Basic Info.

Model NO.

BCNC-450

Automation

Automatic

Cutting Ability

High Speed

Control

CNC

Certification

ISO, CE

Overall Weight

4000 Kg

Work Bench Specifications

3300X2000

Control System

Esa CNC

Transport Package

Plastic Packing

Specification

5700x3260x2765 mm

Trademark

BCMC

Origin

Putian, Fujian, China

HS Code

8464109000

Production Capacity

50 Pieces/Month

Product Description

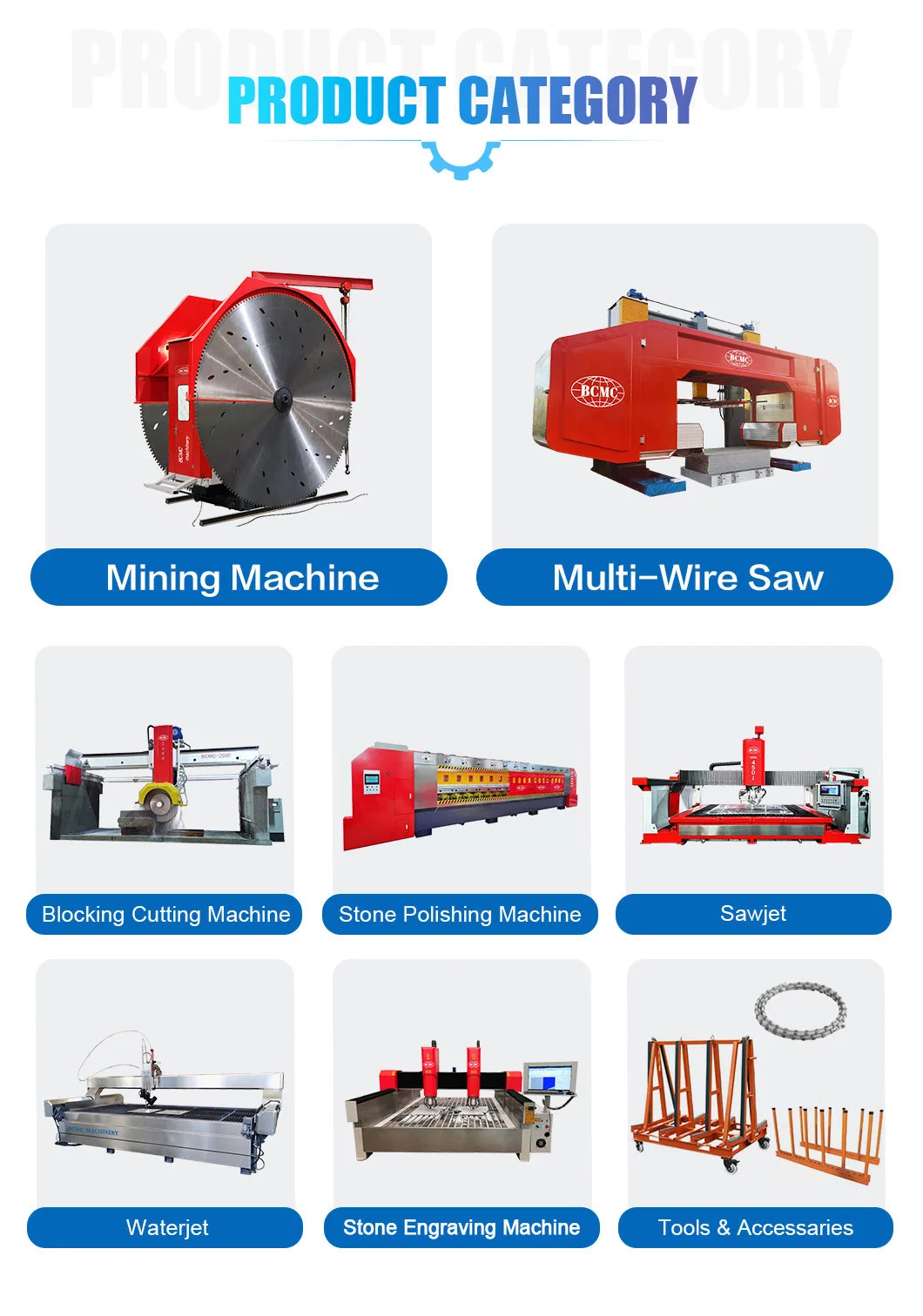

BCMC Machinery BCNC-450. This is a kind of new generation light weight stone cutting machine. Equipped with the world famous italian CNC control system and already installed CAD, CAM software. Qualified in stone processing and shaping. The machine is controlled by easy operation and interactive touch screen computer. Make your stone cutting and shaping process easy and efficient.

Main Features:

Paremeters:

Detailed Information For Spare Parts:

Final Products

Application:

* 3D decorative wall panels

* Countertops

* Cut curves and contours

* Doorsteps, staircases and thresholds

* Fireplaces

* Flooring

* Funerary art/tombstone

* Street furniture

* Ventilated facades

Main Features:

- 5 axes interpolated control.

- Big touch screen CNC control system. Easy to control.

- Photograohing camera equipped. Helps for slab positioning and typesetting. Save time and reduce the waste of processing.

- Vacuum lifter equipped. Easy moving slabs for cutting and processing.

- Milling cutter for doing the hole drilling and sink cutting work.

- Multifunctional processing function which can doing the complex work of cutting, milling, drilling and carving and even the curved surface processing.

- Cutter head can tilt in 90 degrees vertical and rotate in 360 degrees horizontal. Handling chamfer cutting at any angles automatically.

- Work bench can tilt in 85 degrees and all around rotate for easy slab loading and changing.

