Basic Info.

Product Description

Fiber Laser Cutter Cutting Machines laser equipment

Fiber Laser Cutting Machine Product Advantage:

Glorious Laser provides different series of products in order to satisfy customers' comprehensive needs. In Glorious Laser, there are totally 9 types of products with different functions from 1000 watts to 15000 watts to satisfy customers' various needs in metal cutting under different types, shapes, sizes and maximum thicknesses.

Functions:

1) Auxiliary feeding mechansism

2) Intelligent travel protection

3) Automatic lubrication

4) Global real-time feedback

5) A new generation of safety following module

6) Intelligent alarm system

7) Auxiliary gas low pressure alarm fuction

Main sales territory: regions Europe, the United States, Russia, Ukraine, South America, Africa, southeast Asia and Australia.

Parameter&configration List:

| Parameter & configration List | |||||||

| Item | Subitem | GP12030 | GP8025 | GP6025 | GP6020 | GP4020 | GP3015 |

| Basic parameter | Working area | 12500mm*3200mm | 8100mm*2500mm | 6100mm*2500mm | 6100mm*2000mm | 4000mm*2000mm | 3000mm*1500mm |

| Table load bearing | 12500kg | 6000kg | 2950kg ≥15KW:4200kg | 2400kg ≥15KW:3300kg | 1600kg ≥15KW:2200kg | 900kg | |

| Machine overall dimensions | 31200*6150*2400mm | 19700*4200*2400mm | 15300*4500*2400mm | 15000*4000*2300mm | 12000*3700*2300mm | 9950*3050*2300mm | |

| Machine weight | 65000kg | 22500kg | 19500kg | 17500kg | 11000kg | 8300kg | |

| Z axis travel | 400mm | 120mm | 315mm | 315mm | 315mm | 315mm | |

| Fastest exchange time of platforms | 80s | 60s | 30s | 30s | 10s | 10s | |

| Operation parameter | Max. linkage speed | 80m/min | 140m/min | 140m/min | 140m/min | 140m/min | 140m/min |

| Max. acceleration | 0.8G | 1.5G | 1.5G | 1.5G | 1.5G | 1.5G | |

| Positioning accuracy | 0.05mm/m | 0.05mm | 0.05mm | 0.05mm | 0.05mm | 0.03mm | |

| Repositioning accuracy | 0.03mm/m | 0.03mm | 0.03mm | 0.03mm | 0.03mm | 0.02mm | |

| processing precision (1mm Original box carbon steel plate) | Φ30mm roundness | ≤0.1mm | ≤0.1mm | ≤0.1mm | ≤0.1mm | ≤0.1mm | ≤0.1mm |

| 30mm adjacent side dimension difference | ≤0.04mm | ≤0.04mm | ≤0.04mm | ≤0.04mm | ≤0.04mm | ≤0.04mm | |

| 190mm adjacent side dimension difference | ≤0.06mm | ≤0.06mm | ≤0.06mm | ≤0.06mm | ≤0.06mm | ≤0.06mm | |

| 190mm diagonal size difference | ≤0.07mm | ≤0.07mm | ≤0.07mm | ≤0.07mm | ≤0.07mm | ≤0.07mm | |

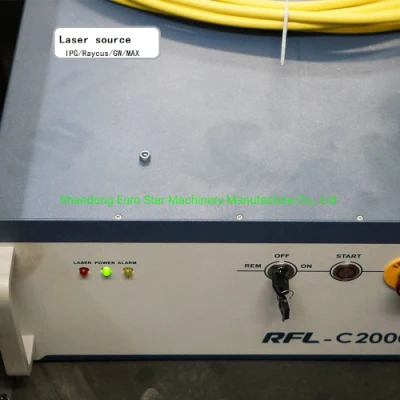

| Optical system | Laser source | MAX/IPG Raycus/GW | MAX/IPG Raycus/GW | MAX/IPG Raycus/GW | MAX/IPG Raycus/GW | MAX/IPG Raycus/GW | MAX/IPG Raycus/GW |

| laser head | 6KW:WSX/Raytools/Hsns 6KW above:Gemany Precitec | 6KW:WSX/Raytools/Hsns 6KW above:Gemany Precitec | 6KW:WSX/Raytools/Hsns 6KW above:Gemany Precitec | 6KW:WSX/Raytools/Hsns 6KW above:Gemany Precitec | 6KW:WSX/Raytools/Hsns 6KW above:Gemany Precitec | 6KW:WSX/Raytools/Hsns 6KW above:Gemany Precitec | |

| Precitec Special Laser Head Equipped with External Water Cooling | standard configuration | standard configuration | standard configuration | standard configuration | standard configuration | standard configuration | |

