Excellent beam quality: Smaller focus diameter , high work efficiency, better processing quality.

2. High cutting speed: 2-3 times faster than YAG and CO2 laser .

3.High Stability: Adopt superior quality fiber laser, stable performance, key parts can reach .

4. High efficiency for photoelectric conversion : Compared with CO2 laser cutting machine, Fiber laser cutting machine has 3 times photoelectric conversion and with energy saving & friendly environment .

5. Low cost: The whole power consumption is only 20-30% of traditional CO2 laser cutting machine.

6.Low maintenance cost: It is with Optical fiber line transmission, no need reflector lens, can save a lot of maintenance cost.

7.Easy Operation : Fiber Line transmission, no adjustment of optical path.

8.Super-flexible optical effect : small volume, compact structure, easy to flexible manufacturing requirements .

Specifications of fiber laser cutting machine

| Fiber Laser Cutting Machine Technical Parameters | |

| Laser Type | Fiber laser |

| Laser Brand | IPG / Raycus |

| Laser Power | 1000W / 2000W / 3000W |

| Working area | 1500mmX3000mm / 2000mmX4000mm / |

| 2000mmmX6000mm | |

| Working Table | Fixed Working Table / Pallet Changer |

| Control System | PMAC full-closed loop servo control |

| Driving Mode | Double ball screw driving / Double gear rack driving |

| Idle/Processing Speed | 120m/min / 60m/min |

| Positioning Accuracy | 0.05mm |

| Protection System | Enclosure protection |

| Laser Head | Precitec / Raytools |

| Power Supply | AC220V ± 5% 50 / 60Hz / AC380V ± 5% 50 / 60Hz |

| Total Power | 6KW~20KW |

| Floor Space | 5.6mX3.2m (fixed table) / 6mX4.6m (shuttle working table) |

| / 8.5mX4.2m (pallet changer) | |

| Standard Collocation | Metal nesting software, dual-pressure gas route of 3 kind gas sources, |

| dynamic focus, remote controller, etc. | |

| Auxiliary System | |

| Cooling System | Dual temperature dual control water chiller |

| with purification system | |

| Lubrication System | Automatic lubrication |

| Laser cooling system | Horizontal air conditioning |

| Auxiliary gas system | dual-pressure gas route of 3 kind gas sources |

| Laser cutting head | Dynamic focus |

| Circuit and protection system | Independent work station |

| Software System | |

| Software | Shanghai Cypcut |

| Supported Format | PLT, DXF, BMP, AI, DST, DWG, etc. |

Application Materials of fiber laser cutting machine

Automobile manufacturing, machinery and equipment, electrical equipment, hotel kitchen equipment, elevator equipment, advertising logo, car decoration, sheet metal production, lighting hardware, display equipment, precision parts, hardware products, subway accessories, decoration, textile machinery, food machinery , Construction machinery, ships, tooling, metallurgical equipment, aviation, aerospace and other manufacturing and processing industries.

Samples of fiber laser cutting machine

Cutting ability & Consume

| Material | Thickness(mm) | Speed(mm/s) | Gas Pressure(MPa) | Gas | Cutting Height |

| Stainless Steel | 0.5 | >200 | 1 | N2 | 0.6 |

| 1 | 90~120 | >1.1 | N2 | 0.6 | |

| 2 | 16~20 | >1.5 | N2 | 0.6 | |

| Carbon Steel | 1 | 120~150 | 1 | O2 | 1 |

| 2 | 35~45 | 0.6~0.8 | O2 | 1 | |

| 3 | 15~18 | 0.3~0.5 | O2 | 1 |

Company Profile

JINAN FIRMCNC EQUIPMENT CO.,LTD the professional cnc router and laser cutting machine manufacturer, which is located in Jinan city ,China

We started to sell cnc machine in China since 2009 ,and then start our business abroad since 2013 , Our machine sells well in global area, like the North America, Europe, Middle East , etc.

Our machine includes : Woodworking cnc router , Stone engraving machine , Metal mould making machine , 4 axis cnc router , 5 axis cnc router , EPS processing machine , Co2 laser cutting and engraving machine , Fiber laser cutting machine , Laser marking machine , Plasma cutting machine

Our cnc routers are widely used for advertising, woodworking, mould, stone, metal industry.

Customer visit factory

After sale service

1. 24 hour Technical support by phone, e-mail or MSN around the clock.

2. Friendly English version manual and operation video CD disk.

3.7-15 working days after down payment or full payment.

4. Machine will be adjusted before it is delivered; operation disk/CD was included.

5. Our technician can give you remote guide online (Skype or MSN) if you have any question.

6. Engineers available to service machinery overseas, seller and buyer discuss the charges

Delivery & Payment

Packaging and shipping

1) Foam and wrapping film on the surface of the machine inside. Rain-proof, Dust proof.

2)Standard export plywood case. Upwards, moistureproof shipping marks. Safety guaranteed.

3) fumigation-free

4)With shipping mark if you like.

5)Outside: Marked packing size, model, weight and other information.

More Products

FAQ

Q1.Can you recommend a fiber laser cutting machine to me ?

Yes, In order to give you a suitable fiber laser cutting machine,pls tell me your working area ? processing materials ?

Then perfect suitable machine will be recommend.

Q2.Do you have operation manual and working video?

Yes, after we confirm order, operation manual will be send to you.

Q3.Does your company can processing my samples?

Yes, we can.

Q4.If I bought machine, but don't know how to operation, what I can do?

Our engineer will teach you how to operation the machine through manual, video call or email, I still aso will help you .

Q5.How am I going to work on service parts on the machine? Example what if parts need to be replaced?

During the period of warranty, we will free send broken parts to you, after warranty, we can offer agent price for parts.

usually for all parts can perfect working one year without any broken .

Q6.Does your engineer do aftersale service at abroad? how much cost?

Yes, our technician can do training and after sale service at yoru factory, you only need to pay the round air tickets cost and accommodation for technician.