- Easy for loading, unloading and installation due to the monobloc structure.

- USB and WIFI connection. Easy to connect and upload your CAD/CAM files to the machine.

Paremeters:

| Diameter of saw blade | mm | ø350-ø450 |

| Dimension of working platform | mm | 3300x2000 |

| Max. cutting length | mm | 3300 |

| Max. cutting thickness | mm | 100 |

| Max. lifting stroke | mm | 250 |

| Max. lifting weight by sunction cups | kg | 200 |

| Power of main motor | kw | 15 |

| Power of cutter frame reciproctating motor | kw | 2 |

| Power of crossbeam shifting motor | kw | 1.1 |

| Power of hydraulic station motor | kw | 2.2 |

| Power of lifting motor | kw | 0.85 |

| Gross power | kw | 16 |

| Water consumption | m3/h | 2 |

| Gross weight | kg | 4000 |

| Dimensions (L x W x H) | mm | 5700x3260x2765 |

Detailed Information For Spare Parts:

Control system:

Italian ESA CNC control system with touch screen for computer setting and controlling easily and visiable. Make your complicated work easily and high effficience. No need to switch from PC to machine frequently.

Italian ESA CNC control system with touch screen for computer setting and controlling easily and visiable. Make your complicated work easily and high effficience. No need to switch from PC to machine frequently.

Digital Servomotor:

Italian ESA digital servomotor. Using a kind of permanent magnet brushless servomotor with intergrated drives, designed to achieve total digital integration with ESA CNC control system, creates a reliable controlling power for X, Y, Z, A and C axes.

Italian ESA digital servomotor. Using a kind of permanent magnet brushless servomotor with intergrated drives, designed to achieve total digital integration with ESA CNC control system, creates a reliable controlling power for X, Y, Z, A and C axes.