| Automatic focusing function of laser head | standard configuration | standard configuration | standard configuration | standard configuration | standard configuration | standard configuration | |

| Multi-stage perforation Technology | standard configuration | standard configuration | standard configuration | standard configuration | standard configuration | standard configuration | |

| smooth cutting technology | standard configuration | standard configuration | standard configuration | standard configuration | standard configuration | standard configuration | |

| Anti-slag protection function of double cyclones | standard configuration | standard configuration | standard configuration | standard configuration | standard configuration | standard configuration | |

| mechanical system | Machine bed | Segmented Cast iron bed | Cast iron bed | Cast iron bed | Cast iron bed | Cast iron bed | Cast iron bed |

| X-axis,Y-axis,Z-axisServo motor and driver | Japan Yaskawa | Japan Yaskawa | Japan Yaskawa | Japan Yaskawa | Japan Yaskawa | Japan Yaskawa | |

| Slideway | Made in Taiwan | Made in Taiwan | Made in Taiwan | Made in Taiwan | Made in Taiwan | Made in Taiwan | |

| Rack | Made in Taiwan | Made in Taiwan | Made in Taiwan | Made in Taiwan | Made in Taiwan | Made in Taiwan | |

| Closed protection enclosure | Semi-closed | standard configuration | standard configuration | standard configuration | standard configuration | standard configuration | |

| Automatic lubrication function | standard configuration | standard configuration | standard configuration | standard configuration | standard configuration | standard configuration | |

| Countertop locking function | standard configuration | standard configuration | standard configuration | standard configuration | standard configuration | standard configuration | |

| Intelligent control system | Control system | Cypcut | Cypcut | Cypcut | Cypcut | Cypcut | Cypcut |

| Display size | 21.5 inches | 32 inches | 32 inches | 32 inches | 32 inches | 32 inches | |

| WIFI wireless control | standard configuration | standard configuration | standard configuration | standard configuration | standard configuration | standard configuration | |

| Nozzle automatic calibration function | No configuration required | standard configuration | standard configuration | standard configuration | standard configuration | standard configuration | |

| Nozzle automatic cleaning function | No configuration required | optional configuration | optional configuration | optional configuration | optional configuration | optional configuration | |

| Process monitoring | standard configuration | standard configuration | standard configuration | standard configuration | standard configuration | standard configuration | |

| Active obstacle avoidance function | standard configuration | standard configuration | standard configuration | standard configuration | standard configuration | standard configuration | |

| Laser cutting technology database | standard configuration | standard configuration | standard configuration | standard configuration | standard configuration | standard configuration | |

| Auxiliary gas low pressure alarm function | standard configuration | standard configuration | standard configuration | standard configuration | standard configuration | standard configuration | |

| Cutting gas automatic pressure regulation function | O2,N2,air | 6KW below:O2 6KW and above:O2,N2,air | 6KW below:O2 6KW and above:O2,N2,air | 6KW below:O2 6KW and above:O2,N2,air | 6KW below:O2 6KW and above:O2,N2,air | 6KW below:O2 6KW and above:O2,N2,air | |

| Breaker | France Schneide | France Schneide | France Schneide | France Schneide | France Schneide | France Schneide | |

| Relay | France Schneide | France Schneide | France Schneide | France Schneide | France Schneide | France Schneide | |

| Electrical proportional valve | Germany AVENTICS | Germany AVENTICS | Germany AVENTICS | Germany AVENTICS | Germany AVENTICS | Germany AVENTICS | |

| O2 Cutting gas control valve | Germany AVENTICS | Germany AVENTICS | Germany AVENTICS | Germany AVENTICS | Germany AVENTICS | Germany AVENTICS | |

| N2 Cutting gas control valve | Germany AVENTICS | Germany AVENTICS | Germany AVENTICS | Germany AVENTICS | Germany AVENTICS | Germany AVENTICS | |

| System identification file format | G file,DXF,PLT,AI | G file,DXF,PLT,AI | G file,DXF,PLT,AI | G file,DXF,PLT,AI | G file,DXF,PLT,AI | G file,DXF,PLT,AI | |

| Safety protection system | Large enclosure open door protection | standard configuration | standard configuration | standard configuration | standard configuration | standard configuration | standard configuration |

| Laser abnormal alarm | standard configuration | standard configuration | standard configuration | standard configuration | standard configuration | standard configuration | |

| Cutting abnormal alarm | standard configuration | standard configuration | standard configuration | standard configuration | standard configuration | standard configuration | |

| Gas low pressure alarm | standard configuration | standard configuration | standard configuration | standard configuration | standard configuration | standard configuration | |