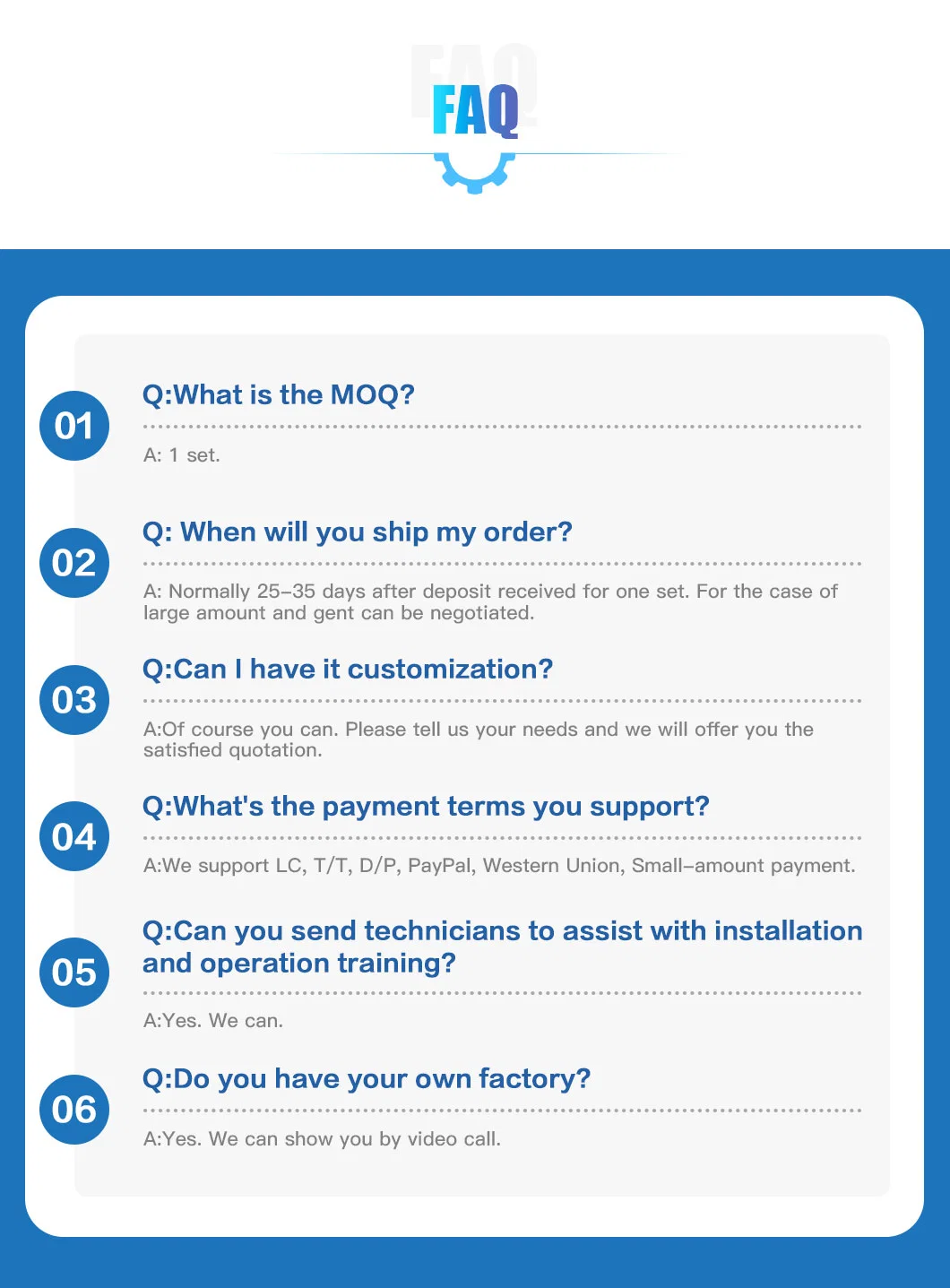

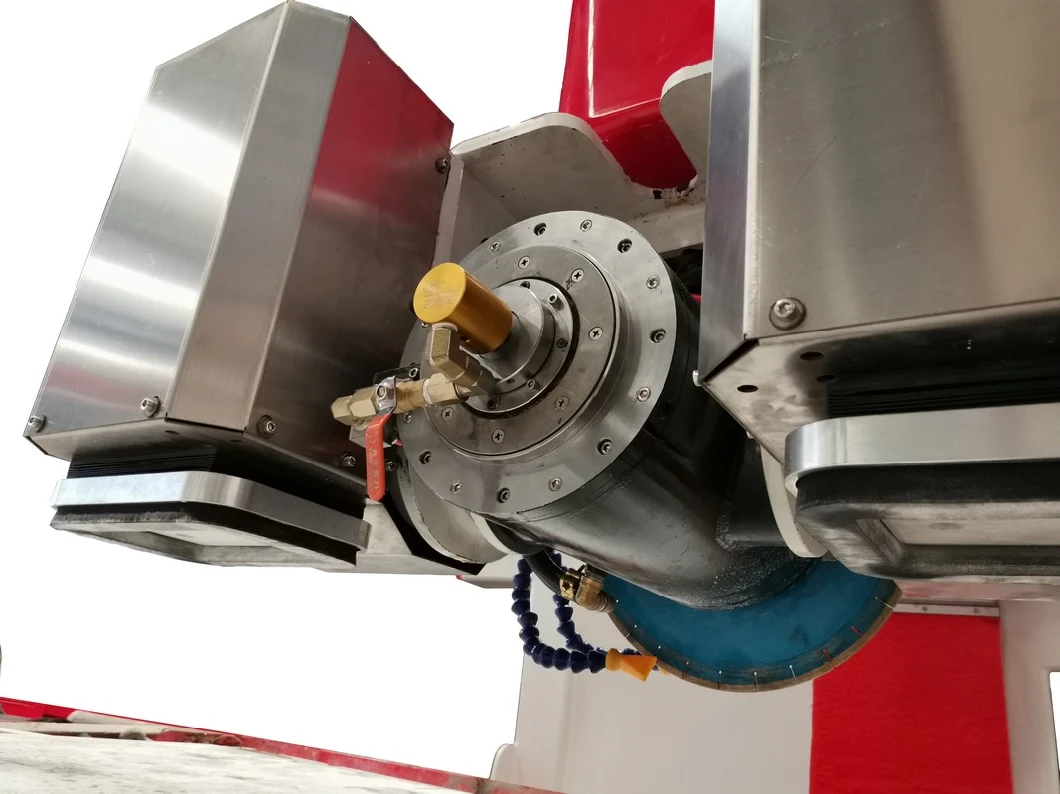

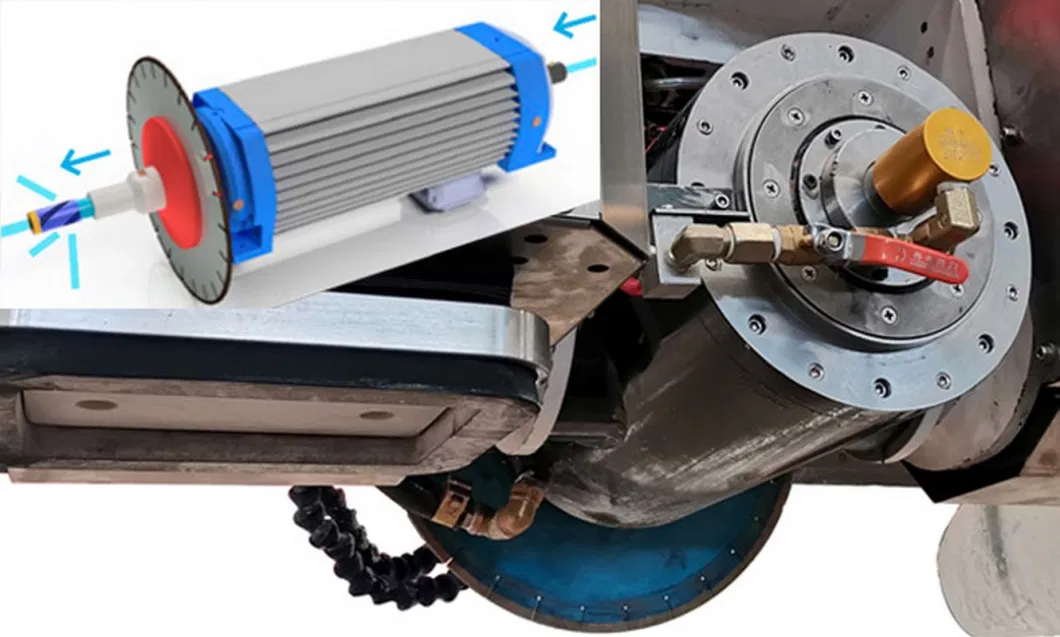

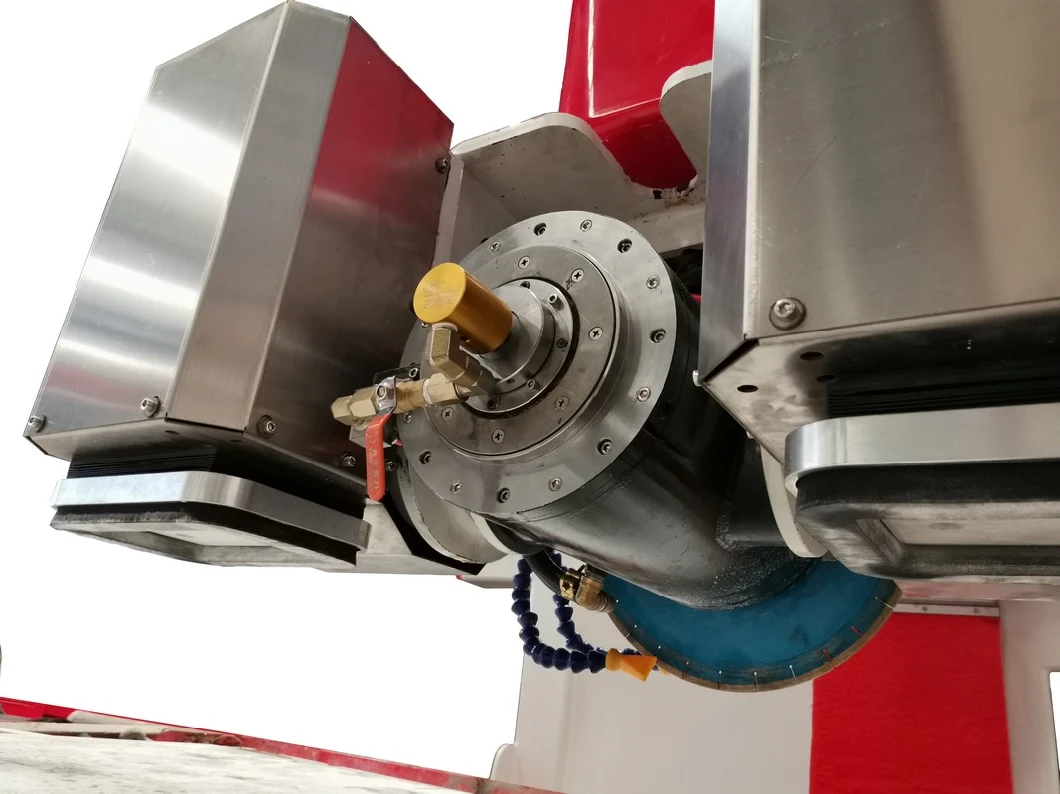

Electro-spindle

High quality Electro-spindle controlled by an inverter allowing the adjustment of revolutions from 0 to 6000 rpm, so granting the use of blade and diamond tools such as a core drill or milling cutter. The tool change is of manual type.