| Water cooler abnormal alarm | standard configuration | standard configuration | standard configuration | standard configuration | standard configuration | standard configuration | |

| Laser protective glasses | standard configuration | standard configuration | standard configuration | standard configuration | standard configuration | standard configuration | |

| Peripheral system | Water cooler | standard configuration | standard configuration | standard configuration | standard configuration | standard configuration | standard configuration |

| Dust removal | Centrifugal fan | Centrifugal fan | Centrifugal fan | Centrifugal fan | Centrifugal fan | Centrifugal fan | |

| Other parameters configuration | Integral aluminum cantilever for high pressure steel mould casting | No configuration required | No configuration required | No configuration required | No configuration required | No configuration required | No configuration required |

| Total power/current with30KW source | 175KW/329A | No configuration required | No configuration required | No configuration required | No configuration required | No configuration required | |

| Total power/current with 20KW source | 128.8KW/245A | 118.9kW/282.3A | 118.9kW/282.3A | 112.9kW/268.1A | 107.9kW/256.2A | No configuration required | |

| Total power/current with 15KW source | 107.8KW/203A | 92.4kW/219.4A | 92.4kW/219.4A | 86.4kW/205.2A | 81.4kW/193.3A | No configuration required | |

| Total power/current with 12KW source | 92.2KW/174A | 76kW/181A | 72.1kW/171A | 66.1kW/157A | 61kW/145A | No configuration required | |

| Total power/current with 8KW IPG source | 76kW/181A | 66kW/157A | 62.1kW/147A | 56.1kW/133A | 50kW/119A | No configuration required | |

| Total power/current with 6KW source | 68.7KW/129.2A | 56kW/132A | 52.1kW/123.7A | 46.1kW/109.5A | 40kW/95.2A | 37kW/89A | |

| Total power/current with 3KW source | No configuration required | 49.7kW/118A | 39.7kW/94.3A | 33.7kW/80.1A | 27.7kW/65.8A | 25kW/60A | |

| Total power/current with 2KW source | No configuration required | 46kW/109.3A | 36kW/85.5A | 30kW/71.3A | 24kW/57A | 21kW/51A | |

| Total power/current with 1.5KW source | No configuration required | 44kW/104.5A | 34kW/80.8A | 28kW/66.5A | 22kW/52.3A | 19kW/46A | |

| Total power/current/current with 4KW source | No configuration required | 42.8kW/101.7A | 32.8kW/77.9A | 26.8kW/63.7A | 20.8kW/49.4A | 18kW/43A | |

| Multifunctional ergonomic handle | No configuration required | standard configuration | standard configuration | standard configuration | standard configuration | standard configuration | |

| Option | laser fume filter(Made in China) | 1set | 1set | 1set | 1set | 1set | 1set |

| laser fume filter(America Donaldson) | DFOE6-1 set | Model: DFOE6-1 set | Model: DFOE6-1 set | Model: DFOE6-1 set | Model: DFOE6-1 set | DFOE4-1 set | |

| security light curtains Generally, 1 set, large equipment or have special requirements, and other non-standard.(CE and ETL certification standard) | standard configuration | optional configuration | optional configuration | optional configuration | optional configuration | optional configuration | |

| electron microscope | optional configuration | optional configuration | optional configuration | optional configuration | optional configuration | optional configuration | |

| G-Lift It is used for auxiliary loading of the backboard and can be equipped with 1 set for each equipment. | optional configuration | No configuration required | No configuration required | No configuration required | No configuration required | optional configuration | |

| Automatic loading system | No configuration required | No configuration required | No configuration required | No configuration required | No configuration required | optional configuration | |

| Integrated compressed air system | optional configuration | optional configuration | optional configuration | optional configuration | optional configuration | optional configuration | |

| Voltage regulator | optional configuration | optional configuration | optional configuration | optional configuration | optional configuration | optional configuration | |

| Laser case plus air conditioner Generally no air conditioning is required, and it is optional in the tropics. | optional configuration | optional configuration | optional configuration | optional configuration | optional configuration | optional configuration | |

| 6KW Equipped with Gemany Precitec Laser Head | optional configuration | optional configuration | optional configuration | optional configuration | optional configuration | optional configuration | |

| Precitec laser head added laser head side blow module | optional configuration | optional configuration | optional configuration | optional configuration | optional configuration | No configuration required | |

| 150mm focus distance Precitec laser head | optional configuration | optional configuration | optional configuration | optional configuration | optional configuration | No configuration required | |

Fiber Laser Cutting Machine display

Application:

GRS fiber laser cutting machines are widely used in manufacturing Billboard, Advertising,Signs,Signage,Metal Letters,LED Letters,Kitchen Ware,Advertising Letters, Sheet Metal Processing,Metals Components and

Parts,Ironware,Chassis,Racks & Cabinets Processing,Metal Crafts,Metal Art Ware,Elevator Panel Cutting,Hardware, Auto Parts,Glasses Frame,Electronic Parts,Nameplates,etc.