High quality Electro-spindle controlled by an inverter allowing the adjustment of revolutions from 0 to 6000 rpm, so granting the use of blade and diamond tools such as a core drill or milling cutter. The tool change is of manual type.

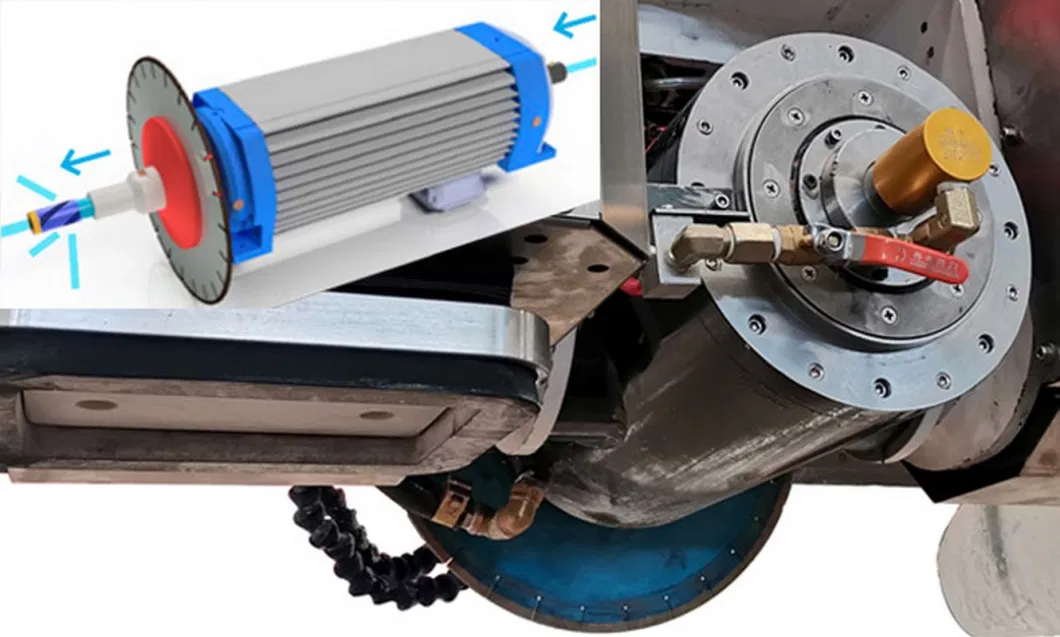

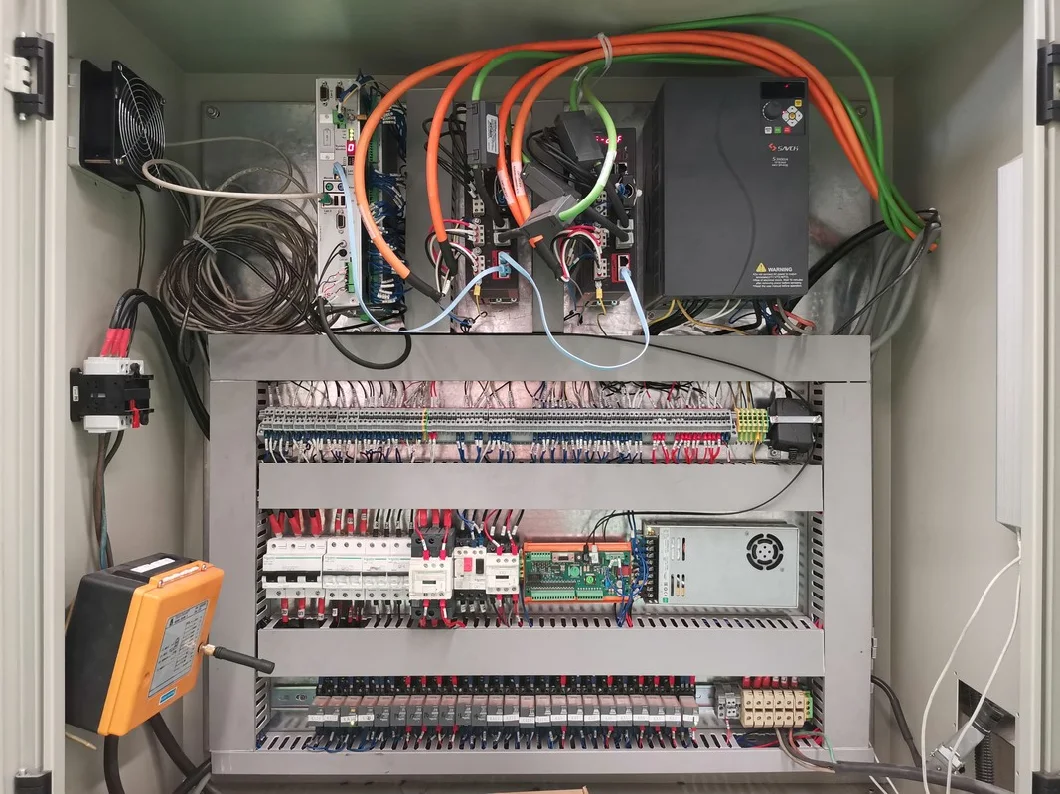

Electric Cabinet

Using the branded electric component as ESA, Schnider, Sanch to ensure the stable performance.

Using the branded electric component as ESA, Schnider, Sanch to ensure the stable performance.

Linear Guide

Hiwin linear guide used on crossbeam and carling for high precision of cutting and long lifespan.

Hiwin linear guide used on crossbeam and carling for high precision of cutting and long lifespan.

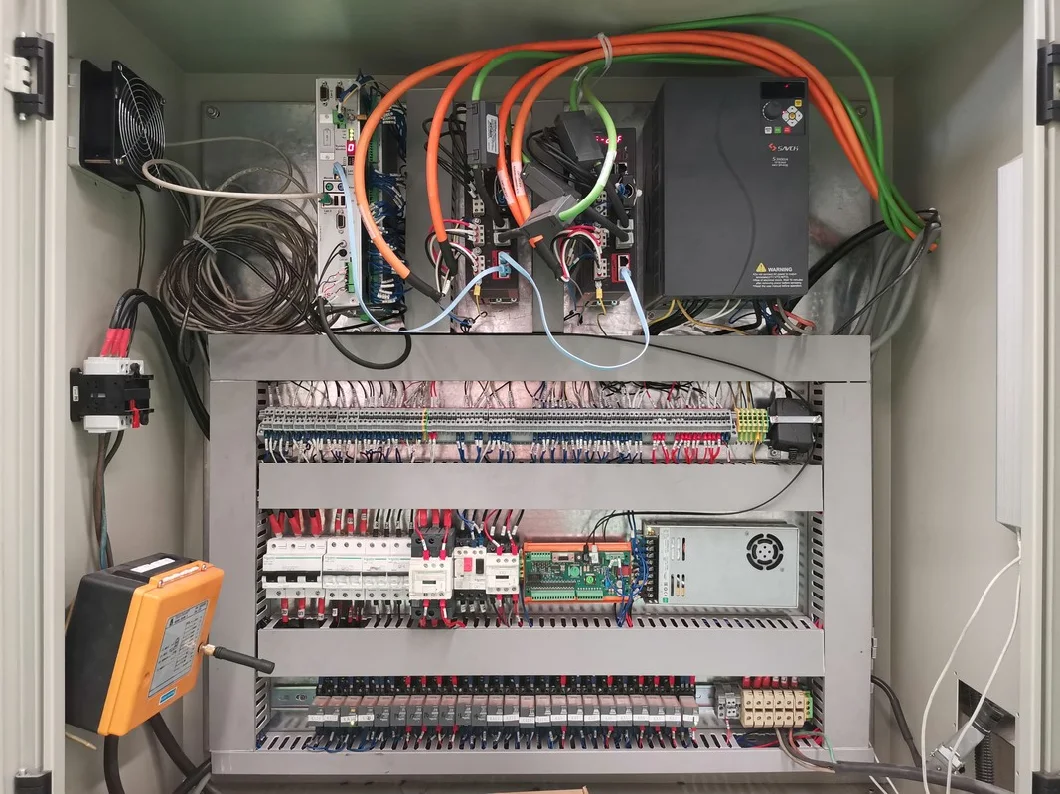

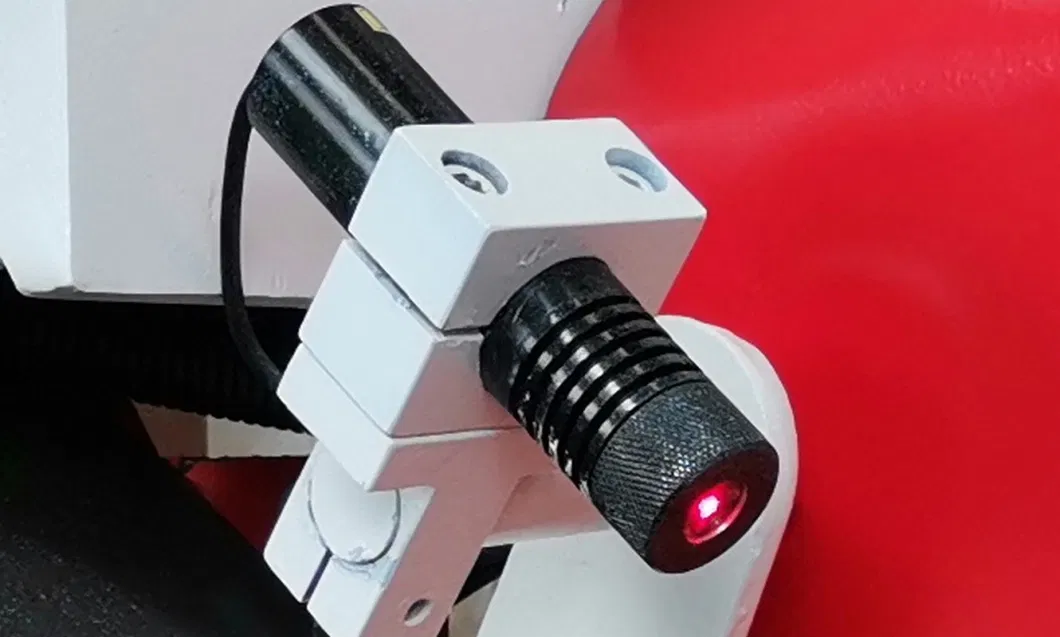

Laser Reticule Apparatus

Laser checking and calibration instrument to aid in lining up the cut at the beginning of processing.

Laser checking and calibration instrument to aid in lining up the cut at the beginning of processing.

Vacuum Lifter(Optional)

Laser checking and calibration instrument to aid in lining up the cut at the beginning of processing.

Laser checking and calibration instrument to aid in lining up the cut at the beginning of processing.

| Photo Slab System(Optional) Detecting slab with camera positioned above the machine and image acquisition software to catch the slab dimensions to be exploited in the best way possible and carry on the cutting avoiding any defects or any veins in the material. |

| Blade prosetting Unit(Optional) Automatically measuring blade diameter and diamond tool |  |

| Slab thickness Detector(Optional) Automatically measuring blade diameter and diamond tool |

| Vein Matching Function(Optional) Easily match up each vein and seam of your project |  |

Final Products

Application:

* 3D decorative wall panels

* Countertops

* Cut curves and contours

* Doorsteps, staircases and thresholds

* Fireplaces

* Flooring

* Funerary art/tombstone

* Street furniture

* Ventilated facades