Production flow chart

Certification

Activity Customer

Packaging details

Factory introduction

GLORIOUS ,AKA, "GRS", represents the ultimate pursuit of Gorgeous Reliable and Smart. GLORIOUS Laser is a high-tech enterprise specializing in the R&D, manufacturing and marketing of intelligent laser equipment. GLORIOUS laser, driven by technology source power, adheres to the innovation development strategy; attach importance to talent cultivation so as to provide advanced technology and reliable products.GLORIOUS has obtained more than 100 R & D patents including Reddot Award and IF Award, GLORIOUS owns 208 professional R & D personnel and a production base covering an area of 100,000 square meters, and strictly executes the product quality control process. With "advanced technology and reliable products", GLORIOUS laser brings long-term and stable benefits to customers.

P4: Company Tenet - Fast Fast" is one of our business tenets. GLORIOUS will respond positively to and meet customers' needs immediately, and dedicated to solve problems for customers with enough patience as soon as possible.

Service

One-stop business chain service support system

With an international service team with rich experience and excellent skill, company is committed to build a complete service guarantee system, which is professional, fast, efficient and comprehensive. Every consumer in overseas would receive a full-process service guarantee including pre-sales, on sale and after sales through the way of markets, spare parts, training service and technical support.

1) Market Service

Service Mode : Stationary Point + Circuit Service

Long-term Stationary Point Service

Short-term Circuit Technology Support Service

Service Process: Standard, High Efficient, Seasonable

Service Image: Professional, Unified

2) Spare Parts Service

Spare Parts Guarantee Measures: Dealer+ Spare Part Warehouse

100% original spare parts assure good quality;

Bar-code system adopted in the whole process assures accuracy and promptness;

Professional and accurate package and logistics assure safe and relieved transportation.

3) Training Service

Characteristic Training Mode: invite the technicians of dealers to factory for training, send engineers to dealers for training;

A full range of training tools, multi-language training materials, vivid training video;

Professional training teachers with rich service experience and good communication capability;

One-to-one special assignment training;

Remote online network training;

4) Technical Support

The whole process Technology support covers on sale and after-sale service.

Terms of the deal:

1). Delivery: 20 days for normal orders

2). Price: We have price on basis FOB Qingdao and CIF your destination for your choice

3). Payment terms for first order:

-----T/T 30% deposit and balance before shipment

-----100% L/C at sight

4). Payment for long terms cooperation of good reputation partners, we have SINOSURE insurance for our VIP clients, and we can offer credit service after we familiar with each other. We are looking for partnership for long-term business

FAQ:

Why choose us?

1). The quality is guaranteed due to strong technical support ,first class component ,advanced production line and strict quality control system.

2). Be leading Expert in global market for more than 5 years, China Famous Export Brand recommended by CCCME (China Chamber of Commerce for Import and Export of Machinery and Electronic Products)

3). One-stop service with a large spare parts warehouse and professional service team .No matter where you are, you are guaranteed of Eurostar' s warm reception, trustworthy and efficient professional services and persistent care.

How Shipment?

We have worked with many world famous shipping carriers and can arrange shipment to any country in the world, it can save your time and money. We can provide airfreight and ocean service.

What is the machine advantage? Why I choose from you ?

A: Adopting world famous brand engine and parts, ensure long life service, all the structure parts are produced and checked by our engineers.Each machine is carefully tested before send to customer.Warranty time for 1 year or 1200 working hours.

How many units can be put in container?

A: 1-2 units can be in a 20ft container, 2-3 units can be in a 40HQ container.will be fixed with wire ropes.

Are you able to export less than 1 container of mini excavator ? And what's the wooden box's dimension and total weight ?

A:Yes ,if 1 unit or 2 units mini excavator machine could shipment by LCL, wooden box; if 4 unit or more than 4 units suggest used 20ft container. If do not have trailer, the wooden box dimension is 2.8x1.12x1.4m , about 4.3m3; if have trailer the wooden box dimension is 2.8x1.4x1.8m,about 7.54m3. Total weight about 1000kg.

Contact us

Mr. Duke Zhang

Shandong Euro Star Machinery Manufacture Co., Ltd.

Add: 198 Changning Street, Fangzi District, Weifang City, Shandong Province,P.R.C.

Web:eurostartractor.en.made-in-china.com

EUROSTAR CUSTOMERS ALL OVER THE WORLD